Bay Pelican

Moderator Emeritus

Looking for things to check. Bay Pelican has a 27 hp Yanmar as a backup engine. Worked wonderfully until last year when I installed a separate 12 US gallon diesel tank and new Racor filter so that the engine was totally isolated from the main engine and its fuel supply.

The tank I installed was a decent brand 12 gallon tank with a top feed, typical Racor 500 series, new 5/16" fuel lines.n While the fuel line approaches the engine from below the fuel pump and thus diesel could drain down this is the same arrangement as before.

Now every time the engine sits I have to bleed air from the engine to get it started. A slight amount of air collects after the fuel pump at the location of the second bleed screw right before the injection pump.

I have tightened all fittings. I have checked the seal on the Racor. Tightened the bleed screws on the Yanmar (there are two).

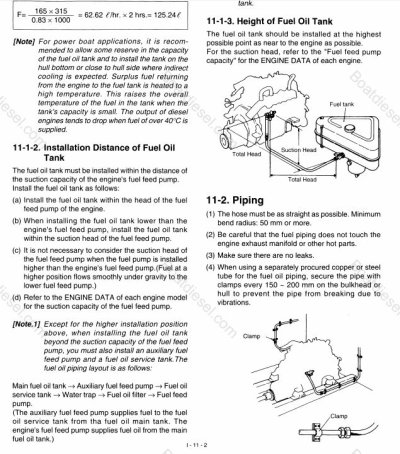

The 12 gallon tank while it is a top feed is above the level of the Yanmar's fuel pump, as is the Racor. The old tank feed was from the bottom of Bay Pelican's fuel tanks and thus there was pressure from the weight of the fuel.

My next approach is to connect the current Racor to one of Bay Pelican's bottom feed fuel tanks directly and not use the new tank and see if that changes anything. If that doesn't work I will bypass the Racor and see if it is the problem (anything is possible.)

Wondering if the Yanmar fuel system is such that there is a slow leak of air and the fuel is draining back to the tank or the Racor.

Another approach I am thinking of is raising the last 12 inches of the fuel hose above the fuel pump so that that fuel drains down and puts pressure on the fuel pump.

Any other things to check or suggestions would be appreciated.

The tank I installed was a decent brand 12 gallon tank with a top feed, typical Racor 500 series, new 5/16" fuel lines.n While the fuel line approaches the engine from below the fuel pump and thus diesel could drain down this is the same arrangement as before.

Now every time the engine sits I have to bleed air from the engine to get it started. A slight amount of air collects after the fuel pump at the location of the second bleed screw right before the injection pump.

I have tightened all fittings. I have checked the seal on the Racor. Tightened the bleed screws on the Yanmar (there are two).

The 12 gallon tank while it is a top feed is above the level of the Yanmar's fuel pump, as is the Racor. The old tank feed was from the bottom of Bay Pelican's fuel tanks and thus there was pressure from the weight of the fuel.

My next approach is to connect the current Racor to one of Bay Pelican's bottom feed fuel tanks directly and not use the new tank and see if that changes anything. If that doesn't work I will bypass the Racor and see if it is the problem (anything is possible.)

Wondering if the Yanmar fuel system is such that there is a slow leak of air and the fuel is draining back to the tank or the Racor.

Another approach I am thinking of is raising the last 12 inches of the fuel hose above the fuel pump so that that fuel drains down and puts pressure on the fuel pump.

Any other things to check or suggestions would be appreciated.