Chris Foster

Senior Member

Started having a similar problem to one discussed here last fall - an RPM surge in the stbd engine every few minutes.* It also would idle 200-300 RPM high for 20-30 seconds at a time.* This is on a T6.354 Perkins.

The consensus here was a plugged filter or air leak.* Vacuum gage on the Racor showed the filter OK even after a full RPM run, so a leak seemed likely.* I plumbed in a short section of clear vinyl tubing on the fuel return, and every 30 seconds or so, a small bubble would appear.* So definitely an air leak, but seemingly a pretty tiny one.

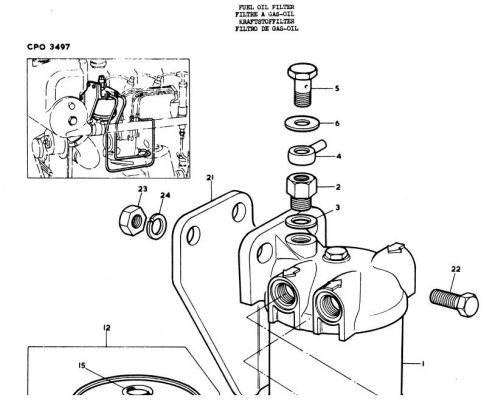

The primary filter has a fuel bleed at a high point on its inlet side*that should bleed off any small bubbles long before they get into the injection pump, so I decided to check that for obstructions while changing the primary filter.* The bleed circuit has a check valve and then a banjo bolt that feeds a collar and a bit of copper tube to the return outlet.* I pulled out the banjo bolt and blew through it - blocked solid.* What the ???* The banjo bolt was drilled axially (through the center along the axis) but not radially (where fuel would exit to the collar).*

The parts manual shows a hole there, but there was*none on the part.* A minute on the drill press changed that.* I reassembled the whole business, fired up, and nary a surge.

This is a 30+ year old engine and has presumably been this way forever.* Presumably it never leaked enough air to be a problem.* I still need to determine the leak source and fix it (likely the lift pump) before it gets worse.* Still, a minor unporting of a fuel tank shouldn't be a big problem, and surely would have been on this engine.

The banjo bolt is item 5 on the attached drawing - you can see the hole drawn on the unthreaded part of the shank.

The consensus here was a plugged filter or air leak.* Vacuum gage on the Racor showed the filter OK even after a full RPM run, so a leak seemed likely.* I plumbed in a short section of clear vinyl tubing on the fuel return, and every 30 seconds or so, a small bubble would appear.* So definitely an air leak, but seemingly a pretty tiny one.

The primary filter has a fuel bleed at a high point on its inlet side*that should bleed off any small bubbles long before they get into the injection pump, so I decided to check that for obstructions while changing the primary filter.* The bleed circuit has a check valve and then a banjo bolt that feeds a collar and a bit of copper tube to the return outlet.* I pulled out the banjo bolt and blew through it - blocked solid.* What the ???* The banjo bolt was drilled axially (through the center along the axis) but not radially (where fuel would exit to the collar).*

The parts manual shows a hole there, but there was*none on the part.* A minute on the drill press changed that.* I reassembled the whole business, fired up, and nary a surge.

This is a 30+ year old engine and has presumably been this way forever.* Presumably it never leaked enough air to be a problem.* I still need to determine the leak source and fix it (likely the lift pump) before it gets worse.* Still, a minor unporting of a fuel tank shouldn't be a big problem, and surely would have been on this engine.

The banjo bolt is item 5 on the attached drawing - you can see the hole drawn on the unthreaded part of the shank.