High Wire

Guru

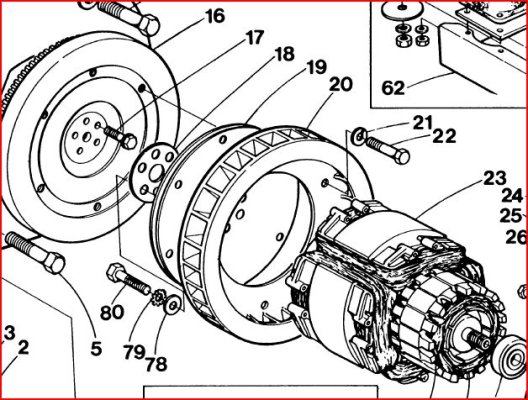

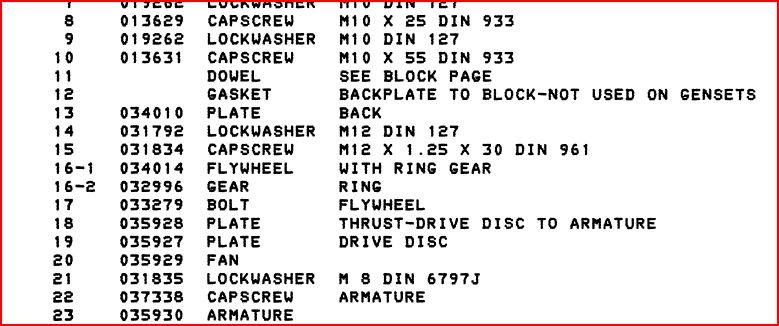

In Dec 2014, our WB 8 BTD generator (~2100 hours) tore up its thrust drive plate disc. Actually it is 2 discs Siamese'd together (#19 in pic). This plate connects the engine flywheel to the generator armature. The gen was running at light load powering the battery charger, house loads with no air cond running. The plates are made of aluminum. The aluminum plates sheared 360 degrees around the outside of the armature bolt pattern, not between the holes.

Long story short, the diesel mechanic never saw this type of part failure before (ie freeky failure). New plates were installed, the roller bearing on the end of the armature was good. Everything back together and all was well.

EXACTLY one year to a couple minutes and 20 runtime hours later, the same failure occurs.

The previous owner had some type of problem with the gen set about 6 months prior to our purchase but I have no records from that repair other than the generator was "rebuilt". Its likely that the same thing happened to him as well.

Other than this, the gen runs smooth, quiet and trouble free. It has plenty of life left.

I do not want to get into a costly troubleshooting effort for a generator this old calendar wise.

I want to take a new plate to a machine shop and make one out of steel.

Long story short, the diesel mechanic never saw this type of part failure before (ie freeky failure). New plates were installed, the roller bearing on the end of the armature was good. Everything back together and all was well.

EXACTLY one year to a couple minutes and 20 runtime hours later, the same failure occurs.

The previous owner had some type of problem with the gen set about 6 months prior to our purchase but I have no records from that repair other than the generator was "rebuilt". Its likely that the same thing happened to him as well.

Other than this, the gen runs smooth, quiet and trouble free. It has plenty of life left.

I do not want to get into a costly troubleshooting effort for a generator this old calendar wise.

I want to take a new plate to a machine shop and make one out of steel.

Attachments

Last edited: