Ben

Guru

- Joined

- Dec 10, 2007

- Messages

- 758

- Location

- US

- Vessel Name

- Silver Lining

- Vessel Make

- Heritage East 44 / Twin Perkins T6.3544

Ben:

In post #20 you mention moving on to your cooling system after the fuel issue is solved. New hoses and clean heat exchangers are a good idea, but, I would advise removing the heat exchanger and also the oil cooler and taking them to a radiator shop and let them handle the job. I have done this and the cost for both was under a $100 total. Both came back looking brand new and was worth not worrying about poking a hole in the heat exchanger while reaming.

Mike

Mike - Thanks! Excellent call.

OK On to fuel...

Called Brian at American Diesel Corp, the manufacturer of my engine.

Details:

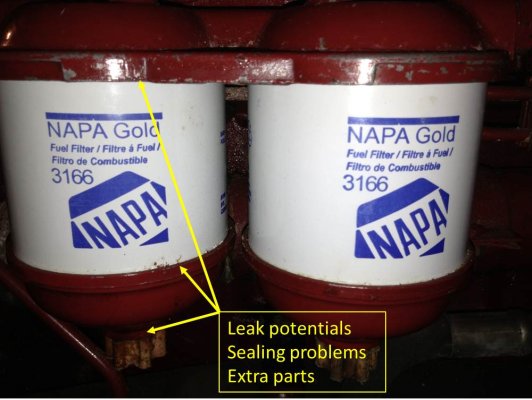

- Told him of my NAPA filter, supplied by the PO. He said this is the least recommended brand due to least reliability. Understand these are what I took off the motor initially, but will switch.

- He recommended Fram, CAV, Caterpillar, Perkins, Purolator, just not the auto-store copies.

- Asked about spin-ons. He was adamant that I would have more trouble with these. It was like I insulted his mother. I mean adamant.

- He advised me on HOW to plunge the lift pump lever, which I will do and have done after the first couple times. (Slow and steady, not fast and hyper)

- I followed the manual procedure and he agreed with my process (because it follows the manual they wrote. Imagine that).

and then found new rubber bushings for inlet and outlet lines.

and then found new rubber bushings for inlet and outlet lines.