albertldee

Member

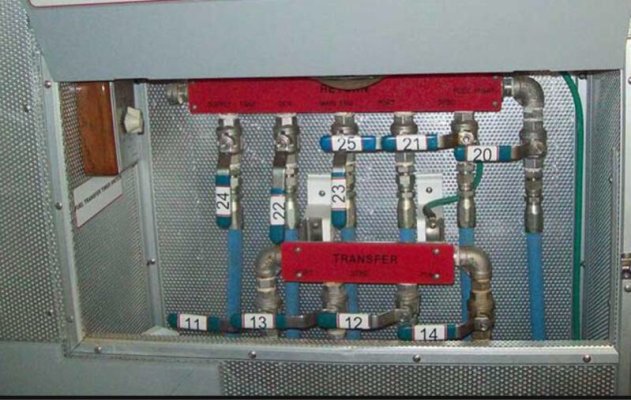

hi don't know if there is any experience fuel manifold specialist could help me design a fuel manifold material is not a problem just want to design something simple

this is what I have

2 tank AFT & FWD each tank have 1 feed only

2 pump AC and DC

what I would like to do is to have the AC pump suck and transfer to either tank

Likewise the DC pump to suck and transfer to either Tank

if I get a drawing I can follow the instruction

thanks in advice busting my brains here trying to figure it out and make it simple

this is what I have

2 tank AFT & FWD each tank have 1 feed only

2 pump AC and DC

what I would like to do is to have the AC pump suck and transfer to either tank

Likewise the DC pump to suck and transfer to either Tank

if I get a drawing I can follow the instruction

thanks in advice busting my brains here trying to figure it out and make it simple