You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Steam in the exhaust

- Thread starter R_p_ryan

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

R_p_ryan

Senior Member

- Joined

- Dec 11, 2014

- Messages

- 171

- Location

- USA

- Vessel Name

- Shellbourne

- Vessel Make

- 1978 Mainship 34 Perkins T6.354

Please accept my apologies for high-jacking your thread, but after reading the comments here, I was amazed at how many Perkins owners have chimed in. I am in desperate need of parts to rebuild my starboard T6-354 (X) (CCWR). I have been told that there are no parts available for the X engine. I have also been told that the pistons and connecting rods are different than those in the T6-354 (CWR) engine. Is this true?, and, if so, can you offer an alternative solution to this re-build dilemma?

Advice and Options Much Appreciated

Thank You

Capt Nemo

I'm sure we'll chime in if you start a new thread. BTW, if you're rebuilding why not just do the sleeves and rings, as I'm guessing those would be the same. I'm looking at the workshop manual, and it includes contra rotating engines. The specs for pistons, valves, rings, bearings, etc make no mention of reverse engines.

jleonard

Guru

- Joined

- Jun 25, 2008

- Messages

- 5,067

RR:

Some observations:

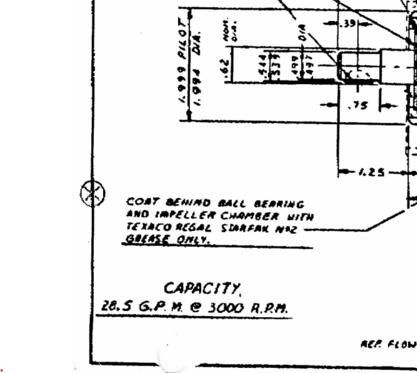

The 28.5 gpm spec that someone quoted for the Perkins seems extraordinarily high. Could he have meant 28.5 gph?

David

I quoted that number. Directly off of Sherwood's engineering drawing.

Would you like a copy?

Similar threads

- Replies

- 33

- Views

- 1K

Latest posts

-

-

-

-

Fixing boats in Exotic Places - are new boats really that bad?

- Latest: HeadMistress

-

-

-

-

-

-