stevensibs

Senior Member

- Joined

- Mar 21, 2011

- Messages

- 172

- Location

- USA

- Vessel Name

- Still Sibsie

- Vessel Make

- 42' Bristol Trawler

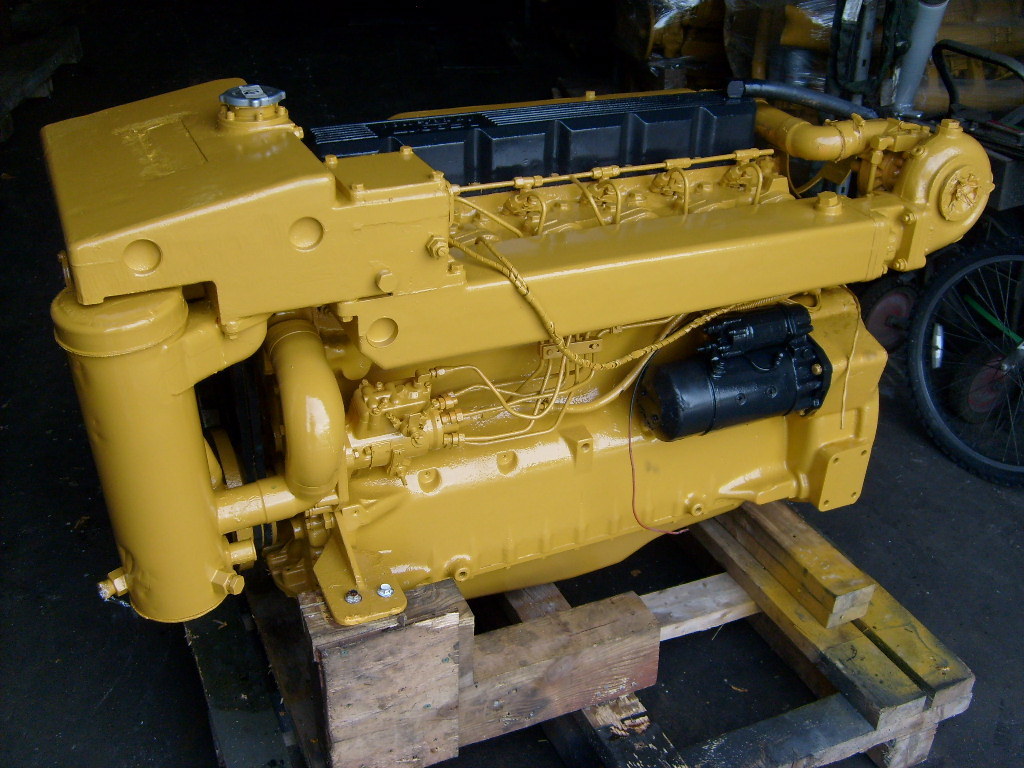

I have an urgent question; I think I already know the answer. I have the chance to buy a new, leftover John Deere 6068 TFM that is keel cooled. Can I change it ti heat exchanger cooling? If I can, I'm buying this motor.