The 20% figure I was given by two different prop people at 2 different occasions. I have no scientific backing for this.

But consider this: Think of a prop as a multi-tool. It will do most OK and one or two things real well. Again, I have no knowledge of the following statements, but this is what logic tell me: The boat was designed to cruise around 16 knots. It also can idle and can go WOT about 4000 to 4400 RPM's. The designer will use a prop that will serve him best at cruising speed - 16 kts. Probably 3000 to 3400 RPM. So, at a hair above idle speed - around 6Kts, where I want to be, I am at the lowest end of efficiency this engine/prop arrangement can possibly be. So not only is this the most inefficient speed, it is also the most under-loaded speed I could go. Remember, the prop is not a 'fits all speed' kinda thing.

Given this, and not knowing any better, I will take both their word for it.

Adding 1" pitch and a small cupping, I am not to concerned about popping wheelies idling out of my slip.

The cupping and added pitch will add a little more load to the engine and bring it closer to it designed load. It will still be far far away, but closer.

The logic suits me just fine and I am still very comfortable with it. Especially when I run on one engine only.

The chances of you doing your engines great harm I think is pretty small...

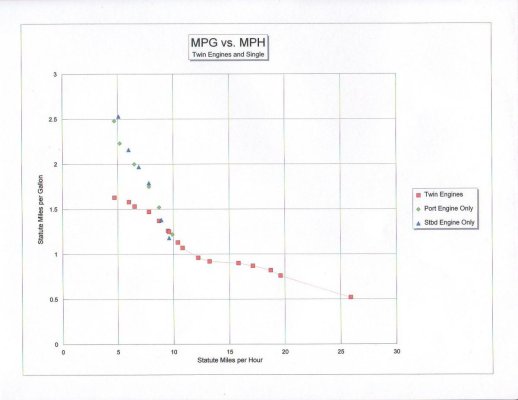

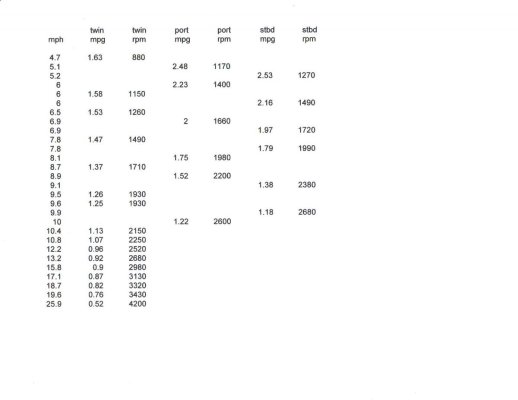

I've posted it before...but what the heck.

Finishing up my 11th year running a 26ft Shamrock with a carbed 454, and (don't remember exactly" but way bigger, overpitched, cupped, 4 bladed prop. We do this for pulling power...not speed or efficiency....

As an assistance towing boat it gets probably less care than most rec boats...but does get 200 hr oil changes with "whatever" oil is cheap.

The motor is 12 years old and get around 400 hrs on it every year. It sits for hours idling and hour upon hour at 2000-2500 rpm towing vessels 8-50 feet.

I has at least 20 hours of running with the overheat alarm going off and op temps of between 225-250...blowing coolant all the while I'm towing.

The worst 2 hrs of it's life were when I had to survive a 3 knot current, pulling a 15x40 barge in a Nor'easter. The normal top end RPM is about 4200 and that night I had it on the pin for over 2 hrs and the rpm never got above 3000...overloaded a bit?

When pulling boats off sand bars...often the motor again goes from 2000-3500 rpm in seconds until the prop is cavatating so bad and the boat shaking so much I can't read the instruments. Often the boat will slingshot rearwards into another sand bar and stop the motor dead.

I have run the boat for weeks with nothing but duct tape holding the water in the exhaust tubes and once ran it for a week or better with a pencil sized hole in the side of the water pump from sand erosion when we used to dredge slips with the boats.

The motor burns no oil, doesn't leak coolant, it has had several alternators and starters...but with exhaust hoses and pumps throwing salt water around the engine compartment for days...what the heck. Some electrical parts and a set of exhaust elbows...but the main motor and parts are 12 years old this winter.

So all you "you're gonna blow her up" guys...have at it...I know better what the average motor can take...cruising around in a pleasure boat unless the captain it a total deadhead is nothing at all like commercial service.

Somehow if Tony overprops by a couple hundred RPM and gets 5000 hrs out of his gas engines...I think he'll be happy.

And my engine is no fluke...the other Shammies in the fleet don't get quite as hard as service as my boat because they have more open water coverage...but they aren't far behind.