You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Engine won't shut down

- Thread starter Pokey2

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

bobofthenorth

Guru

- Joined

- Oct 18, 2009

- Messages

- 570

- Location

- Canada

- Vessel Name

- Gray Hawk

- Vessel Make

- Defever 43 Offshore Cruiser

That's gonna be a real stretch without at least a bit of information - like at a bare minimum the engine(s) in question.

Edelweiss

Guru

Need more information, but if it is diesel, you should have a shutdown solenoid somewhere around the pump. When you push the button you activate the solenoid which pulls a lever on the injection pump that shut the fuel off and stops the engine. You can usually pull the lever manually to stop the engine, until you figure out why it's not activating when you push the button.

rochepoint

Guru

- Joined

- Apr 4, 2009

- Messages

- 1,747

- Location

- Sidney BC, Canada

- Vessel Name

- Roche Point

- Vessel Make

- 1985 Cheer Men PT38 Sedan

Is the stop button an electrical operation? Could be bad contacts in the switch or connections to the solenoid.

psneeld

Guru

there are two stop buttons and neither one works. I'll check the "shutdown solenoid" connections. I didn't know there was a manual shut off. thanks guys.

You can operate it by hand...it's right on the injector pump.

But the electric solenoid should operate it too. Just jump right at the solenoid to see if it is operating....then you can bactrack to the buttons.

Fotoman

Guru

- Joined

- Nov 12, 2009

- Messages

- 649

Had the same problem last year on same engine. Turned out to be a rusted contact on the solenoid. Cut the wire and put a new terminal and it has been working flawlessly ever since.

Slowboat 37

Senior Member

- Joined

- Aug 29, 2010

- Messages

- 191

I had the same problem last year on the ford 120. the solenoid was working just fine but the little set screw that holds on to the ss wire from the solenoid was loose and the wire slid through instead of pulling the fuel shut off lever.

FF

Guru

- Joined

- Oct 12, 2007

- Messages

- 22,552

sounds like a simple fix. i like that. thanks

Instead of a simple fix , how about a simple upgrade?

Cable , is simple and doesnt die each winter.

The loads to STOP are very low so a bronze choke cable will do,

or an outboard style cable is even more robust if the run is long.

When you switch over to Murphy Gauges . the auto secure feature will be a snap to install.

FF

Instead of a simple fix , how about a simple upgrade?

Cable , is simple and doesnt die each winter.

The loads to STOP are very low so a bronze choke cable will do,

or an outboard style cable is even more robust if the run is long.

When you switch over to Murphy Gauges . the auto secure feature will be a snap to install.

FF

Pokey2

Veteran Member

Thats what it was. A loose corroded conection . This is my first diesel powered boat, and one lesson learned.

A friend of mine has a old Dodge diesel with the cable shut down. He also said I should switch it over to cable. Not sure if I could do it from the fly bridge, but I might do it as a backup

Thanks

Clay

A friend of mine has a old Dodge diesel with the cable shut down. He also said I should switch it over to cable. Not sure if I could do it from the fly bridge, but I might do it as a backup

Thanks

Clay

I think you'll find the electrical shut down to be pretty reliable as long as the connections are in good shape so I wouldn't go to a lot of trouble to run a manual cable to the helm.

You could use a cable and just mount it in the engine room somewhere for emergencies. Make sure it doesn't interfere with the electrical shut down

You could use a cable and just mount it in the engine room somewhere for emergencies. Make sure it doesn't interfere with the electrical shut down

Started the engine for the first time this season and it wouldn't shut down when I pushed the stop buttons. What do I need to look at.

I'm assuming you eventually got it shut down without running the tanks dry so how did you do it?

I haven't found my solenoid or lever so my plan is to block the air intake if I have to. It's not safe to be fooling around on that side of my engine with it running.

Last edited:

bobofthenorth

Guru

- Joined

- Oct 18, 2009

- Messages

- 570

- Location

- Canada

- Vessel Name

- Gray Hawk

- Vessel Make

- Defever 43 Offshore Cruiser

I pulled the air filter off and blocked the intake. And i had to be careful.

That's good thinking but unnecessary. Get someone to show you where the shutdown is and try using it manually from the engine room. If you've got your button working again you can figure out yourself where the shutdown solenoid is and from there figure out how to do it manually. It isn't rocket surgery.

And rigging a manual shutdown cable is totally unnecessary. This is a very simple system with a very small number of failure points. Just learn how it works.

markpierce

Master and Commander

- Joined

- Sep 25, 2010

- Messages

- 12,557

- Location

- USA

- Vessel Name

- Carquinez Coot

- Vessel Make

- penultimate Seahorse Marine Coot hull #6

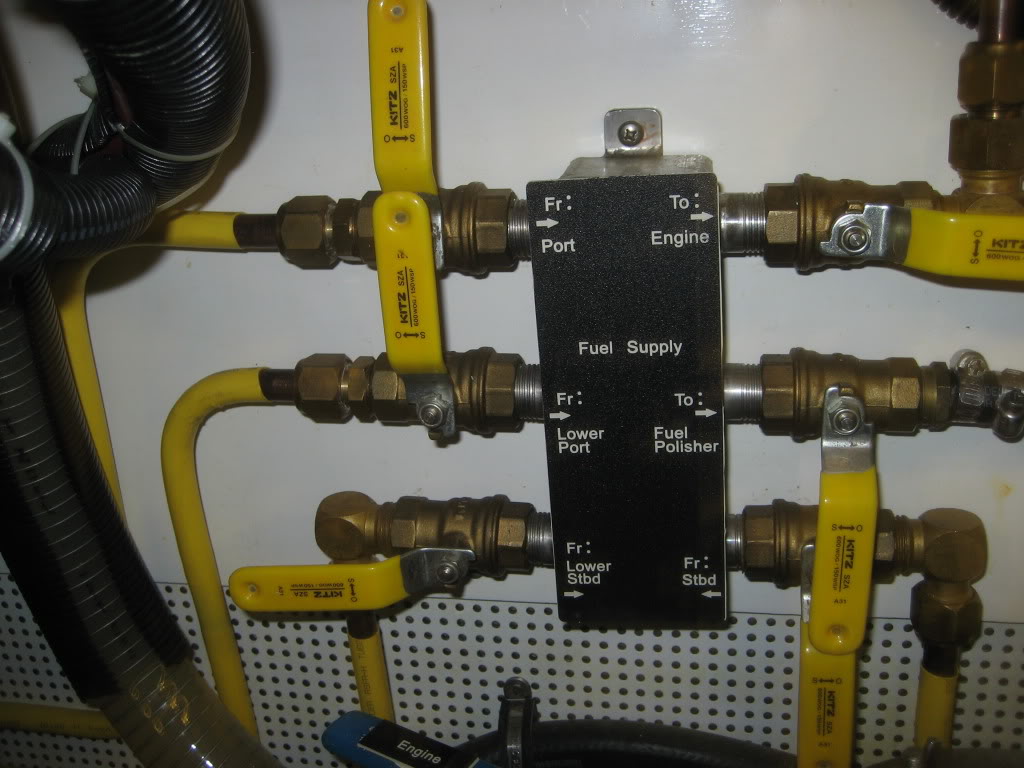

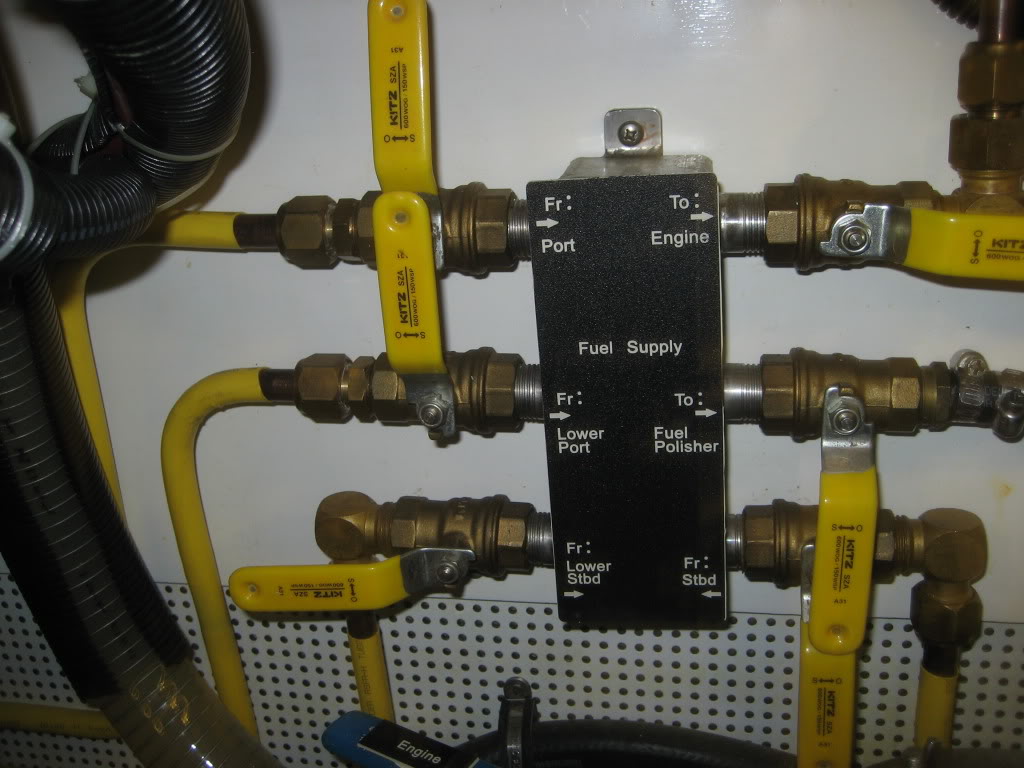

My first thought would be to shut off the fuel (close valve "To: Engine").

Last edited:

Pineapple Girl

Moderator Emeritus

- Joined

- Jun 7, 2010

- Messages

- 2,170

- Location

- USA

- Vessel Name

- Pineapple Girl 3

- Vessel Make

- Silverton 38c

My first thought would be to shut off the fuel (close valve "To: Engine").

Wouldn't that mean bleeding the fuel line when you want to start the engine again? Sounds like a royal PITA.

markpierce

Master and Commander

- Joined

- Sep 25, 2010

- Messages

- 12,557

- Location

- USA

- Vessel Name

- Carquinez Coot

- Vessel Make

- penultimate Seahorse Marine Coot hull #6

Wouldn't that mean bleeding the fuel line when you want to start the engine again? Sounds like a royal PITA.

The turn of a couple of valves allows the fuel-polishing pump to prime the engine.

Pineapple Girl

Moderator Emeritus

- Joined

- Jun 7, 2010

- Messages

- 2,170

- Location

- USA

- Vessel Name

- Pineapple Girl 3

- Vessel Make

- Silverton 38c

The turn of a couple of valves allows the fuel-polishing pump to prime the engine.

LOL yeah on YOUR boat. ok so that is your emergenct shut off, but for the rest of us, not so much...

bobofthenorth

Guru

- Joined

- Oct 18, 2009

- Messages

- 570

- Location

- Canada

- Vessel Name

- Gray Hawk

- Vessel Make

- Defever 43 Offshore Cruiser

Clamping off the air intake will stop it a lot faster than letting it run itself out of fuel. And with a lot less potential headache getting it running again.

markpierce

Master and Commander

- Joined

- Sep 25, 2010

- Messages

- 12,557

- Location

- USA

- Vessel Name

- Carquinez Coot

- Vessel Make

- penultimate Seahorse Marine Coot hull #6

I don't like the possibility of touching a hot engine.

In my case, the air filter/intake is on a pipe directly atop the engine so there is no "clamping" possible.

In my case, the air filter/intake is on a pipe directly atop the engine so there is no "clamping" possible.

- Joined

- Apr 15, 2008

- Messages

- 13,731

- Location

- California Delta

- Vessel Name

- FlyWright

- Vessel Make

- 1977 Marshall Californian 34 LRC

Mark, if you were to wrap a towel or a strip of cardboard around that air filter, I bet she'd stop pretty quickly.

I had an intermittent shut down solenoid a couple of years ago. I replaced the solenoid and I adjusted the cable at the bellcrank and thought I had it fixed, but I couldn't get full power while underway to the SF Bay. Once I relaxed the cable, the engine ran fine, but I couldn't activate the electric shut down. I rigged a length of poly cord from the bellcrank, under the floor joists and out the forward ER door. To shut down, I'd pull the string. It got me to and from the Bay area until I could fix it properly.

It turned out to be a bad wire to the solenoid. Once I replaced that wire, all was well. Now I have a spare solenoid.

I had an intermittent shut down solenoid a couple of years ago. I replaced the solenoid and I adjusted the cable at the bellcrank and thought I had it fixed, but I couldn't get full power while underway to the SF Bay. Once I relaxed the cable, the engine ran fine, but I couldn't activate the electric shut down. I rigged a length of poly cord from the bellcrank, under the floor joists and out the forward ER door. To shut down, I'd pull the string. It got me to and from the Bay area until I could fix it properly.

It turned out to be a bad wire to the solenoid. Once I replaced that wire, all was well. Now I have a spare solenoid.

markpierce

Master and Commander

- Joined

- Sep 25, 2010

- Messages

- 12,557

- Location

- USA

- Vessel Name

- Carquinez Coot

- Vessel Make

- penultimate Seahorse Marine Coot hull #6

Al, that raises a question in my mind. When I push the "off" button on the control panel, how does that stop the diesel engine? Does the solenoid cut off the fuel, cut off the air, eliminate compression, or what?

- Joined

- Apr 15, 2008

- Messages

- 13,731

- Location

- California Delta

- Vessel Name

- FlyWright

- Vessel Make

- 1977 Marshall Californian 34 LRC

I don't know about your John Deere, but my Perkins has a fuel shut off on the high pressure fuel pump that cuts off fuel near the point of delivery. The fuel lines leading into the pump remain fully charged.

You can climb down there without the engine running, but with the key in the ON position, then ask Perla to activate the stop button and see what happens. I suspect yours is similar. I think it's a pretty standard diesel practice.

You can climb down there without the engine running, but with the key in the ON position, then ask Perla to activate the stop button and see what happens. I suspect yours is similar. I think it's a pretty standard diesel practice.

...........

You can climb down there without the engine running, but with the key in the ON position, then ask Perla to activate the stop button and see what happens. I suspect yours is similar. I think it's a pretty standard diesel practice.

That's what I should do. I thought of it the other day but didn't feel like crawling around.

I don't like the possibility of touching a hot engine.

In my case, the air filter/intake is on a pipe directly atop the engine so there is no "clamping" possible.

It's important that whatever you do, nothing can get sucked into the engine. That will stop it, but probably at great cost.

The suggestion of wrapping a towel around the filter would probably work and is something I hadn't thought of.

My plan was to remove the filter and place a piece of wood over the intake. A rag or towel here would be a poor choice.

BruceK

Moderator Emeritus

- Joined

- Oct 31, 2011

- Messages

- 13,347

- Vessel Name

- Sojourn

- Vessel Make

- Integrity 386

Hi Markpierce,

What an immaculate valve/piping set up your pics demonstrate. An example to us all.

Glad to see you reclaimed your title post revamp. I seem to have lost my avatar,must be there somewhere,maybe behind the bilge pump......

BruceK

What an immaculate valve/piping set up your pics demonstrate. An example to us all.

Glad to see you reclaimed your title post revamp. I seem to have lost my avatar,must be there somewhere,maybe behind the bilge pump......

BruceK

bobofthenorth

Guru

- Joined

- Oct 18, 2009

- Messages

- 570

- Location

- Canada

- Vessel Name

- Gray Hawk

- Vessel Make

- Defever 43 Offshore Cruiser

Mark I expect your engine is common rail electronically injected. In that case the shutdown will simply turn the injectors off.

Similar threads

- Replies

- 16

- Views

- 1K