Brooksie

Guru

- Joined

- Oct 20, 2007

- Messages

- 1,310

- Location

- USA

- Vessel Name

- Island Seeker

- Vessel Make

- Willard 36 Sedan

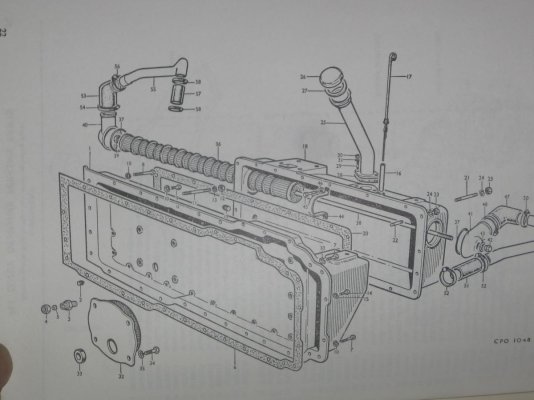

I finally decided to hoist my Perkins HT6.354 out, remove the oil pans, check the bearings & oil system and get to the cause of two problems. 1) chronic low oil pressure

2) oil runs from the tank to the crankcase while not in use giving a false low reading on the dipstick.

I used threaded rod and cross beams to raise the engine high enough to remove the oil pan, clean the bilge under, remove the main & rod bearings, oil pumps, pickups, and associated piping.

I checked all the rod bearings and they looked like new. With Plastigage they showed .002 clearance. so not the problem.

I only checked the 5 central main bearings, same as above looked new and .003 clearance.

On close examination there was a little wear on the oil pump rotor and none on the end caps. But I replaced it anyway.

I made an adapter and checked the relief valve on compressed air. It opened at 55psi consistently so that wasn't the problem.

The seal between the 2 oil pans (this is a dry sump system) was hard as a rock but in good shape. This is the only way oil can get from the tank section to the block section. It was bunaN but I replaced it with Viton which should remain soft enough to take up the expansion between the 2 sections which must be letting the oil pass while shut down.

Finally, and I'll know when I get it back together and started, I think the oil pressure problem was caused by two 11/16 ID Orings on the oil pump outlet/relief valve inlet connecting tube. They were hard as a rock, cracked in several places and flattened ID & OD. One Oring seemed to have a small piece missing but I can't be positive of that. I have replaced them with Viton rings also.

B/4 I close it back up, I will use my air adapter mentioned above it blow air into the oil system to be sure that I don't have a bad cam bearing or the #1 or #7 main bearing isn't bad or some other crazy thing that I can't see.

Final report to follow

2) oil runs from the tank to the crankcase while not in use giving a false low reading on the dipstick.

I used threaded rod and cross beams to raise the engine high enough to remove the oil pan, clean the bilge under, remove the main & rod bearings, oil pumps, pickups, and associated piping.

I checked all the rod bearings and they looked like new. With Plastigage they showed .002 clearance. so not the problem.

I only checked the 5 central main bearings, same as above looked new and .003 clearance.

On close examination there was a little wear on the oil pump rotor and none on the end caps. But I replaced it anyway.

I made an adapter and checked the relief valve on compressed air. It opened at 55psi consistently so that wasn't the problem.

The seal between the 2 oil pans (this is a dry sump system) was hard as a rock but in good shape. This is the only way oil can get from the tank section to the block section. It was bunaN but I replaced it with Viton which should remain soft enough to take up the expansion between the 2 sections which must be letting the oil pass while shut down.

Finally, and I'll know when I get it back together and started, I think the oil pressure problem was caused by two 11/16 ID Orings on the oil pump outlet/relief valve inlet connecting tube. They were hard as a rock, cracked in several places and flattened ID & OD. One Oring seemed to have a small piece missing but I can't be positive of that. I have replaced them with Viton rings also.

B/4 I close it back up, I will use my air adapter mentioned above it blow air into the oil system to be sure that I don't have a bad cam bearing or the #1 or #7 main bearing isn't bad or some other crazy thing that I can't see.

Final report to follow