You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Swift Trawler Winterization list

- Thread starter boater3

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

Eddieandgail

Veteran Member

Thank you very much for the advice!

Regarding the engine/genset winterization, if I just pour into the strainer then what happens with the seawater between the thru-hull / seacock and the strainer? I think that can freeze and cause damage?

I close strainer, use a shopvac to empty and fill with antifreeze and since my genset use an external pump as it has no raw water pump so I winterize using its own pump. If boat sits in water, the hull side of sea cock is in water and the bilge side has the antifreeze from the strainer

Regarding the hot water heater exchange loop, its coolant from the engine resevoir or where does it originate? I am worried that if I continue to run the engines, there is hot coolant circulating in the loop but the hot water heater is empty and thus nothing to heat (or in the case of filling it with antifreeze, its heating antifreeze which may hurt the antifreezing abilities). I just don't want to damage my hot water heater.

That would be engine coolant circulating. Only need to be concerned if the electric heating element is on with no liquid to heat. Usually worst case is a replacement element.

Regarding adding antifreeze into the water tanks, what happens to the hose between the tanks and the pump? Water left in that section can freeze?

My favorite is a friend that blows out his freshwater system with compressed air then pours a couple gallons of cheap vodka in tanks. Spring commissioning must be a lot of fun

Regarding the city water connection, how can it back flow if it has nowhere to exit? I think the city water connection is a one-way valve? Unless I can somehow figure out how to open it so antifreeze shoots out of the connection...

I have $39 Harbor Freight 12v pump with garden hose fittings. I made up a couple hoses for various systems. I do city water first. Turn off water pressure pump, connect my 12v HF pump to regulator, open a faucet and a gallon later should have pink from faucet as it only has to travel to a T near the house water pump

Thank you for the great idea on blowing out the shaft line and closing while blowing. I will have to look at my larger thruhulls and see if I can drain the ball cavity. I would simple close, unscrew, drain, and leave closed?

Thanks so much!!

After 2 seasons of ownership I discovered an AC freshwater flush from house water and I used it to drain my water tanks through the 3 AC systems and then use the HF pump to run pink through the units through the same hoses. I have a manifold and long runs so I used 5 gallons to be very pink. I had to remember washing machine, raw water wash down pump, dockside water filter, engine room freshwater faucet and transom shower

Eddie and Gail

So I ordered a drum bung wrench to try to open the red access port but it did not work as it kept slipping. I then tried using my reverso oil change pump to suck water out but that did not work as I assumed it wouldn't. Finally, I got 1/2" hose, inserted into shopvac hose, taped a seal as best as I could, then taped the other end to a skinny piece of wood, and was able to suck out most of the remaining water through the fill port on the tank. Somewhere between 5-10 gallons per tank of water came out.

I then used the cheap Camco blow out fitting through the shore water connection, blew out all of the fixtures, then I added the antifreeze to the tanks, and ran it through all the fixtures. Not happy about adding antifreeze into the tanks etc but I did not see another way without easy accessibility to the T connection. I think the tanks took ~7 gallons of antifreeze each before the freshwater pump would start pumping the pink stuff through (this is with the hot water heater bypassed). I used an extra gallon or two to make sure everything was good to go so 16 gallons total just on the freshwater system.

I then used the cheap Camco blow out fitting through the shore water connection, blew out all of the fixtures, then I added the antifreeze to the tanks, and ran it through all the fixtures. Not happy about adding antifreeze into the tanks etc but I did not see another way without easy accessibility to the T connection. I think the tanks took ~7 gallons of antifreeze each before the freshwater pump would start pumping the pink stuff through (this is with the hot water heater bypassed). I used an extra gallon or two to make sure everything was good to go so 16 gallons total just on the freshwater system.

Mystery

I'm assuming that blue hose is accessible at the water pump.

You might consider installing a winterization valve there which would let you pump pink thru pump and FW plumbing / fixtures w/o having to put the lg vol of pink into the tank.

Then you need to protect the T fitting and blue tubing. That could be done by blowing compressed air back into the tank and pumping a smaller vol of pink back to the tanks.

It would take a few fittings but would result in much less pink in the tanks you have to flush.

I'm assuming that blue hose is accessible at the water pump.

You might consider installing a winterization valve there which would let you pump pink thru pump and FW plumbing / fixtures w/o having to put the lg vol of pink into the tank.

Then you need to protect the T fitting and blue tubing. That could be done by blowing compressed air back into the tank and pumping a smaller vol of pink back to the tanks.

It would take a few fittings but would result in much less pink in the tanks you have to flush.

Adding to list:

- Add distilled water to batteries

- Turn off breakers for winterized pumps etc to prevent accidental operation and to remember to commission things before use

- Blow out water from sea water hoses through thruhulls using compressor/shop vac attachment

Removing from list:

- Fuel stabilizer: I have decided against introducing anything unnecessary to the diesel

- Add distilled water to batteries

- Turn off breakers for winterized pumps etc to prevent accidental operation and to remember to commission things before use

- Blow out water from sea water hoses through thruhulls using compressor/shop vac attachment

Removing from list:

- Fuel stabilizer: I have decided against introducing anything unnecessary to the diesel

Last edited:

Working on the engine winterization now...

My plan:

- Connect the 1.5" raw water intake hose to some additional length of 1.5" hose using a coupler in order for it to reach into a five gallon bucket with antifreeze. I was originally planning to use a Sea Flush funnel kit or TRAC Flush Cap but neither seem to be compatible with the Vetus 1320 sea water strainers.

- Blow out the line from the strainer to the thruhull using a shop vac, close the seacock once done. May also pour antifreeze into this hose.

- Run engines at idle sucking up the antifreeze until I see the proper color exiting the exhaust. I am guessing at least five gallons per engine and maybe an extra gallon or two for good measure.

Is that sufficient to winterize the Volvo D4?

Some additional questions:

1. I read online about siphon breaks and introducing antifreeze at a height higher than the engines. I don´t see any siphon breaks. My seawater strainers are mounted a bit high probably at the height of the tops of the engines themselves. I am used to seawater strainers being mounted much lower. Do I have to worry about any water/antifreeze siphoning back into the engines? Should I make sure the bucket of antifreeze is located on the engine room floor versus up above the engines?

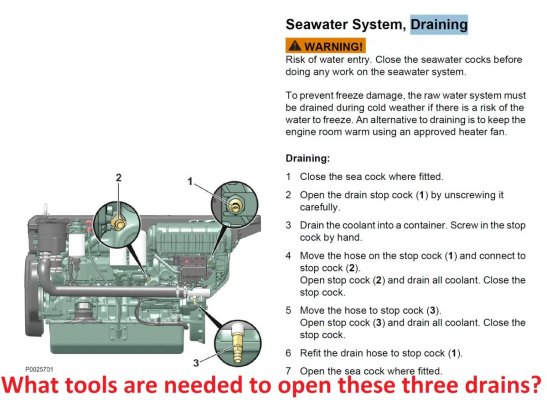

2. In the attached screen capture from the manual, should I drain at these three drains? Are those raw water or coolant drains? It is unclear as the section is titled "Seawater draining" but the steps reference "coolant". If that is seawater, does it still need to be drained even when introducing antifreeze as I plan to? If so, what tools do I need to open those three fittings?

3. During spring commissioning, is there a way to prime the seawater system (like is done to prime/bleed the fuel system after filters drained/changed)? If I drain seawater, I would be worried of the impellers running dry and breaking apart. What about when changing the zinc anodes on the engines as some seawater drains out during that change?

4. What is the drain in the other picture I have attached? I have a separate drain connection I use for oil changes and trying to figure out what this one is for...

5. Finally, any thoughts on using a diesel fuel stabilizer? I have always used on my gasoline engines but it seems there are two schools of thought for diesel: a) leave it alone, b) add stabilizer. The diesel will sit 5-6 months in cold temperatures.

My plan:

- Connect the 1.5" raw water intake hose to some additional length of 1.5" hose using a coupler in order for it to reach into a five gallon bucket with antifreeze. I was originally planning to use a Sea Flush funnel kit or TRAC Flush Cap but neither seem to be compatible with the Vetus 1320 sea water strainers.

- Blow out the line from the strainer to the thruhull using a shop vac, close the seacock once done. May also pour antifreeze into this hose.

- Run engines at idle sucking up the antifreeze until I see the proper color exiting the exhaust. I am guessing at least five gallons per engine and maybe an extra gallon or two for good measure.

Is that sufficient to winterize the Volvo D4?

Some additional questions:

1. I read online about siphon breaks and introducing antifreeze at a height higher than the engines. I don´t see any siphon breaks. My seawater strainers are mounted a bit high probably at the height of the tops of the engines themselves. I am used to seawater strainers being mounted much lower. Do I have to worry about any water/antifreeze siphoning back into the engines? Should I make sure the bucket of antifreeze is located on the engine room floor versus up above the engines?

2. In the attached screen capture from the manual, should I drain at these three drains? Are those raw water or coolant drains? It is unclear as the section is titled "Seawater draining" but the steps reference "coolant". If that is seawater, does it still need to be drained even when introducing antifreeze as I plan to? If so, what tools do I need to open those three fittings?

3. During spring commissioning, is there a way to prime the seawater system (like is done to prime/bleed the fuel system after filters drained/changed)? If I drain seawater, I would be worried of the impellers running dry and breaking apart. What about when changing the zinc anodes on the engines as some seawater drains out during that change?

4. What is the drain in the other picture I have attached? I have a separate drain connection I use for oil changes and trying to figure out what this one is for...

5. Finally, any thoughts on using a diesel fuel stabilizer? I have always used on my gasoline engines but it seems there are two schools of thought for diesel: a) leave it alone, b) add stabilizer. The diesel will sit 5-6 months in cold temperatures.

Attachments

I've seen a lot of posts devoted to winterizing the engines and fresh water system, but the only mention of the sanitation system was this in the first post:

Waste:

- Ensure waste tank is not full

- Pour antifreeze into toilets, flush

- Does anything need to be done to the overboard waste discharge other than ensuring the thruhull is closed?

Yes!! Not only to the overboard discharge but the entire system...why would you even think of laying up the boat for the winter with any sewage in tank??

[FONT="][FONT="]SANITATION SYSTEM[/FONT]

[/FONT][FONT="] [/FONT][FONT="][FONT="]Step 1/ Prep for winterizing:

[/FONT][/FONT]

[FONT="][FONT="]Pump holding tank out, then rinse thoroughly to flush out any sludge. This does not require filling the tank and can even be done with sea water. Here’s how: [/FONT][/FONT]

[FONT="] [FONT="]Put enough water into the tank via the deck pumpout fitting—because that sends the water into the tank at the bottom to stir up any sludge and hold it in suspension so it can be flushed out-- to cover the bottom to a depth of at least three inches. Pump that out. Repeat…repeat…repeat…till you’re pumping out clean water. Then add water one more time and turn on the macerator to rinse it out along with the overboard discharge plumbing. [/FONT]

[FONT="]Alternatively, you can use a washdown pump to do the whole job. Stick the nozzle into the deck pumpout out fitting and turn on the water. When the depth reaches a couple of inches, leave the water running and turn on the macerator Let both run till the water runs clean (it may be best to do this offshore outside the “3 mile limit”).[/FONT]

[/FONT][FONT="] [/FONT][FONT="][FONT="]Btw, this should be done at least 2-3x a season, more often if live aboard or use your boat year round.[/FONT][/FONT]

[FONT="]

[FONT="]Now you’re ready to winterize the system. [/FONT]

[/FONT]

[FONT="]Sea water toilet, manual or electric:

[/FONT]

[FONT="]Just flushing antifreeze through the bowl will NOT protect the intake line, the toilet pump or the bowl...it'll only go out the discharge to the tank. To protect the whole system, it's necessary to close the toilet intake through-hull, disconnect inlet hose and stick it in a gallon of non-toxic ("the pink stuff") antifreeze. Pump the whole gallon through the system into the holding tank. Do not reconnect head intake hose to the through-hull. [/FONT]

[FONT="]

[FONT="]Fresh water toilet[/FONT][FONT="]: If your toilet uses onboard pr[/FONT][FONT="]essurized fresh water, you winterized it when you winterized your fresh water system. All that remains is, flush the appropriate amount of non-toxic antifreeze ("the pink stuff") down the toilet into the tank and you’re done.[/FONT]

Do not use antifreeze in an ElectroScan, Lectra/San, PuraSan, or any other Type I or Type II MSD. Follow manufacturers instructions to winterize all Type I and II MSDs.

[FONT="]After the boat comes out of the water, open all the sea cocks to drain any trapped water.[/FONT]

[/FONT][FONT="] [FONT="]And you’re done.[/FONT][/FONT]

[FONT="][FONT="]

[/FONT][/FONT]

[FONT="][FONT="]--Peggie[/FONT][/FONT]

[FONT="][FONT="]"If you can't explain it to a six year old, you don't completely understand it yourself." --Albert Einstein

[/FONT][/FONT]

Waste:

- Ensure waste tank is not full

- Pour antifreeze into toilets, flush

- Does anything need to be done to the overboard waste discharge other than ensuring the thruhull is closed?

Yes!! Not only to the overboard discharge but the entire system...why would you even think of laying up the boat for the winter with any sewage in tank??

[FONT="][FONT="]SANITATION SYSTEM[/FONT]

[/FONT][FONT="] [/FONT][FONT="][FONT="]Step 1/ Prep for winterizing:

[/FONT][/FONT]

[FONT="][FONT="]Pump holding tank out, then rinse thoroughly to flush out any sludge. This does not require filling the tank and can even be done with sea water. Here’s how: [/FONT][/FONT]

[FONT="] [FONT="]Put enough water into the tank via the deck pumpout fitting—because that sends the water into the tank at the bottom to stir up any sludge and hold it in suspension so it can be flushed out-- to cover the bottom to a depth of at least three inches. Pump that out. Repeat…repeat…repeat…till you’re pumping out clean water. Then add water one more time and turn on the macerator to rinse it out along with the overboard discharge plumbing. [/FONT]

[FONT="]Alternatively, you can use a washdown pump to do the whole job. Stick the nozzle into the deck pumpout out fitting and turn on the water. When the depth reaches a couple of inches, leave the water running and turn on the macerator Let both run till the water runs clean (it may be best to do this offshore outside the “3 mile limit”).[/FONT]

[/FONT][FONT="] [/FONT][FONT="][FONT="]Btw, this should be done at least 2-3x a season, more often if live aboard or use your boat year round.[/FONT][/FONT]

[FONT="]

[FONT="]Now you’re ready to winterize the system. [/FONT]

[/FONT]

[FONT="]Sea water toilet, manual or electric:

[/FONT]

[FONT="]Just flushing antifreeze through the bowl will NOT protect the intake line, the toilet pump or the bowl...it'll only go out the discharge to the tank. To protect the whole system, it's necessary to close the toilet intake through-hull, disconnect inlet hose and stick it in a gallon of non-toxic ("the pink stuff") antifreeze. Pump the whole gallon through the system into the holding tank. Do not reconnect head intake hose to the through-hull. [/FONT]

[FONT="]

[FONT="]Fresh water toilet[/FONT][FONT="]: If your toilet uses onboard pr[/FONT][FONT="]essurized fresh water, you winterized it when you winterized your fresh water system. All that remains is, flush the appropriate amount of non-toxic antifreeze ("the pink stuff") down the toilet into the tank and you’re done.[/FONT]

Do not use antifreeze in an ElectroScan, Lectra/San, PuraSan, or any other Type I or Type II MSD. Follow manufacturers instructions to winterize all Type I and II MSDs.

[FONT="]After the boat comes out of the water, open all the sea cocks to drain any trapped water.[/FONT]

[/FONT][FONT="] [FONT="]And you’re done.[/FONT][/FONT]

[FONT="][FONT="]

[/FONT][/FONT]

[FONT="][FONT="]--Peggie[/FONT][/FONT]

[FONT="][FONT="]"If you can't explain it to a six year old, you don't completely understand it yourself." --Albert Einstein

[/FONT][/FONT]

Last edited:

Valve is to drain the coolant from the engine

Thanks. That will make it easier to change. I ordered test strips to check the status of the coolant. Fingers crossed I can get another year!

Harmony 34

Member

- Joined

- Dec 16, 2014

- Messages

- 8

- Location

- US

- Vessel Name

- Harmony

- Vessel Make

- Beneteau Swift Trawler 34

Overkill

Hi Mystery,

I now have a ST 44, previously had ST 34 for 6 years, both in Rhode Island for summer and winter (hauled out). Winterized fresh water system by bypassing hot water tank, draining it & using shop vac to clean up drained water, no antifreeze in tanks. Used hose to FW pump in bucket to pump A/F through system. Didn't bother draining tanks or hose from tank to pump. Never had a problem, despite winters below 0 degrees F. Rest of your list is good, but a lot of overkill.

Hi Mystery,

I now have a ST 44, previously had ST 34 for 6 years, both in Rhode Island for summer and winter (hauled out). Winterized fresh water system by bypassing hot water tank, draining it & using shop vac to clean up drained water, no antifreeze in tanks. Used hose to FW pump in bucket to pump A/F through system. Didn't bother draining tanks or hose from tank to pump. Never had a problem, despite winters below 0 degrees F. Rest of your list is good, but a lot of overkill.

some new items to add:

- remove engine air filters, put garbage bag over inlet ports on engine, taped tight, to prevent air flow to/from outside (another option is to inflate balls in the exhaust ports). also, tape over genset exhaust port.

- use garbage bags + tape to tape over the engine room air inlets on both sides (where the stainless grills are)

- i added more whale 15mm quick connect fittings to the fresh water system so i could isolate the exterior fixtures (fly bridge sink, transom shower, transom city water), blow them out with air, and keep the rest of the fresh water system going a bit longer

- tape over fuel fills with shrink tape just to make sure no moisture making it past o-rings/gaskets

- test coolant with refractometer to ensure freeze protection

- when doing oil samples, not only request TBN but also TAN to understand acidity in oil

- remove engine air filters, put garbage bag over inlet ports on engine, taped tight, to prevent air flow to/from outside (another option is to inflate balls in the exhaust ports). also, tape over genset exhaust port.

- use garbage bags + tape to tape over the engine room air inlets on both sides (where the stainless grills are)

- i added more whale 15mm quick connect fittings to the fresh water system so i could isolate the exterior fixtures (fly bridge sink, transom shower, transom city water), blow them out with air, and keep the rest of the fresh water system going a bit longer

- tape over fuel fills with shrink tape just to make sure no moisture making it past o-rings/gaskets

- test coolant with refractometer to ensure freeze protection

- when doing oil samples, not only request TBN but also TAN to understand acidity in oil

twistedtree

Guru

I don't think anyone has mentioned the deck drains. Unless the boat will be stored inside, I definitely would NOT cover the deck drains. I have seen decks flood, then freeze, and resulting cracked gel coat or worse. I would keep the drains clear, and check over the winter to be sure snow and ice isn't backing up.

And if the boat is stored inside, then I see no need to cover the drains either. Just no harm if you do.

It seems the issue you are trying to guard against are low spots in the drain lines. I think a little pink down the drains should protect them PROVIDED the boat is covered so no further water gets in. If the boat isn't covered, then I think you need to fix the drains. Probably easier said than done, but I don't see any other way to keep them from backing up.

And if the boat is stored inside, then I see no need to cover the drains either. Just no harm if you do.

It seems the issue you are trying to guard against are low spots in the drain lines. I think a little pink down the drains should protect them PROVIDED the boat is covered so no further water gets in. If the boat isn't covered, then I think you need to fix the drains. Probably easier said than done, but I don't see any other way to keep them from backing up.

I don't think anyone has mentioned the deck drains. Unless the boat will be stored inside, I definitely would NOT cover the deck drains. I have seen decks flood, then freeze, and resulting cracked gel coat or worse. I would keep the drains clear, and check over the winter to be sure snow and ice isn't backing up.

And if the boat is stored inside, then I see no need to cover the drains either. Just no harm if you do.

It seems the issue you are trying to guard against are low spots in the drain lines. I think a little pink down the drains should protect them PROVIDED the boat is covered so no further water gets in. If the boat isn't covered, then I think you need to fix the drains. Probably easier said than done, but I don't see any other way to keep them from backing up.

thanks for that thought, i was concerned about accumulated water in the drain hoses but i think you are right, better not to block

Engine winterization was easier than expected (first time I witnessed/did it on this boat). I changed the anodes ahead. Checked coolant freeze protection.

With mechanic help, I used the sea flush kit to blow out the line with a shop vac, he quickly closed the seacock. Then poured anti-freeze into strainer. It sucked it down a lot slower than what I imagined and was manageable. My backup was removing the hose and connecting it to a bucket but that would have been more work.

Removed air filters, garbage bag around empty hole to prevent air from passing through / exchanging.

Sealed engine room air inlet (grilles on both sides) & sealed blower ports on both sides of hull, to also prevent air exchange.

Generator was easy like last year with blowing out with sea flush/shop vac and pouring AF into strainer. Taped over the air exhaust port with some shrink tape.

With mechanic help, I used the sea flush kit to blow out the line with a shop vac, he quickly closed the seacock. Then poured anti-freeze into strainer. It sucked it down a lot slower than what I imagined and was manageable. My backup was removing the hose and connecting it to a bucket but that would have been more work.

Removed air filters, garbage bag around empty hole to prevent air from passing through / exchanging.

Sealed engine room air inlet (grilles on both sides) & sealed blower ports on both sides of hull, to also prevent air exchange.

Generator was easy like last year with blowing out with sea flush/shop vac and pouring AF into strainer. Taped over the air exhaust port with some shrink tape.

Last edited:

sea flush kit was also helpful in winterizing the hvac. i was able to blow air out through the thru-hull, close the valve, then blow out the salt water, then introduce AF via funnel. unfortunately the starboard side strainer was right under the exhaust hose so i had to improvise a little bit there.

winterizing the water system is still a total PITA. the boat, like most boats, sits in the water at an angle. therefore water pools at the rear of both water tanks and will not drain out by running the tap. an easy fix would've been to place the drains/connections in the rear of the tanks. my biggest concern was water sitting in the T valve that joins the tanks and then goes to the FW pump (if the T froze and cracked, it appears that it would require removal of the generator to access to repair ugh). it took 2-3 hours to do the FW water system: reconnect the bypassed outdoor fixtures, drain the tanks by opening fixture, blow out with air, drain hot water tank (i connected the drain to the sump), blow out hot water tank with air, shop vac out water stuck in the tanks, bypass the hot water heater, introduce AF into the tanks, run through fixtures, blow out AF, shop vac out AF, also had to do tha FW wash down pump, pour AF down all drains, open all fixtures. if the tanks were plumbed better, i simply would've probably blown everything out with air and not done anything with AF.

winterizing the water system is still a total PITA. the boat, like most boats, sits in the water at an angle. therefore water pools at the rear of both water tanks and will not drain out by running the tap. an easy fix would've been to place the drains/connections in the rear of the tanks. my biggest concern was water sitting in the T valve that joins the tanks and then goes to the FW pump (if the T froze and cracked, it appears that it would require removal of the generator to access to repair ugh). it took 2-3 hours to do the FW water system: reconnect the bypassed outdoor fixtures, drain the tanks by opening fixture, blow out with air, drain hot water tank (i connected the drain to the sump), blow out hot water tank with air, shop vac out water stuck in the tanks, bypass the hot water heater, introduce AF into the tanks, run through fixtures, blow out AF, shop vac out AF, also had to do tha FW wash down pump, pour AF down all drains, open all fixtures. if the tanks were plumbed better, i simply would've probably blown everything out with air and not done anything with AF.

ST44 BENETUEA 285

Member

Rh/lh props for sale, new st44

Hello ,

I am getting the word out to ST44 owners I have a set of new props, list retail new appox. $6000.00. Will sell for $5000.00 plus freight . I have all part numbers , invoices, details.

This is the first winter I will have my ST44 in the North. Below is a list of items that I thought of. Feel free to add/comment. Also, have some questions at the end.

Engines:

- Add fuel stabilizer to tanks, decide whether filling up or leaving empty, take on quick ride to mix, run through system

- Change oil/filters if due

- Change transmission fluid/filter if due

- Drain water from racors

- Drain engine mounted fuel filters

- Close thruhull, remove hose, place into bucket of water to flush, then switch to -50 or -100 engine antifreeze, run through, re-attach hose to thru-hull (keep closed)

Generator:

- Run generator after adding fuel stabilizer

- Change oil/filters if due

- Change coolant if due

- Drain water from racor

- Is there a way to drain the generator fuel filter? Is it a water separator?

- Close thruhull, remove hose, place into bucket of water to flush, then switch to -50 or -100 engine antifreeze, run through, re-attach hose to thru-hull (keep closed)

Freshwater system:

- Drain freshwater tanks (use sump that fits into the access holes to drain, if necessary)

- Drain hot water heater

- Install bypass on hot water heater heat exchange loop (this is in case you will run engines after water system is winterized because if you drain the hot water heater, it will either be empty or if you put antifreeze in it may damage the antifreeze?)

- Is the heat exchange loop coming from the engine to the hot water heater raw saltwater or is it coolant from the engine or coolant from somewhere else?

- Install bypass on hot water heater freshwater loop

- Add water system safe pink alcohol free antifreeze into both tanks (probably 5-10 gallons per tank??)

- Open all fixtures, run until pink flows out of both hot and cold (head sinks, head showers, transom shower, flybridge sink, kitchen sink)

- Pour antifreeze into drains (although probably not necessary unless you were draining the shower wands into the sinks instead of the shower drain)

- How does one winterize the city water connection that leads to the overall water system? Blow it out with an air attachment first?

HVAC:

- Close thruhull, jump pumps, place hose into bucket of fresh water, run to flush

- Switch to antifreeze, run through HVAC pumps/system

- Use turkey baster or similar to add antifreeze into HVAC pans, ensure it makes it through the minisumps and into the HVAC drain manifold

Waste:

- Ensure waste tank is not full

- Pour antifreeze into toilets, flush

- Does anything need to be done to the overboard waste discharge other than ensuring the thruhull is closed?

Misc (systems):

- Drain/winterize saltwater washdown thru-hull

- Winterize saltwater washdown pump/deck port

- Ensure windshield washer fluid is rated for freezing temps

- Shutdown, defrost, clean, dry out all fridges

- Winterize /store dinghy outboard

Misc:

- Consider one last wash / detailing of topsides and hull

- Plug / tape over deck drains on flybridge, deck, etc (maybe pour some antifreeze into them before taping)

- Check anodes, make sure sufficient for winter, if leaving shore power plugged in, ensure that galvanic isolator is functional

- Remove any cleaning fluids, toiletries, cooking items, etc that may freeze

- Open all cabinet doors, drawers, etc

- Hang damprid bags throughout bathrooms, staterooms, salon, etc

- Dry all exterior cushions, consider removing from boat

- Remove exterior wood tables (i.e. flybridge), store in cabin

- Remove grill pan, dispose

- Double up lines and fenders if leaving in water

- Remove all canvas, store

- Ensure propane tank is in off position and disconnected

- Install winter covers or shrink wrap

- Consider an engine room safe heater to keep temps above freezing (might need one in both engine room and genset compartment)

- Check on the boat regularly if stored afloat

- Trickle charge batteries over winter

Questions:

- Is the heat exchange loop coming from the engine to the hot water heater raw saltwater or is it coolant from the engine or coolant from somewhere else?

- Does anything need to be done to the overboard waste discharge other than ensuring the thruhull is closed?

- How does one winterize the city water connection that leads to the overall water system? Blow it out with an air attachment first?

- Should antifreeze be run through bilge pumps?

- Is it worth adding a hanging zinc? What should it bond/clip onto?

- Can the exhaust port be safely left open?

- Does anything special need to be done to thruhulls/seacocks other than closing them?

- What about the shaft thruhull, how to winterize?

- Any issue foreseen with leaving mast upright if shrink wrap can be installed around it? Or is it better to lower it, maybe rest it on a 2x4, and have it shrink wrapped over entirely? I guess I would be concerned with the weight of the 2x4 pressing on the deck?

Anything I am forgetting? Anything that should be done differently?

Thanks!

Hello ,

I am getting the word out to ST44 owners I have a set of new props, list retail new appox. $6000.00. Will sell for $5000.00 plus freight . I have all part numbers , invoices, details.

Similar threads

- Replies

- 21

- Views

- 2K

- Replies

- 4

- Views

- 527