Obelikx

Veteran Member

- Joined

- May 19, 2012

- Messages

- 29

- Location

- Netherlands

- Vessel Name

- Obelikx

- Vessel Make

- De Klerk Kotter

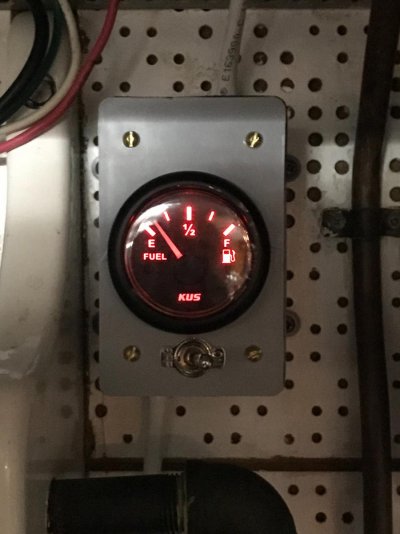

A technical question: how do you manage refilling your day tank?

A few years ago after installing a new day tank and an ultrasonic gauge, I managed to overfill the tank and flood the bilge with some diesel fuel (a mess to clean up). The reason: while in the marina the electronic of the ultrasonic unit gives a relatively rapid reading, in a seaway with the movements of the fluid surface, it takes more than a minute before you get a reading of the actual level: and this led me to overfill the tank because my reading was still sth like half full …

A lesson learned the hard way. In a seaway, I now always use a timer and keep the finger on the fuel pump switch all the time during refilling.

After spending a few hours cleaning the diesel out of every corner of my engine room, I was convinced that I would quickly work on a solution … however, as usual with an old boat many other projects got priority.

Now, its again on the agenda for 2019. So I am interested how you guys manage filling the day tank? Manually? With an alarm? Fully automatic? And which sensors do you use? (As I like being in control of the actual fuel consumption and switch between main tanks to the day tank, I am more thinking of an alarm and/ or an relais that is switched of once a certain level is reached instead of a fully automatic system).

thanks a lot for your input

A few years ago after installing a new day tank and an ultrasonic gauge, I managed to overfill the tank and flood the bilge with some diesel fuel (a mess to clean up). The reason: while in the marina the electronic of the ultrasonic unit gives a relatively rapid reading, in a seaway with the movements of the fluid surface, it takes more than a minute before you get a reading of the actual level: and this led me to overfill the tank because my reading was still sth like half full …

A lesson learned the hard way. In a seaway, I now always use a timer and keep the finger on the fuel pump switch all the time during refilling.

After spending a few hours cleaning the diesel out of every corner of my engine room, I was convinced that I would quickly work on a solution … however, as usual with an old boat many other projects got priority.

Now, its again on the agenda for 2019. So I am interested how you guys manage filling the day tank? Manually? With an alarm? Fully automatic? And which sensors do you use? (As I like being in control of the actual fuel consumption and switch between main tanks to the day tank, I am more thinking of an alarm and/ or an relais that is switched of once a certain level is reached instead of a fully automatic system).

thanks a lot for your input