Whistledoc

Veteran Member

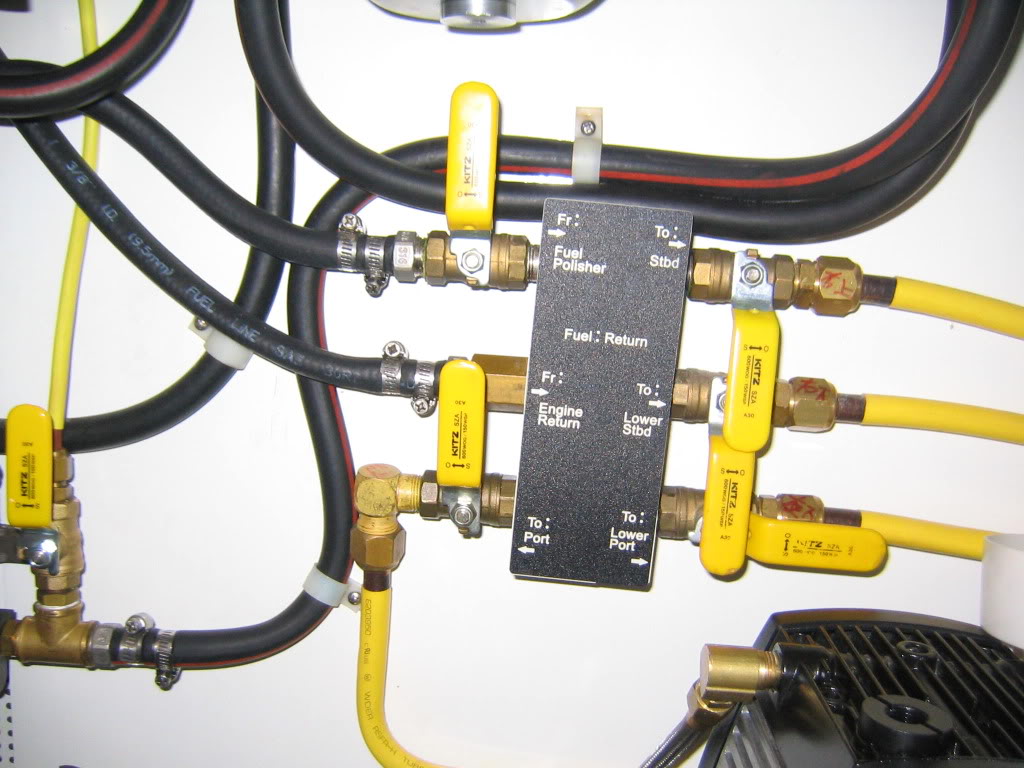

I am having a problem presumably with fuel supply to my generators. We have two, a 15 and a 40. Don't use the 40 very often but we have 120,000 BTUs of AC and cook with electriicity , and have some big compressors, etc., so sometimes in the summertime we need it. Both gensets are relatively new, both with less than 1000 hours. The fuel supply comes from a supply manifold using the same valve as the engines. From there it runs to a dedicated genertor Racor and then aft where the two gens are located. There is a 20 foot run of 3/8's copper from the Racor to where the 15 "t's" off and from there it runs to the 40, about another 15 feet.

The problem is that I have great difficulty getting them to start even with a boost pump at the manifold running. Cold weather, warm weather... no difference. Doesnt seem to make any difference if the gens have been used a lot recently or not. Once they start they will run all day long and never miss a lick. But when I turn then off, sometimes they won't start again even is still warm. On the other hand sometimes when they have been sitting for a few days unused they fire right up. Both are Westerbekes and have fuel pumps that are energized by the preheat switch. I have changed all of the filters, racor and primary and seconday filters on the gensets. I do not have a problem with either of the Cummins propulsion engines. They fire right up and share the same supply but have their own Racors. .

Someone has suggested that one generator is sucking the fuel out of the other and that using some check valves might help but I have not tried this as someone else said that the fuel pumps dont generate enough negative pressure to flow through a check and it would restrict fuel flow. Another person suggested that the long run from the manifold to the generators was the problem but even with the boost pump running it continues to be a problem. Any one have any brilliant ideas?

I cannot remember if this is a new problem but it did not seem to be a problem when we launched the boat so I suspect its a new problem. Any help would be welcomed.

The problem is that I have great difficulty getting them to start even with a boost pump at the manifold running. Cold weather, warm weather... no difference. Doesnt seem to make any difference if the gens have been used a lot recently or not. Once they start they will run all day long and never miss a lick. But when I turn then off, sometimes they won't start again even is still warm. On the other hand sometimes when they have been sitting for a few days unused they fire right up. Both are Westerbekes and have fuel pumps that are energized by the preheat switch. I have changed all of the filters, racor and primary and seconday filters on the gensets. I do not have a problem with either of the Cummins propulsion engines. They fire right up and share the same supply but have their own Racors. .

Someone has suggested that one generator is sucking the fuel out of the other and that using some check valves might help but I have not tried this as someone else said that the fuel pumps dont generate enough negative pressure to flow through a check and it would restrict fuel flow. Another person suggested that the long run from the manifold to the generators was the problem but even with the boost pump running it continues to be a problem. Any one have any brilliant ideas?

I cannot remember if this is a new problem but it did not seem to be a problem when we launched the boat so I suspect its a new problem. Any help would be welcomed.

Last edited by a moderator: