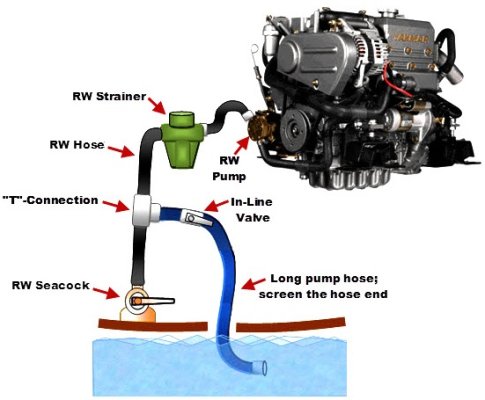

I've been thinking about this idea of using the engines raw water pump in an emergency, and I see some real challenges with that idea.

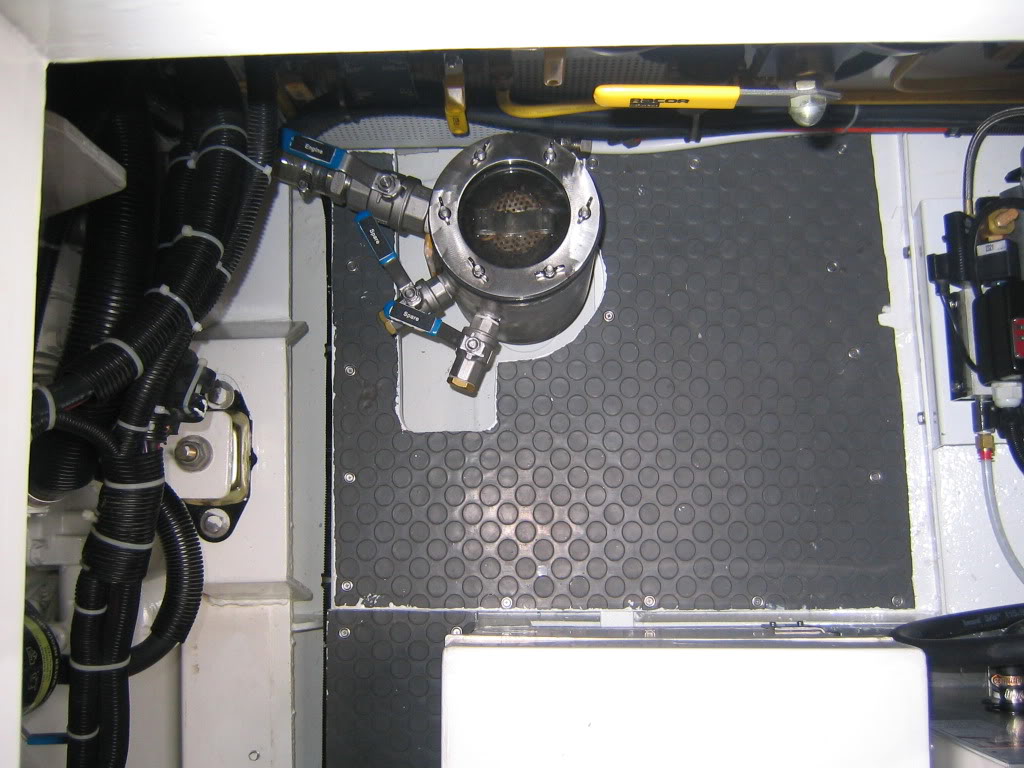

1. We're assuming that you can actually get to the valves in an emergency.

2. Unless the engine pump is undersized for the emergency, you're going to run dry. Then unless you're paying super close attention (with everything else that'll be going on) you're going to burn your engines pump impeller, possibly rendering the boat dead in the water.

The more I think about it, the more I like the AC powered pump. The one I posted earlier will move 95 GPM or 5700 GPH at a 5' head. Thats allot of water! More than most engine pumps. It takes approx 7 amps AC, which many of our boats have available using either an inverter or generator. You could also rig the pump up like a standard bilge pump with a on/auto mode switch. This would allow it to cycle, freeing you up to try to find and fix the source of the flooding.

I think the key here is early detection. Bells, lights, buzzers to tell you that you need to take action before the water gets to a point where it overcomes your electrical system.