Bilgewater

Senior Member

- Joined

- Jun 20, 2011

- Messages

- 276

- Location

- USA

- Vessel Name

- Sunset Lady

- Vessel Make

- 1975 Chris Craft 35 Aft Cabin

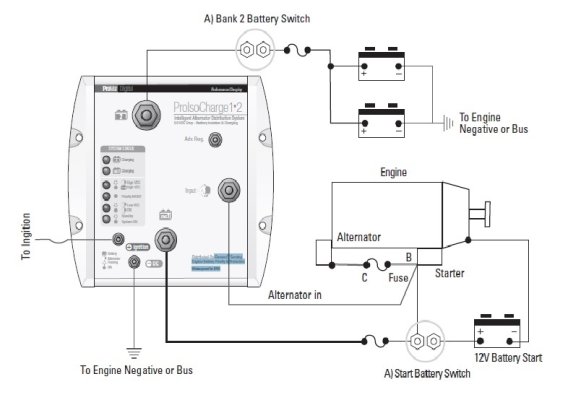

I'm confused about the alternator set up my two Perkins. Original 55 amp unit. (hope to upgrade when $$$ come available) The white power wire goes from the alt to the amp meter on the main panel. Then it becomes a red wire that goes back to the solenoid on the starter. I'm thinking that after the engine starts, the alternator will charge up the starting battery back through the solenoid and battery cable. My problem is how to wire up the ProMariner Isocharger to charge the house bank while underway. House bank is 6 6v golf cart batteries, about 700 amp/hrs total. While underway I use them through an 1500 watt inverter to power the fridge. I bought the Isocharger because it can take two inputs and charge 4 banks of batteries without me having to mess with it. I was thinking of cutting the red wire, and splicing another wire to it and run it to the input terminal on the Isocharger. I'm not sure what consequences might happen. Would I be safer to run a cable from the starting battery positive terminal to the Isocharger input stud, and then a cable from the charger to the house bank? All this heat is frying my logic process.

![specs_engine[1].jpg](/data/attachments/20/20430-f469da4a3e2cde867680e77df91e9567.jpg)

I'll do that, Ed. And welcome to the forum. BTW, I keep my boat down the road from you and used to berth at the Sacto Bay Club.

I'll do that, Ed. And welcome to the forum. BTW, I keep my boat down the road from you and used to berth at the Sacto Bay Club.