awpptdt

Senior Member

- Joined

- Nov 7, 2010

- Messages

- 167

- Location

- U.S.A.

- Vessel Name

- Donnchaidh

- Vessel Make

- Marine Trader 40' sedan

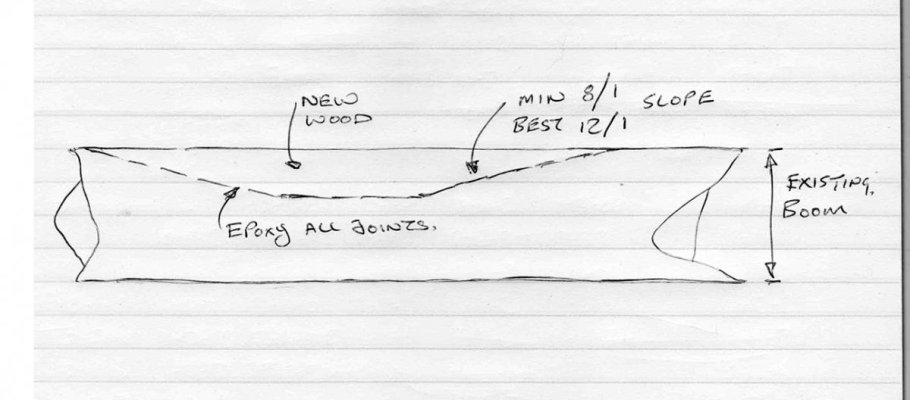

The boom on my Marine Trader 40' sedan has a soft ie  rotten spot. It is half way along the boom, on the bottom half, about 18" long and goes into the boom thickness about half way in about 1/4 of the rotten area and is 2" wide at it's widest

rotten spot. It is half way along the boom, on the bottom half, about 18" long and goes into the boom thickness about half way in about 1/4 of the rotten area and is 2" wide at it's widest . The boom is completely dry. Options, 1. Impregnate the area with epoxy, the boom is made of mahogany, 2. Build a new one of treated wood or build one of aluminum. Ok, what say you gang,

. The boom is completely dry. Options, 1. Impregnate the area with epoxy, the boom is made of mahogany, 2. Build a new one of treated wood or build one of aluminum. Ok, what say you gang, . Thanks, J.T.Duncan.

. Thanks, J.T.Duncan.

rotten spot. It is half way along the boom, on the bottom half, about 18" long and goes into the boom thickness about half way in about 1/4 of the rotten area and is 2" wide at it's widest

rotten spot. It is half way along the boom, on the bottom half, about 18" long and goes into the boom thickness about half way in about 1/4 of the rotten area and is 2" wide at it's widest . The boom is completely dry. Options, 1. Impregnate the area with epoxy, the boom is made of mahogany, 2. Build a new one of treated wood or build one of aluminum. Ok, what say you gang,

. The boom is completely dry. Options, 1. Impregnate the area with epoxy, the boom is made of mahogany, 2. Build a new one of treated wood or build one of aluminum. Ok, what say you gang,

. I have decided to build a new boom out of wood. I am leaning towards Ash as the perferred material

. I have decided to build a new boom out of wood. I am leaning towards Ash as the perferred material