All

I have had a new riser manufactured for my new engine install. My question is while it comes with a blanket the connection flanges are not covered is this a issue. How would they best be insulated if it's important.

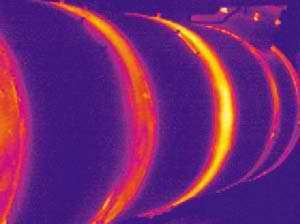

See attached pictures

It is important. Any portion of the exhaust, wet or dry, that can be touched by a person, or come into contact with any part of the vessel, overhead, timber, insulation etc, should not, according to ABYC Standards (I realize you are in Australia), exceed 200F. This holds true for not only the dry pipe but support brackets as well. I often find exhaust systems that are too hot, and especially the brackets, which are typically welded directly to the dry pipe.

The Standard...

"P-1.5.10 Protective guards, jacketing, or covers shall be provided wherever persons or gear might come in contact

with the exhaust system where the temperature exceeds 200°F (93°C).

NOTE: Engine maintenance or engine repair may make the temporary removal of this protection necessary."

My preference where insulation is concerned is for a fitted, laced on blanket for two reasons. One, it can be easily removed for inspection and repair. Two, the tape/wrap material is porous, it will absorb fuel, oil and coolant, all of which can lead to a fire (I've personally seen coolant spilled on a running, hot exhaust wrap ignite). The outer cover of most blankets is designed to not absorb liquid.

Additionally, support for the exhaust riser is critically important, the less weight that's hung from the turbo flange, and the less leverage it imparts, the better, it varies from engine manufacturer to engine manufacturer, some say zero weight, some say no more than the weight of the turbo, others specify an exact weight.