Tom.B

Moderator Emeritus

- Joined

- Jul 30, 2009

- Messages

- 5,839

- Location

- USA

- Vessel Name

- Skinny Dippin'

- Vessel Make

- Navigator 4200 Classic

After being on the hard for 3+ months, we developed a vibration in the boat. Bess noticed it first and I wrote her off as crazy since we had not been on the boat in a while and she had just lost her Mojo (and to her affinity for things that vibrate  ). Well, last weekend when I was running the motor up to temp in the slip, I had a chance to take a look at the prop shaft (and it was making a funny noise). When I looked at the stuffing box, it was wobbling around about a 1/2" each direction. That, we then knew, was the source of Bess' mystery vibration. (apologies followed

). Well, last weekend when I was running the motor up to temp in the slip, I had a chance to take a look at the prop shaft (and it was making a funny noise). When I looked at the stuffing box, it was wobbling around about a 1/2" each direction. That, we then knew, was the source of Bess' mystery vibration. (apologies followed  )

)

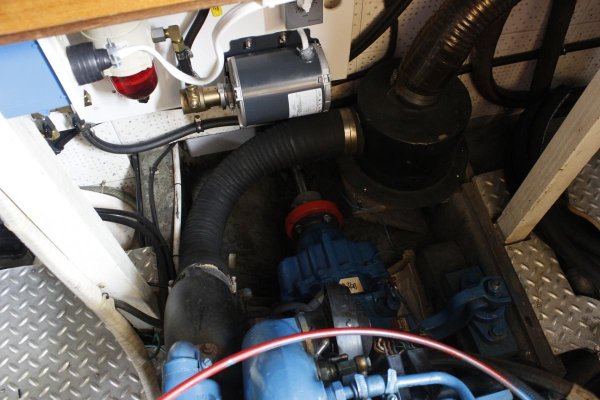

Since I was not 100% sure what was going on, we got a professional from the local boat yard to come have a look. Turns out that the Drive Saver - that red urethane disc between the transmission output and the shaft collar, had slipped off of center. Primarily due to the previous owner's use of flat washers between disc and plates.

The tech mentioned that he prefers NOT to use Drive Savers. Most notably because we are a single screw with a protected prop. "They cause more problems than they fix.", he said. The validity of that is a bit suspect because, as a tech, he only sees the BAD things that happen and may not see all the props and/or transmissions saved by them. Anyway, I am getting off the point.

After he removed the washers and reset the Drive Saver in place, all seemed somewhat back to normal. And like all things boating, good news always comes at a price. The shaft still had a slight wobble to it. He broke out the dial gauge and we do, indeed, have a bent shaft. Withing the part of the shaft he could get to, we are out by .012". Spec calls for .010" as a max, so we are just barely outside of that, but we can't see the entire shaft and could be way off down the tunnel. He has recommended that it CAN wait a little while, but we need to do it in the Fall at the latest. Considering that our 2" drop Velvet drive is no longer made, but can be rebuilt, we will probably do it mid-summer before the shaft start destroying the transmission beyond repair.

So I guess you are wondering what my question is? Well, since we will be ordering a new shaft, should we plan on replacing or removing the Drive Saver? I don't know. The little voice says to use it, but at $500 to replace, that seems like a lot for hunk of polyurethane that a 15-year marine mechanic doesn't recommend.

Tom-

)

)Since I was not 100% sure what was going on, we got a professional from the local boat yard to come have a look. Turns out that the Drive Saver - that red urethane disc between the transmission output and the shaft collar, had slipped off of center. Primarily due to the previous owner's use of flat washers between disc and plates.

The tech mentioned that he prefers NOT to use Drive Savers. Most notably because we are a single screw with a protected prop. "They cause more problems than they fix.", he said. The validity of that is a bit suspect because, as a tech, he only sees the BAD things that happen and may not see all the props and/or transmissions saved by them. Anyway, I am getting off the point.

After he removed the washers and reset the Drive Saver in place, all seemed somewhat back to normal. And like all things boating, good news always comes at a price. The shaft still had a slight wobble to it. He broke out the dial gauge and we do, indeed, have a bent shaft. Withing the part of the shaft he could get to, we are out by .012". Spec calls for .010" as a max, so we are just barely outside of that, but we can't see the entire shaft and could be way off down the tunnel. He has recommended that it CAN wait a little while, but we need to do it in the Fall at the latest. Considering that our 2" drop Velvet drive is no longer made, but can be rebuilt, we will probably do it mid-summer before the shaft start destroying the transmission beyond repair.

So I guess you are wondering what my question is? Well, since we will be ordering a new shaft, should we plan on replacing or removing the Drive Saver? I don't know. The little voice says to use it, but at $500 to replace, that seems like a lot for hunk of polyurethane that a 15-year marine mechanic doesn't recommend.

Tom-