BallardPilot

Member

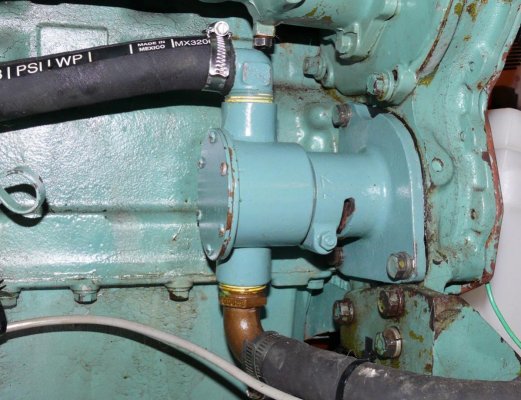

I recently did fall maintenance on my Chub, after replacing the impeller, the plate that seals in the impeller is leaking a little. I used the fiber seal, as the previous owner has good luck with those. I've heard that those seals tend to leak a bit then seal better after a few hours of running and a re-torquing.

I am curious if anyone has found a better seal or can confirm that the fiber seal will expand/seal further. I've heard guys that use grease, rubber seals, etc. What works for you Lehman experts out there?

I am curious if anyone has found a better seal or can confirm that the fiber seal will expand/seal further. I've heard guys that use grease, rubber seals, etc. What works for you Lehman experts out there?