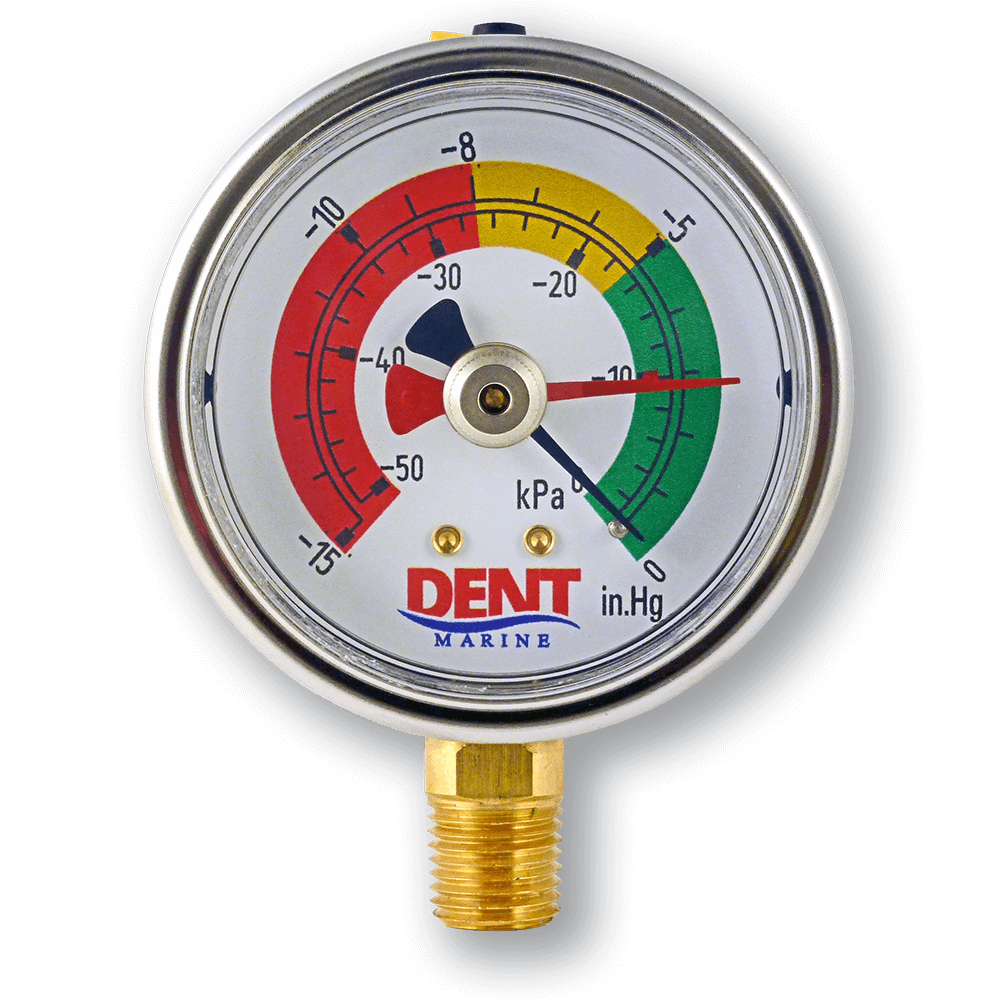

For the last couple of years I've been recommending this gauge (depicted in an earlier post), it's not cheap but it has some nice features, easy to read large face, and liquid-filled (used to be an option but I'm pretty sure it's standard now). More importantly, however, the scale is far more practical, the gauges that go all the way to a perfect vacuum of 29" are wasting much of that space, as few engines would run at those higher vacuum levels. The Dent Gauges goes from 0 to 15 (with no pressure side), covering the whole range of the gauge face. The owner of the company is an engineer with a manufacturing business, and a boat owner.

https://dentmarine.com/

Racor's own drag needle gauge works, but its scale is too broad, going to9 29", it isn't liquid filled and the drag needle reset knob lacks the necessary resistance, it can be moved if you simply brush by it with a shirt sleeve. One common fault I encounter is the drag needle is 359 degrees out of position, i.e. it is set on the wrong side of the primary black needle, which means the drag needle will never move.

Speaking of plastic, earlier in the thread someone brought up Racor's plastic bowls and flame shield. I've been to the plant where Racor filters are made, in Modesto CA. Their engineers showed me results of a flame test on Racors with and without the heat shield. While they recommend the heat shield on all Racor turbine series used afloat, the filter without the bowl shield passed the test...provided it had a metallic drain. The bowl did not burn through, but the black plastic drain did. They see the stainless shield as a belt and suspenders approach. You should have both heat shield and metallic UL Marine approved valve. Here is the article about that visit

https://stevedmarineconsulting.com/wp-content/uploads/2014/03/Racor-Very-Fine-Filtration.pdf