Steve, check out these pumps: https://www.grainger.com/product/PROCON-1-2-Stainless-Steel-Rotary-6XE90

You can get them in a number of sizes, and they are driven by a 1/3 hp 120 vac motor. The carbonator clamp attachment makes it simple to mount. Quiet, and seemingly indestructible.

On my system, one pump draws through a 30 micron Racor 1000 that I run to maintain refinery spec on bulk fuel storage. The other motor/pump is wired through a pair of Omron programable relays that allow me to set an off time separate from the on time. If I leave the boat for a month and want to refill the boiler day tank, the off time is set to 7 days and on the on time to 3 minutes and this keeps that day tank topped off. Or, if I want to polish for 3 days sitting at the dock, that is easy. The filter on this pump is a 10 micron, and I use it to transfer fuel from one tank to another.

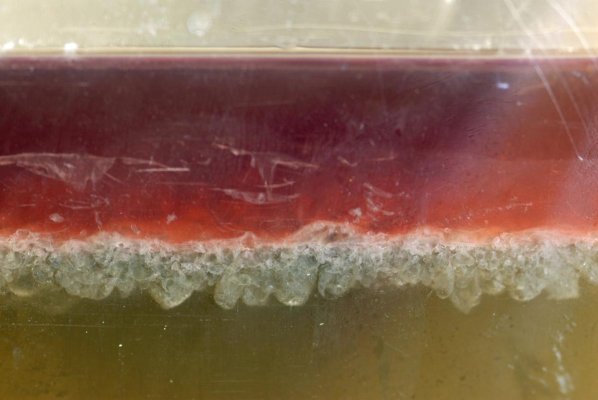

I built this system for around $1,500 in parts, not counting the hoses, my labor, or two Debug units which everyone will say are pointless, but which I had great success with in cleaning up a contaminated tank on a prior boat.

Delfin:

Interesting. I see no mention in the specs of use with fuel. It says "Pump is compatible with fire-resistant fluids, hydraulic oil, lubricants, coolants, insecticides, and soap. Can also be used in dispensers, espresso machines, sprayers, filtration and water purification processes, team-cleaning and car-washing machines, pressure boosters, atomizing/misting humidification systems, circulation systems, laboratory pumps, pilot plants, boiler feeds, textile machines, and fire jockey pumps."

There's no doubt handy, knowledgeable folks who have an understanding of ABYC standards can build there own effective and safe polishing system. Knowing you and your boat, I'm sure it's all of these things and it looks very good too.

I SAY BRING BACK OTDE at least all the bullshit was confined to one area instead of filling all the posts else wear

I SAY BRING BACK OTDE at least all the bullshit was confined to one area instead of filling all the posts else wear