You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Fuel manifold

- Thread starter Soundwiz

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

Soundwiz

Veteran Member

- Joined

- Nov 26, 2012

- Messages

- 53

- Location

- USA

- Vessel Name

- Spanish Moon

- Vessel Make

- Roughwater 44' Pilot House

Baggiolini

Senior Member

A lot of choices there.

markpierce

Master and Commander

- Joined

- Sep 25, 2010

- Messages

- 12,557

- Location

- USA

- Vessel Name

- Carquinez Coot

- Vessel Make

- penultimate Seahorse Marine Coot hull #6

I don't have a valve schedule. I mentally trace the flow several times. The set-up does all the same functions as yours.

Soundwiz

Veteran Member

- Joined

- Nov 26, 2012

- Messages

- 53

- Location

- USA

- Vessel Name

- Spanish Moon

- Vessel Make

- Roughwater 44' Pilot House

I don't have a valve schedule. I mentally trace the flow several times. The set-up does all the same functions as yours.

Mark, very nice, the manifold block keeps the clutter down, this was my first attempt at this. If I ever do it again I'll keep that in mind.

FF

Guru

- Joined

- Oct 12, 2007

- Messages

- 22,552

Remember those holes in the valve handles can be used to gang the valves.

If a 3 way pair is used it can supply fuel from a tank , and return fuel to the same tank, no thinking or fuel pickup and delivery diagrams needed.

KISS

If a 3 way pair is used it can supply fuel from a tank , and return fuel to the same tank, no thinking or fuel pickup and delivery diagrams needed.

KISS

- Joined

- Mar 17, 2012

- Messages

- 4,280

- Location

- Australia

- Vessel Name

- Insequent

- Vessel Make

- Ocean Alexander 50 Mk I

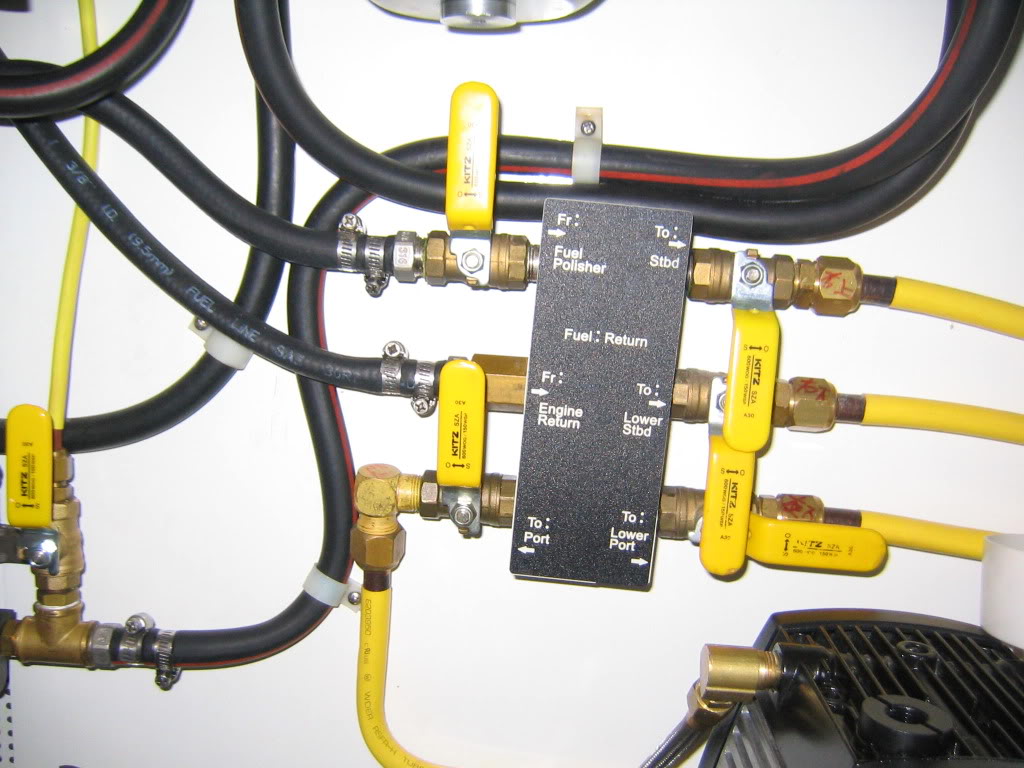

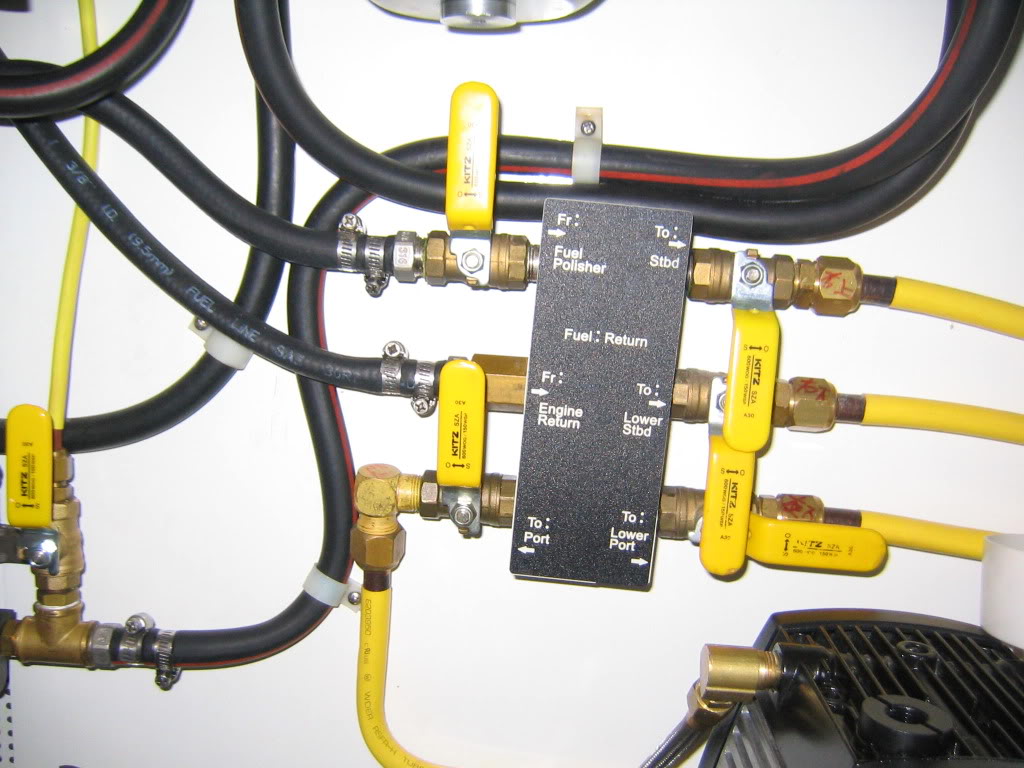

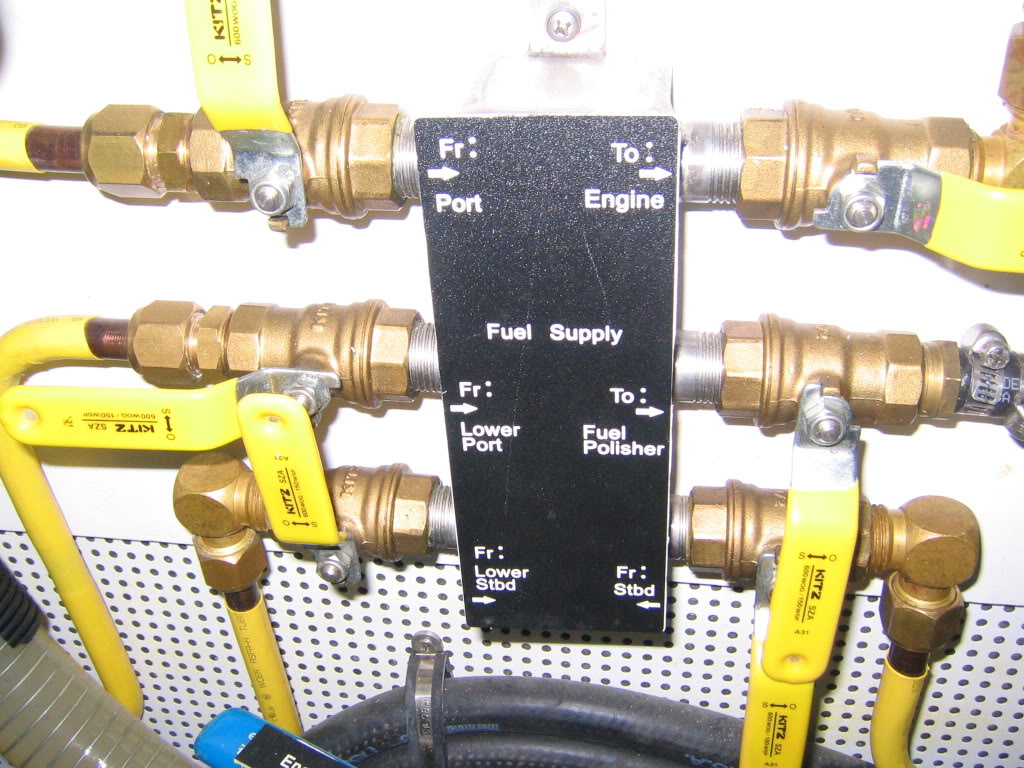

Here's my new system. Reverso liked it so much that they borrowed photos from the CoOp's blog for their own blog. I'll post the story of my fuel system refit soon. I'm waiting on some engraved labels for the manifolds an for the sight gauges to finish the job.

Reverso Pumps Blog

I have 1240 gallons in 6 tanks. The engines can draw from any tank and return to any tank. The Reverso fuel polisher has separate tank draw downs, larger diameter hose lines and can also draw from any tank and return to any tank.

The glass sight tubes for the aft tanks are shown also. They have brass rods each side of the glass tubes to protect them, but in the event of a glass breakage the lower gate valve assembly includes an internal ball that prevents high flows.

Reverso Pumps Blog

I have 1240 gallons in 6 tanks. The engines can draw from any tank and return to any tank. The Reverso fuel polisher has separate tank draw downs, larger diameter hose lines and can also draw from any tank and return to any tank.

The glass sight tubes for the aft tanks are shown also. They have brass rods each side of the glass tubes to protect them, but in the event of a glass breakage the lower gate valve assembly includes an internal ball that prevents high flows.

FF

Guru

- Joined

- Oct 12, 2007

- Messages

- 22,552

"The engines can draw from any tank and return to any tank."

This could cause the receiving tank to become overfilled.

Where does the overfill fuel go ? Out the vent? In the bilge? , to an emergency tank?

This could cause the receiving tank to become overfilled.

Where does the overfill fuel go ? Out the vent? In the bilge? , to an emergency tank?

Tom.B

Moderator Emeritus

- Joined

- Jul 30, 2009

- Messages

- 5,839

- Location

- USA

- Vessel Name

- Skinny Dippin'

- Vessel Make

- Navigator 4200 Classic

That looks familiar

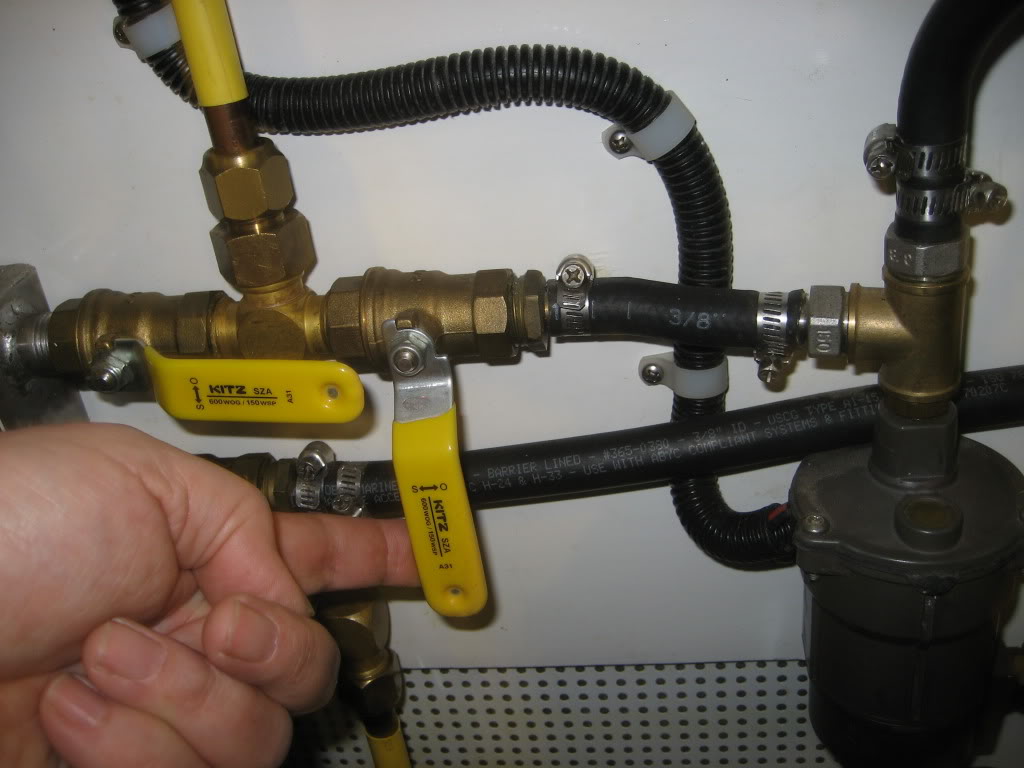

This is mine from winter 2011. Here is the thread from the build discussion: http://www.trawlerforum.com/forums/s6/fuel-system-upgrade-project-episode-ii-3761.html

Looks like the differences are: I only have a 60gph pump since that was the capacity of the filter (all transfers go thru scrubbing filter). I can scrub and transfer fuel... BUT... I have a multi-stage (1-30 micron and 1-10micron) filter system that doesn't have a "switchover" option that I see yours has. If I get a filter clog, I have to change it underway. The theory behind that was that we only use 2 GPH and do 99% inland boating. Not-to-mention I check and change filter pretty regular-like and keep my tanks clean. A catastrophic clog would be pretty rare. I've also gotten pretty good at changing them in a hurry.

Anyway, since it's installation, I added a dedicated feed to the genset and plan on adding a spigot to fill an external container with fuel for rinsing filter bodies and such. Also moved the pressure gauge to the filter closest to the engine (far left).

I kept the rig as simple as I could (thanks to a few tips from members here). I didn't want to think too hard about it and make a mistake.

This is mine from winter 2011. Here is the thread from the build discussion: http://www.trawlerforum.com/forums/s6/fuel-system-upgrade-project-episode-ii-3761.html

Looks like the differences are: I only have a 60gph pump since that was the capacity of the filter (all transfers go thru scrubbing filter). I can scrub and transfer fuel... BUT... I have a multi-stage (1-30 micron and 1-10micron) filter system that doesn't have a "switchover" option that I see yours has. If I get a filter clog, I have to change it underway. The theory behind that was that we only use 2 GPH and do 99% inland boating. Not-to-mention I check and change filter pretty regular-like and keep my tanks clean. A catastrophic clog would be pretty rare. I've also gotten pretty good at changing them in a hurry.

Anyway, since it's installation, I added a dedicated feed to the genset and plan on adding a spigot to fill an external container with fuel for rinsing filter bodies and such. Also moved the pressure gauge to the filter closest to the engine (far left).

I kept the rig as simple as I could (thanks to a few tips from members here). I didn't want to think too hard about it and make a mistake.

Attachments

Last edited:

- Joined

- Mar 17, 2012

- Messages

- 4,280

- Location

- Australia

- Vessel Name

- Insequent

- Vessel Make

- Ocean Alexander 50 Mk I

"The engines can draw from any tank and return to any tank."

This could cause the receiving tank to become overfilled.

Where does the overfill fuel go ? Out the vent? In the bilge? , to an emergency tank?

Normal operations will see engines drawing and returning from port and stbd day tanks (each 100 gal) respectively. They are the ones most vulnerable to overfilling from the polishing system ( the only way of getting fuel into them, they have no external fillers), but when full the fuel would go via the vents to the lateral tanks immediately forward of them.

When transferring fuel to specific tanks for trim or other purposes, either via engines or the polisher, then whoever is doing it has to pay attention! Like filling at the dock, the operator cant daydream or go to sleep on the job....

Interesting anecdote: when testing the capacity of the new, larger aft tanks they were filled to the top, and overflowed out the vents and onto the concrete floor of the building - not much spilled since someone saw it and kitty litter absorbed it. The vents were below the swim step and below the top of the tank! Needless to say there are new higher vents now.

The 'fill to the top' exercise was to calibrate the sight gauges and the tank tender system in 100 litre increments. From now on I know the maximum capacity, and can estimate contents of each tank both remotely and from the sight gauges. Therefore I can plan how much to safely put into any tank when at the dock.

Last edited:

Craig Schreck

Veteran Member

That looks familiar

This is mine from winter 2011. Here is the thread from the build discussion: http://www.trawlerforum.com/forums/s6/fuel-system-upgrade-project-episode-ii-3761.html

Looks like the differences are: I only have a 60gph pump since that was the capacity of the filter (all transfers go thru scrubbing filter). I can scrub and transfer fuel... BUT... I have a multi-stage (1-30 micron and 1-10micron) filter system that doesn't have a "switchover" option that I see yours has. If I get a filter clog, I have to change it underway. The theory behind that was that we only use 2 GPH and do 99% inland boating. Not-to-mention I check and change filter pretty regular-like and keep my tanks clean. A catastrophic clog would be pretty rare. I've also gotten pretty good at changing them in a hurry.

Anyway, since it's installation, I added a dedicated feed to the genset and plan on adding a spigot to fill an external container with fuel for rinsing filter bodies and such. Also moved the pressure gauge to the filter closest to the engine (far left).

I kept the rig as simple as I could (thanks to a few tips from members here). I didn't want to think too hard about it and make a mistake.

Great post

fuel polishing systems

fuel polishing systems  I play with them almost every day. Clean diesel fuel is the main way to help insure engine efficiency that the owner / operator can play a part in, When installed properly a fuel polishing system can have a huge pay back. Most of the systems we work with are high volume high flow industrial units but I have installed many on pleasure boats over the years, I dont sell any of the small name brand polishing units seen on most boats so I love the home made systems, On Diesel storage tanks it is not uncommon to collect between 1/16 to 1/8 of an inch of sludge per year of operation depending on conditions so dont confuse fuel polishing with fuel tank cleaning they are too completely different operations. Also copper is not a recomended fuel line material for Diesel its used by some for cost reduction.

I play with them almost every day. Clean diesel fuel is the main way to help insure engine efficiency that the owner / operator can play a part in, When installed properly a fuel polishing system can have a huge pay back. Most of the systems we work with are high volume high flow industrial units but I have installed many on pleasure boats over the years, I dont sell any of the small name brand polishing units seen on most boats so I love the home made systems, On Diesel storage tanks it is not uncommon to collect between 1/16 to 1/8 of an inch of sludge per year of operation depending on conditions so dont confuse fuel polishing with fuel tank cleaning they are too completely different operations. Also copper is not a recomended fuel line material for Diesel its used by some for cost reduction.FF

Guru

- Joined

- Oct 12, 2007

- Messages

- 22,552

Clean diesel fuel is the main way to help insure engine efficiency that the owner / operator can play a part in,

Sure , but the grunge in the fuel usually comes from the stuff stuck to the tank sidewalls and baffles.

The cleanest fuel can be mud after an hour of real bouncing in a dirty tank.

The only way to have clean fuel from an old tank is to either clean the tank, carry a couple of cases of filters , or bite the bullet and buy the centrifugal cleaner.

Sure , but the grunge in the fuel usually comes from the stuff stuck to the tank sidewalls and baffles.

The cleanest fuel can be mud after an hour of real bouncing in a dirty tank.

The only way to have clean fuel from an old tank is to either clean the tank, carry a couple of cases of filters , or bite the bullet and buy the centrifugal cleaner.

Craig Schreck

Veteran Member

Clean diesel fuel is the main way to help insure engine efficiency that the owner / operator can play a part in,

Sure , but the grunge in the fuel usually comes from the stuff stuck to the tank sidewalls and baffles.

The cleanest fuel can be mud after an hour of real bouncing in a dirty tank.

The only way to have clean fuel from an old tank is to either clean the tank, carry a couple of cases of filters , or bite the bullet and buy the centrifugal cleaner.

Very true, We find that the vertical tank surfaces only foul on stationary units, Its the tank bottom that collects the sludge on boats that move, We are close to Beaufort Inlet NC so on any windy day we get tow in boats with fuel problems, Most of the time its a clogged fuel pick up or line causing the problems, We did fuel tank maintenance for Tom B & Bess on Skinny Dippin last summer and he has some good pics for an example, Toms tanks had sludge up to the fuel pick up, but the fuel and the vertical surfaces were very clean, Tom installed a well designed home polishing system, but its not capable of removing the heavy sediments from the tank bottom, That's the difference in polishing vs tank cleaning, Fuel polishing @ 6 psi 150GPH / tank cleaning @ 60psi 3600GPH. Tom & Bess could have run forever with out any problems in flat seas but in foul weather they would be lucky to have just changed a filter or too, often the heavy sludge will block off the path to the filter or clog the small passages in the Racor its self. Changing out fuel filters offshore is one thing but cleaning out a fuel system offshore is another. Fuel centrifuges are good for fuel quality but wont help with the heavy sludge on the tank bottom. / Craig

FF

Guru

- Joined

- Oct 12, 2007

- Messages

- 22,552

And with a proper fuel tank, that can be easily serviced (instead of a box of fuel)

ALL these problems would never exist.

ALL these problems would never exist.

Craig Schreck

Veteran Member

And with a proper fuel tank, that can be easily serviced (instead of a box of fuel)

ALL these problems would never exist.

Now we are getting close

Tank access for maintenance on boats is the main problem, Installing inspection ports helps but there are some risks involved, Cutting large inspection ports in the baffling is another way to gain access, On really foul tanks < tanks that have been neglected > We will cut a square hole around 20 x 20 inches in the baffle and with the center plate section that we cut off, reinstall it on the diamond with bolts so we have better access. less risk than plates on the outer skin, For the most part boat fuel tanks are hard to clean compared to anything else, They consume more time per unit, there are several tanks for a small total volume of fuel & are usually in bad shape. Plus the environmental risks involved with pumping fuel @ high volume & pressure over water, If I hurt Flipper I will probably get shot

Tank access for maintenance on boats is the main problem, Installing inspection ports helps but there are some risks involved, Cutting large inspection ports in the baffling is another way to gain access, On really foul tanks < tanks that have been neglected > We will cut a square hole around 20 x 20 inches in the baffle and with the center plate section that we cut off, reinstall it on the diamond with bolts so we have better access. less risk than plates on the outer skin, For the most part boat fuel tanks are hard to clean compared to anything else, They consume more time per unit, there are several tanks for a small total volume of fuel & are usually in bad shape. Plus the environmental risks involved with pumping fuel @ high volume & pressure over water, If I hurt Flipper I will probably get shot Fuel centrifuges are good for fuel quality but wont help with the heavy sludge on the tank bottom. / Craig

Or.... you can have a fuel system in which every tank feeds via gravity from its lowest point, thus eliminating pickup tubes altogether and ensuring that every drop of fuel in a tank leaves that tank when it's emptied. Which is what the previous owner of our boat had put in when he replaced the the boat's three original tanks with five smaller tanks the year before we bought it.

And we've developed a fuel management system that ensures that fuel does not sit in any tank for very long. So far in the 14 years we've had the boat we have yet to get any dirt or water in the bottoms of the Racor bowls. Other than the staining from the fuel, the filter elements coming out look like the new elements going in.

The fact the fuel dealer in our marina has a very high rate of turnover and relativley new storage tanks helps, too.

Last edited:

SeaMoose

Senior Member

- Joined

- Oct 7, 2007

- Messages

- 360

- Vessel Name

- Sea Moose

- Vessel Make

- 1976 34' D/C Taiwanese Trawler

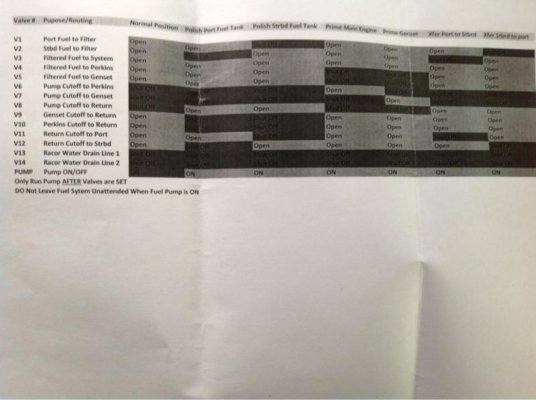

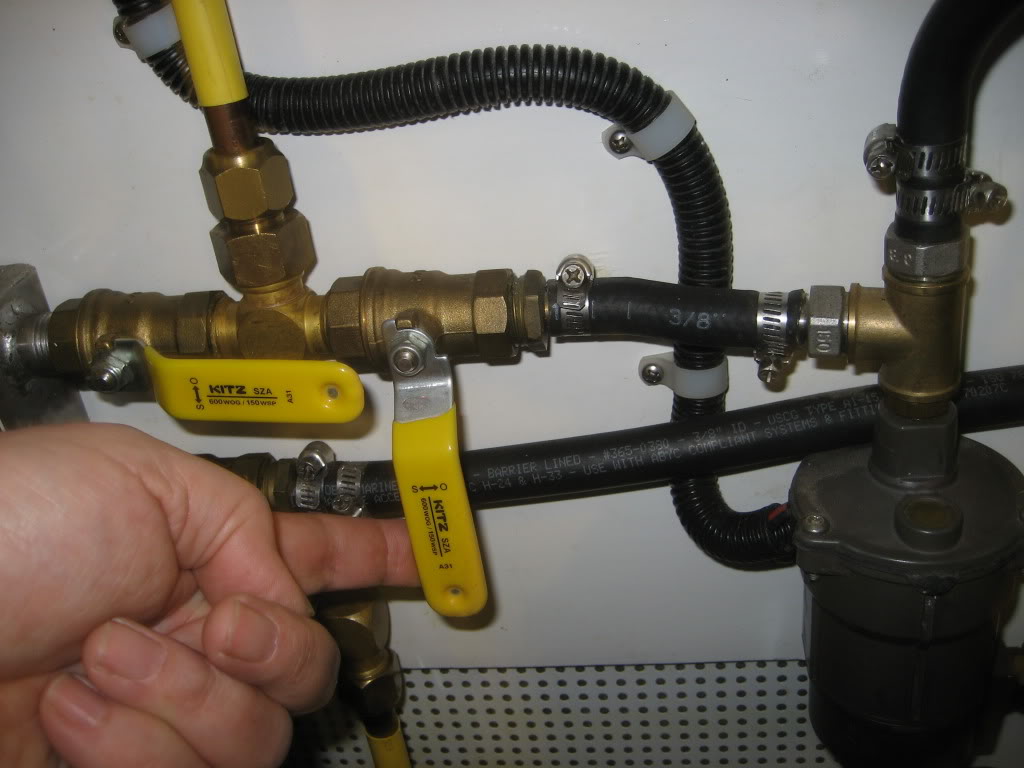

Here's my fuel manifold/polishing system:

What I want to know, Mark, is where did you get those manifolds, they are very cool. I looked and looked online for something like that and came up empty handed; mine were made at a local machine shop out of steel and weld-o-lets.

All the fittings are brass, and yes, I used AWAB hose clamps.

Only one Racor, as I didn't have room for two in the space I had, but as I have four 25 gallon tanks I can run all of the fuel in one tank through the filter twice in an hour.

What I want to know, Mark, is where did you get those manifolds, they are very cool. I looked and looked online for something like that and came up empty handed; mine were made at a local machine shop out of steel and weld-o-lets.

All the fittings are brass, and yes, I used AWAB hose clamps.

Only one Racor, as I didn't have room for two in the space I had, but as I have four 25 gallon tanks I can run all of the fuel in one tank through the filter twice in an hour.

markpierce

Master and Commander

- Joined

- Sep 25, 2010

- Messages

- 12,557

- Location

- USA

- Vessel Name

- Carquinez Coot

- Vessel Make

- penultimate Seahorse Marine Coot hull #6

What I want to know, Mark, is where did you get those manifolds, they are very cool. I looked and looked online for something like that and came up empty handed; mine were made at a local machine shop out of steel and weld-o-lets.

They came installed with the boat. You may want to inquire with Seahorse Marine. Its owner, Bill Kimley, is very helpful.

bobc

Senior Member

Caution if you have a high-pressure injection system

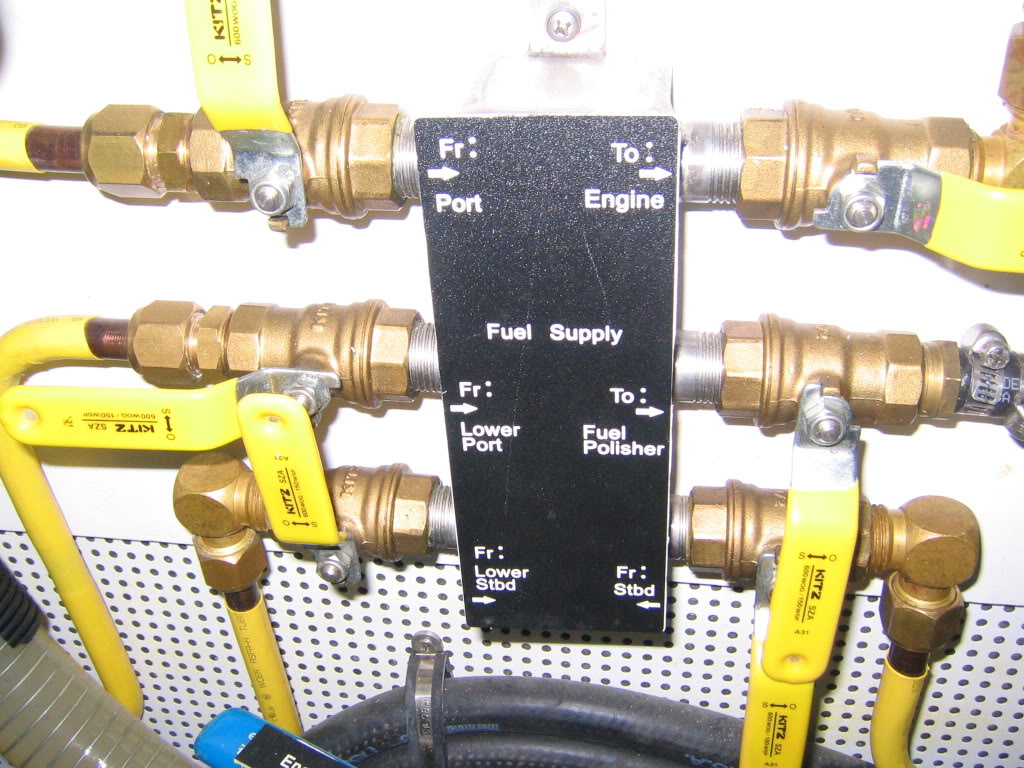

If you're prone to making mistakes, this would be a good idea. In my system I have a return manifold and a supply manifold. The valves are for port and starboard. They're shown all open in this picture. I don't run that way, I keep either the left valves open or the right valves open. The only time I'll open a port tank return with a starboard tank supply (or visa versa) is when I'm transferring fuel with the fuel polishing system.

The one thing I have to be really careful about on this system is to keep a return line open. The mechanic who installed my engine, and this fuel system told me that with a high pressure injection system, you'll immediately destroy the injectors (and pump?) if the returns are both closed.

It's flexible, but not idiot proof.

In this picture you can also see the fuel pickup is at the bottom corner of the tank.

Remember those holes in the valve handles can be used to gang the valves.

If a 3 way pair is used it can supply fuel from a tank , and return fuel to the same tank, no thinking or fuel pickup and delivery diagrams needed.

KISS

If you're prone to making mistakes, this would be a good idea. In my system I have a return manifold and a supply manifold. The valves are for port and starboard. They're shown all open in this picture. I don't run that way, I keep either the left valves open or the right valves open. The only time I'll open a port tank return with a starboard tank supply (or visa versa) is when I'm transferring fuel with the fuel polishing system.

The one thing I have to be really careful about on this system is to keep a return line open. The mechanic who installed my engine, and this fuel system told me that with a high pressure injection system, you'll immediately destroy the injectors (and pump?) if the returns are both closed.

It's flexible, but not idiot proof.

In this picture you can also see the fuel pickup is at the bottom corner of the tank.

Craig Schreck

Veteran Member

If you're prone to making mistakes, this would be a good idea. In my system I have a return manifold and a supply manifold. The valves are for port and starboard. They're shown all open in this picture. I don't run that way, I keep either the left valves open or the right valves open. The only time I'll open a port tank return with a starboard tank supply (or visa versa) is when I'm transferring fuel with the fuel polishing system.

The one thing I have to be really careful about on this system is to keep a return line open. The mechanic who installed my engine, and this fuel system told me that with a high pressure injection system, you'll immediately destroy the injectors (and pump?) if the returns are both closed.

It's flexible, but not idiot proof.

In this picture you can also see the fuel pickup is at the bottom corner of the tank.

Nice clean set up, easy to understand and operate

The fuel feed valve @ the lower corner of the fuel tank is installed very low in the tank < it looks like its lower than most > but I would guess its still 1 1/2 inches off the tank bottom, We just serviced a 300 gal tank with a very similar set up with a racor twin 900 polishing system, here is a picture of what came out of the tank,

The fuel feed valve @ the lower corner of the fuel tank is installed very low in the tank < it looks like its lower than most > but I would guess its still 1 1/2 inches off the tank bottom, We just serviced a 300 gal tank with a very similar set up with a racor twin 900 polishing system, here is a picture of what came out of the tank,Attachments

bobc

Senior Member

Nice clean set up, easy to understand and operateThe fuel feed valve @ the lower corner of the fuel tank is installed very low in the tank < it looks like its lower than most > but I would guess its still 1 1/2 inches off the tank bottom, We just serviced a 300 gal tank with a very similar set up with a racor twin 900 polishing system, here is a picture of what came out of the tank,

I was concerned about that problem, but now believe that my tanks are reasonably clean. The return is at the top of the tank and on the other end. When the tanks were less than half full, I emptied one into the other and then added back in a very small amount of fuel, just enough to keep the polishing pump primed. The fuel would drop from the top of the tank to the bottom with some velocity, and then stream down to the other end. I figured that would knock something loose, but it didn't. Other than a couple of specs of gunk, the fuel came out clean.

Craig Schreck

Veteran Member

I was concerned about that problem, but now believe that my tanks are reasonably clean. The return is at the top of the tank and on the other end. When the tanks were less than half full, I emptied one into the other and then added back in a very small amount of fuel, just enough to keep the polishing pump primed. The fuel would drop from the top of the tank to the bottom with some velocity, and then stream down to the other end. I figured that would knock something loose, but it didn't. Other than a couple of specs of gunk, the fuel came out clean.

The boat we serviced in the picture was in the process of a twin Diesel re power, The owner had run his fuel polisher often and his fuel was spotless when we pumped the 300 gals into our truck, The outfit doing the re power recommended to the owner to clean his tanks @ this point due to a high pressure common rail system with the new diesels, We had real poor tank access thru a fuel sender and we were not really expecting that much sludge do to the polisher and the above average polisher installation and the fact the owner said he never had any fuel problems in the past, We pulled fuel from his low point valve @ the polisher input and snaked a 1 inch wand thru the open fuel sender and pressure sprayed the best we could, The tank builder did not recommend we install a inspection plate due to to the wall thickness of the tank skin, the tank had 3 sections and we spent 1 hr in each section snaking past the baffles, This is not the best way to clean a fuel tank but some times that all you can do with out pulling the tank or cutting up the boat, The boat was on the hard & I really cranked up the fuel pressure for this tank, I took the picture because the owner was not there for the cleaning and was concerned about waisting money for the service, He has now scheduled another tank cleaning @ the next haul out. I find on most fuel related engine brake downs the owners felt the tanks were clean enough for normal operation and were surprised @ the volume of sludge we removed.