jcwyatt

Veteran Member

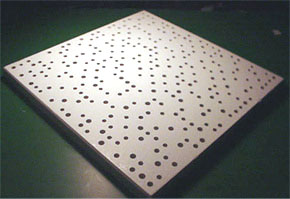

Does anyone know a source for this acoustic tile in my engine room? I would like to replace a number of missing and damaged tiles, without having to retile both entire engine rooms. I have searched on google and cannot find a vendor. It seems to be a common tile in 70's and 80's boat engine rooms.

Thanks

Thanks