Shoalwaters

Guru

- Joined

- Feb 24, 2008

- Messages

- 681

- Location

- St. Lucia, West Indies

- Vessel Name

- "Dragon Lady"

- Vessel Make

- DeFever 41

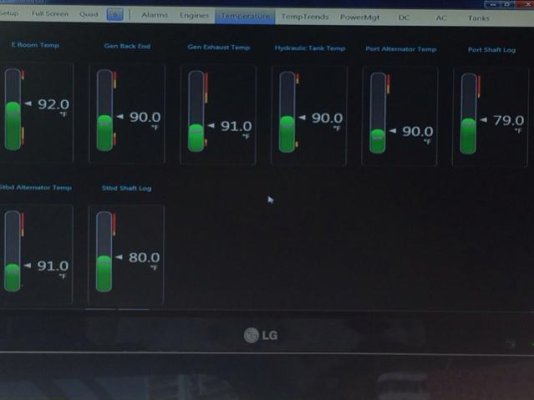

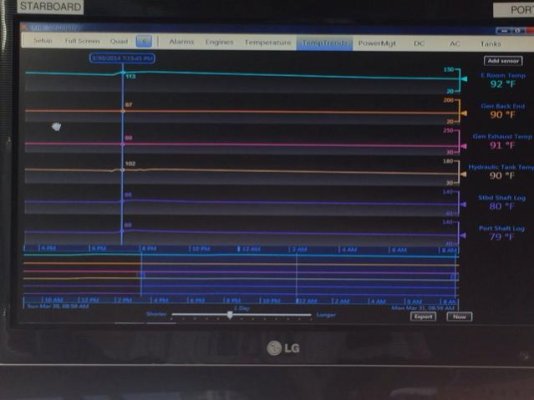

I want to fit gauges and/or alarms that will tell me if a mixing elbow is getting too hot. I am particularly concerned about the generator exhaust as it has a pretty blue silicone elbow just downstream of the seawater injection point (pic). Do you have such a monitoring system, and if so how does it perform? I seem to remember posts about using oven thermometers with remote gauges - any good?