MurrayM

Guru

A tip and a heads up to future new owners of the LEHR 9.9 propane outboards on how to bleed the air from the lines;

1) Get a paperclip,

2) Take the cowling off,

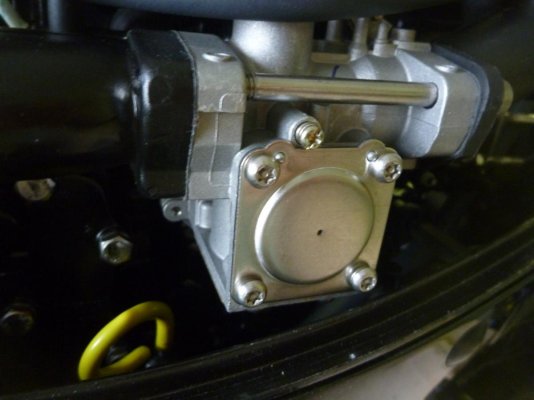

3) Find the square metal plate held by 4 screws with a small hole in the middle,

4) Attach and open the propane tank and lines,

5) Push the end of the paper clip gently into the hole...you'll hear hissing...and keep pushing until you get a whiff of propane, (I had to keep pressing for what seemed a couple minutes),

6) Give the starter cord a few pulls.

Ours started on about the third pull

**Kudos to HopCar**

1) Get a paperclip,

2) Take the cowling off,

3) Find the square metal plate held by 4 screws with a small hole in the middle,

4) Attach and open the propane tank and lines,

5) Push the end of the paper clip gently into the hole...you'll hear hissing...and keep pushing until you get a whiff of propane, (I had to keep pressing for what seemed a couple minutes),

6) Give the starter cord a few pulls.

Ours started on about the third pull

**Kudos to HopCar**

Attachments

Last edited: