meridian

Guru

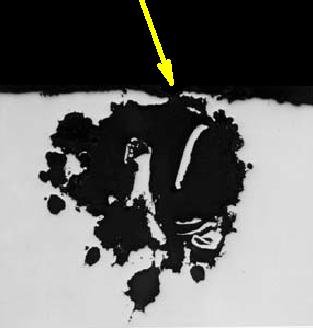

I was finally able to pull the shaft on my Albin 36'. Since many of the TT's were built using the same design, I’m putting the question up here. The cutless bearing case is attached to the hull using (2) ss threaded studs. The stuffing box base is attached to the opposite end using (4) ss screws about ½ x 5”. I was able to get these out but I don’t know what was used to seal the case and base to the hull.

Any ideas

Any ideas