Brooksie

Guru

- Joined

- Oct 20, 2007

- Messages

- 1,310

- Location

- USA

- Vessel Name

- Island Seeker

- Vessel Make

- Willard 36 Sedan

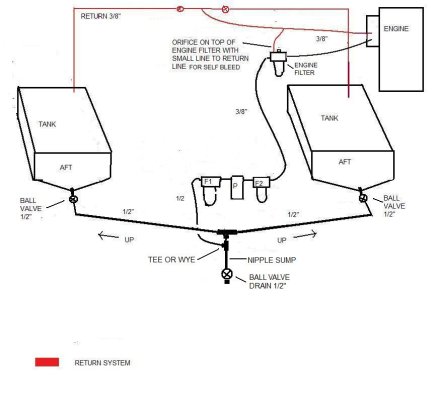

Diesel tanks usually have their draw offs in the form of a dip tube / pipe which enters through the top of the tank and goes to within 1" of the bottom. This is the recommended way I guess (required way for gasoline)

However when I replaced my tank 10 years ago, I put the draw valve at the lowest point on the theory that I wanted the sludge/water in a prefilter not caked on the bottom of the tank as happened with the old tank. I have never had a problem in the 10 years since this was done.

I need to have the tanks cleaned in my Willard and I am thinking of repiping them in the same way afterwards.

What say you all?

However when I replaced my tank 10 years ago, I put the draw valve at the lowest point on the theory that I wanted the sludge/water in a prefilter not caked on the bottom of the tank as happened with the old tank. I have never had a problem in the 10 years since this was done.

I need to have the tanks cleaned in my Willard and I am thinking of repiping them in the same way afterwards.

What say you all?