On The Rocks

Senior Member

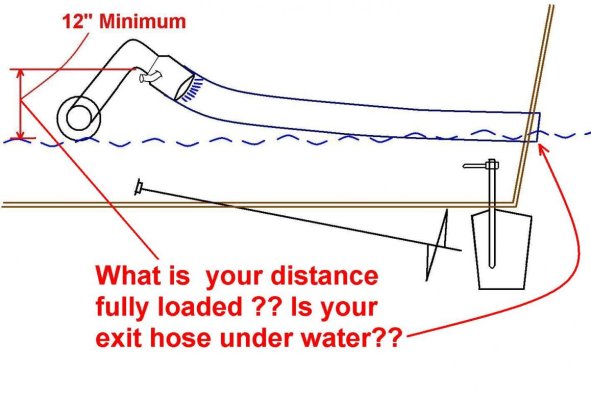

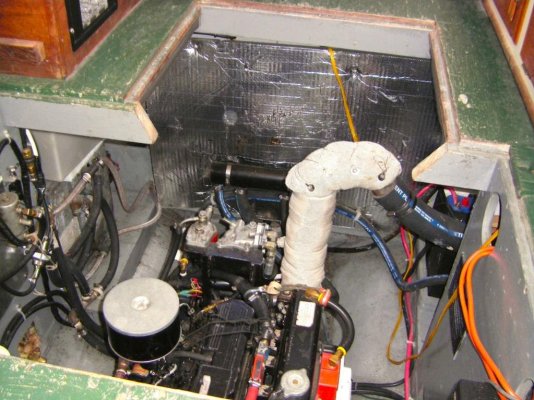

Looking at the exhaust on my Gulf Star 36 Trawler with twin 4-154 Perkins (60 hp). The exhaust manifold/water injection elbow is 2" diameter and about 9-10" above water line. Attached to the elbow is 4" diameter hose running along the chine of the hull aft to the mufflers and out through the transom. The mufflers are not water lift units and they are mounted about 4-6" above the lowest point of the exhaust hose. My concern is that when I disconnected the hose from the manifold the standing water level in the hose was only about 12" from the exhaust manifold. Although I haven't had a problem it seems a little close for comfort. I've been thinking of raising the height of the injection point. My questions are:

Ideas for sourcing injection elbows?

Is the 4" hose & muffler overkill for this engine? My Perkins guy says the exhaust should be 2" all the way to the transom. The 2" would be easier to route but I don't want to create a backpressure problem.

Does anyone know the size and configuration Gulf Star used?

Starboard

Port

Ideas for sourcing injection elbows?

Is the 4" hose & muffler overkill for this engine? My Perkins guy says the exhaust should be 2" all the way to the transom. The 2" would be easier to route but I don't want to create a backpressure problem.

Does anyone know the size and configuration Gulf Star used?

Starboard

Port