- Joined

- Oct 1, 2007

- Messages

- 7,331

- Location

- Texas

- Vessel Name

- Floatsome & Jetsome

- Vessel Make

- Meridian 411

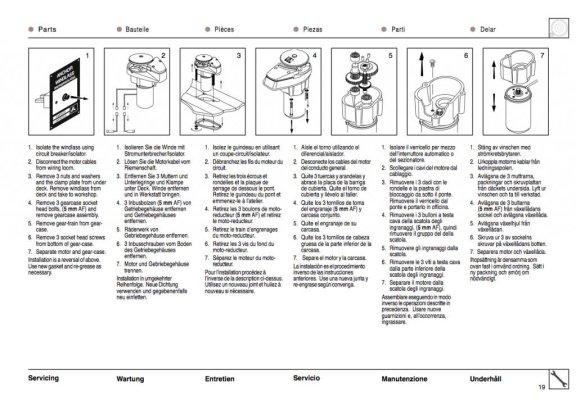

I was crankin' the anchor in on Sunday and everything was fine and then...not so fine.* The windlass slowed down like it was binding or something.* So I went foward expecting to find something jammed but I didn't.* Next thing you would think is that it is not getting enough voltage but the way in which this suddenly occured and the fact that ALL things on this boat are powered by 2 group 31s and ALL things were working just fine(except windlass) would most likely rule out a battery problem.* I guess it could be a voltage(bad connection) problem but I really don't think so.* The DOWN operation works just fine although down is never really loaded.*

Whaday'all think?* Motor?

Whaday'all think?* Motor?