ranger58sb

Guru

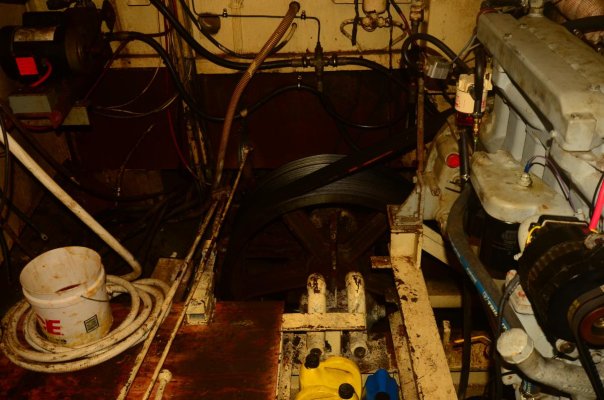

This article in Soundings mentions two boats running twin 6-71s on a single shaft:

Chesapeake T-boats, happy in retirement | Soundings Online

How are those likely connected? Some kind of combining gear system? Or...?

However accomplished, does it mean one can run on one engine when desired, two when needed? Or would it always be on both?

If complete flexibility is there, would maybe seem similar to a get-home installation, with a main and an auxiliary (or genset)? Wouldn't need both engines to be large...

??

-Chris

Chesapeake T-boats, happy in retirement | Soundings Online

How are those likely connected? Some kind of combining gear system? Or...?

However accomplished, does it mean one can run on one engine when desired, two when needed? Or would it always be on both?

If complete flexibility is there, would maybe seem similar to a get-home installation, with a main and an auxiliary (or genset)? Wouldn't need both engines to be large...

??

-Chris