You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

bow thrusters

- Thread starter joker73

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

johnma

Guru

I have a 7 hp Sidepower on my 2003 Mainship 390. It has 3 bladed props. They now make them with 4 blade that are supposed to be stronger and quieter. Boat weighs about 27000 loaded and 7 hp works quite well

John

John

I think the Sidepower is the best on the market. Consider going with a 24volt unit with two batteries and a series parallel switch. More power, less current draw, longer run time.

You can buy a series/parallel switch from any of the marine outfits for $1k plus or buy one from a farm equipment outfit for around $200.00

You can buy a series/parallel switch from any of the marine outfits for $1k plus or buy one from a farm equipment outfit for around $200.00

Northern Spy

Guru

- Joined

- Feb 5, 2012

- Messages

- 4,075

- Location

- Canada

- Vessel Name

- Northern Spy

- Vessel Make

- Nordic Tug 26

I installed a sidepower on my boat. If nothing else go to the sidepower or imtra website and read up on installation. I read all of the manufacturers installation instructions and sidepowers were by far the best. They explained the why as much as the how. Good learning.

PS: I found it helpful to read it with a Norwegian accent.

PS: I found it helpful to read it with a Norwegian accent.

Codger2

Guru

- Joined

- Oct 11, 2007

- Messages

- 6,691

- Location

- US

- Vessel Name

- Circuit Breaker

- Vessel Make

- 2021..22' Duffy Cuddy cabin

IMO that would be a great choice for the 38 MT.I have a 7 hp Sidepower on my 2003 Mainship 390. It has 3 bladed props. They now make them with 4 blade that are supposed to be stronger and quieter.

- Joined

- Mar 17, 2012

- Messages

- 4,278

- Location

- Australia

- Vessel Name

- Insequent

- Vessel Make

- Ocean Alexander 50 Mk I

Yes, 7 HP should be a good size for the OP. I went for Lewmar's largest 12V unit, 8 HP. But were I doing it again I would do as Boatpoker suggests and go for a 24 V unit, a couple of sizes up. The Lewmar is giving good service, but in strong winds or currents it isnt large enough for my boat. Sidepower would be my first choice too.

healhustler

Guru

- Joined

- Oct 2, 2009

- Messages

- 5,198

- Location

- USA

- Vessel Name

- Bucky

- Vessel Make

- Krogen Manatee 36 North Sea

I've got a 5HP Lewmar on my 25,000 lb. Manatee and it is marginal at best. Another friend's Manatee has a later model 7 HP Sidepower and it kicks "A". Let me add that I have about a 20 ft. run of cable to the house batteries that power the unit, and that hasn't helped. Part of the plan is to install a good starter battery under the berth within a couple of feet of the thruster to give it some instant kick.

rjtrane

Senior Member

- Joined

- Apr 8, 2013

- Messages

- 268

- Location

- USA

- Vessel Name

- Sunshine

- Vessel Make

- Island Pilot DSe 12m Hybrid

If budget allows:

1. Buy bigger.

2. Use higher voltage.

3. Variable speed/continuous use.

Most builders install thrusters that work fine with up to 15 knots wind or so and for about 60 seconds or so. Bigger and longer running are better - especially when you need it most!

1. Buy bigger.

2. Use higher voltage.

3. Variable speed/continuous use.

Most builders install thrusters that work fine with up to 15 knots wind or so and for about 60 seconds or so. Bigger and longer running are better - especially when you need it most!

FF

Guru

- Joined

- Oct 12, 2007

- Messages

- 22,552

ONLY have a yard that has installed a couple of dozen do the work.

Too many problem areas to treat a yard to a Learning Experience.

Too many problem areas to treat a yard to a Learning Experience.

Why not do it yourself. If time out of water is an issue, install the tube and lower leg, launch her and finish up in water, I did it in a weekend. It's not a difficult job if you plan it out carefully before starting. This will save you $$$$$$

healhustler

Guru

- Joined

- Oct 2, 2009

- Messages

- 5,198

- Location

- USA

- Vessel Name

- Bucky

- Vessel Make

- Krogen Manatee 36 North Sea

Why not do it yourself. If time out of water is an issue, install the tube and lower leg, launch her and finish up in water, I did it in a weekend. It's not a difficult job if you plan it out carefully before starting. This will save you $$$$$$

Hey Poke.....I don't suppose they sent you the hole saw in the installation kit did they? With a cored hull, I'm scared of making an alignment error on my own, otherwise I'd have swapped mine out for a fresh 7 hp long ago.

Hey Poke.....I don't suppose they sent you the hole saw in the installation kit did they? With a cored hull, I'm scared of making an alignment error on my own, otherwise I'd have swapped mine out for a fresh 7 hp long ago.

No holesaw required. The instruction for tube installation actually came with the thruster.

First thing is to locate the center point of the hole on either side of the bow. You can do this with a jig or intersecting arcs drawn in pencil.

Then drill a 1/4" hole at that center point.

Buy a steel rod (I used stainless) bent into a "J" with the short end sharpened to a point. The bend should scibe a circle the same diameter as the tube.

Insert the long end through both 1/4" holes and rotate to scribe the shape with the sharp end. Then I cut it out with a jig saw.

If you look at the photo with the tube next to the boat you will see that I had already put the tube in place and marked it with magic marker for the final trim to shape.

The yard had quoted me 15k for the thruster and installation. I managed to get a 24v boat show display thruster (complete with acrylic display unit) for $2,200 and a series/parallel switch from a tractor for $150, $20 for a relay from an auto parts store and If I remember the tube was about $300 and the J-rod from a local machine shop for $30

Attachments

Last edited:

cardude01

Guru

- Joined

- Nov 26, 2012

- Messages

- 5,290

- Location

- USA

- Vessel Name

- Bijou

- Vessel Make

- 2008 Island Packet PY/SP

No holesaw required. The instruction for tube installation actually came with the thruster. First thing is to locate the center point of the hole on either side of the bow. You can do this with a jig or intersecting arcs drawn in pencil. Then drill a 1/4" hole at that center point. Buy a steel rod (I used stainless) bent into a "J" with the short end sharpened to a point. The bend should scibe a circle the same diameter as the tube. Insert the long end through both 1/4" holes and rotate to scribe the shape with the sharp end. Then I cut it out with a jig saw. If you look at the photo with the tube next to the boat you will see that I had already put the tube in place and marked it with magic marker for the final trim to shape. The yard had quoted me 15k for the thruster and installation. I managed to get a 24v boat show display thruster (complete with acrylic display unit) for $2,200 and a series/parallel switch from a tractor for $150, $20 for a relay from an auto parts store and If I remember the tube was about $300 and the J-rod from a local machine shop for $30

Wow. You have way more skills/cojones than me.

Sent from my iPhone using Trawler

No .... I'm a Scot. I just could'nt bring myself to fork over 15K. I thoroughly planned my approach, assembled everything I needed and ran through the job in my mind a hundred times. When I was ready to start .... well to be honest and sat and looked at it for a couple of weeks before I could drum up the courage to drill the first hole. I was scared shi..less. Once I got started it was much easier than I thought. I am totally convinced the average handyman could do this job with a little forethought.

RickB

Guru

- Joined

- Oct 20, 2007

- Messages

- 3,804

- Vessel Make

- CHB 48 Zodiac YL 4.2

No .... I'm a Scot. I just could'nt bring myself to fork over 15K.

On that. I did exactly the same thing with my own boat. Working up the courage to start is way harder than actually doing it.

On that. I did exactly the same thing with my own boat. Working up the courage to start is way harder than actually doing it. Besides, if the absolute worst happened and you really screwed up the job you will know when it happens and then you can hire an expert to fix the mess you made.

It only consumes a bit of pride and money in that case.

psneeld

Guru

Get to know someone who has worked with polyester or epoxy a lot and have them take a look, offer suggestions. In the last 13 years working in the boating trades and increasing complexity of composite work...it's pretty easy..but there are a few "gotcha's".

healhustler

Guru

- Joined

- Oct 2, 2009

- Messages

- 5,198

- Location

- USA

- Vessel Name

- Bucky

- Vessel Make

- Krogen Manatee 36 North Sea

Since I already have a thruster in the boat, the process of centering would not be so involved I suppose. The tube for a 7 HP unit is likely a bit larger in diameter than my own, so I guess I'd just scribe a larger diameter around the existing tube. Still.....?!?!

RickB

Guru

- Joined

- Oct 20, 2007

- Messages

- 3,804

- Vessel Make

- CHB 48 Zodiac YL 4.2

... I guess I'd just scribe a larger diameter around the existing tube.

That would make it much simpler. Keep in mind that the alignment isn't as critical as line boring a crankshaft or doing a shaft alignment. It really doesn't matter if the thrust is off a degree or three.

The connection to the hull is what matters most.

boatpoker, you got bigger huevos than I do. Ain't no way I'm going to attach my hull with any kind of saw.

The bid your yard gave you sounded really high. I got my thruster installed for $10K, and it was larger by two sizes than what the manufacturer's charts recommended for my boat.

I've never regretted upsizing. My boat weighs in the neighborhood of 65,000 pounds loaded (full fuel and water, etc.) and I've found the thruster really moves it. If I stay on the control for more than a few seconds the boat builds up too much momentum and I have to give a shot in the opposite direction to stop the movement.

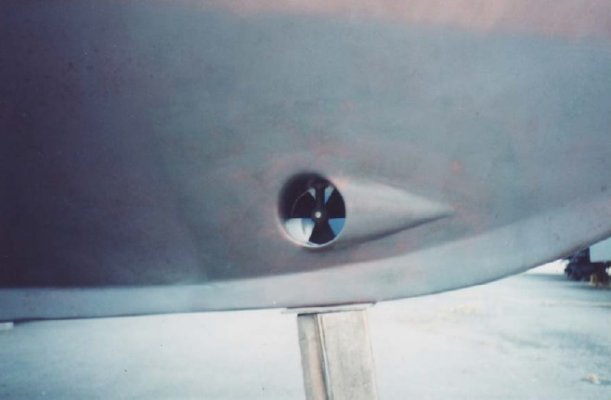

Here's a shot of what it looks like from the outside....

and from the inside of the hull. They installed four large 12V batteries so I have two in parallel and two in series for a 24V operation and lots of battery reserve.

I'm finding I don't use it as much as I thought I would. We live in a high wind area and most of the time I don't use it when I'm backing into the slip. We use it most when we're inside one of the locks on the Columbia or Snake rivers to hold the bow against the wall while getting our line secured to the bollard.

The bid your yard gave you sounded really high. I got my thruster installed for $10K, and it was larger by two sizes than what the manufacturer's charts recommended for my boat.

I've never regretted upsizing. My boat weighs in the neighborhood of 65,000 pounds loaded (full fuel and water, etc.) and I've found the thruster really moves it. If I stay on the control for more than a few seconds the boat builds up too much momentum and I have to give a shot in the opposite direction to stop the movement.

Here's a shot of what it looks like from the outside....

and from the inside of the hull. They installed four large 12V batteries so I have two in parallel and two in series for a 24V operation and lots of battery reserve.

I'm finding I don't use it as much as I thought I would. We live in a high wind area and most of the time I don't use it when I'm backing into the slip. We use it most when we're inside one of the locks on the Columbia or Snake rivers to hold the bow against the wall while getting our line secured to the bollard.

Rekindle

Veteran Member

I've got a 5HP Lewmar on my 25,000 lb. Manatee and it is marginal at best. Another friend's Manatee has a later model 7 HP Sidepower and it kicks "A".

I've just purchased a KK42 that had a 4HP(3kW) Lewmar, 12v. I'm in the process of changing it out to a 7.6HP (5.7kW) Lewmar, 24v. No glass work as the tube size is the same. Adding two Optimas nearby. Since I'm nearly doubling the HP and switching to 24v I'm hoping to see some big gains without the price tag of a complete refit. I'll report the results when I get her back in the water.

I've just purchased a KK42 that had a 4HP(3kW) Lewmar, 12v. I'm in the process of changing it out to a 7.6HP (5.7kW) Lewmar, 24v. No glass work as the tube size is the same. Adding two Optimas nearby. Since I'm nearly doubling the HP and switching to 24v I'm hoping to see some big gains without the price tag of a complete refit. I'll report the results when I get her back in the water.

There will be no surprise ..... the 24volts, the 5.7kW and the Optimas which can unload current faster than conventional wet cells will be massive difference. put your seat belt on

Ski in NC

Technical Guru

I installed a sidepower on mine about 6yrs ago. Unit has been very reliable. Can't remember model/hp, but it was 2nd from largest for the 8" tube. That way if I need to upgrade, tube needs no change.

Installing the tube is nothing special- The j-tip steel rod is key. I went a step further and made a J-type jig that held a die grinder with carbide tip. That way as I swept it around, I was actually doing the cutting with tip parallel to axis. I did not cut all the way through, keeping some material intact to hold jig in place. Made for a clean hole with minimal grinding to fit tube. Your eye really plays tricks on you when viewing the various curves. Trust the jig!!!!

Another trick was to transfer measurments from outside to inside hull or vs versa- Not easily done without drilling holes!! Came up with a trick: Got a big strong magnet and positioned on hull skin. Got some little needle bearings and sprinkled them on other side of skin. They stuck at the magnet location. Now you know where you are both in and out.

Mount thruster as low and as far fwd as you can. Mine is a planing hull, so I had a additional complication as I wanted thruster above running WL. Not really necessary in hindsight, as if faired well the hole does not present much drag. Anyway, tube ended up right on top of keel so I could go no lower.

Put battery right next to unit. 24v much better for larger units. I use 12v, and have a charge link via 10ga wire back to house batt. I installed a relay in the charge link so it goes open circuit when thruster motor runs. That keeps from overloading charge link and allows a light cable run. 20a breaker does not trip. There is no other charge source for the batt, super simple and it works.

If you use a series/parallel solenoid, you can run your 24v thruster and charge from a 12v source.

I would not go hydraulic on a smaller recreational boat. Too much complication and mess. If you find yourself over running your batts, you can always upsize batts.

I run a basic grp 24 starting batt. It's cheap, light, but only lasts about 3yrs before it starts losing grunt. May try a deep cycle next.

Installing the tube is nothing special- The j-tip steel rod is key. I went a step further and made a J-type jig that held a die grinder with carbide tip. That way as I swept it around, I was actually doing the cutting with tip parallel to axis. I did not cut all the way through, keeping some material intact to hold jig in place. Made for a clean hole with minimal grinding to fit tube. Your eye really plays tricks on you when viewing the various curves. Trust the jig!!!!

Another trick was to transfer measurments from outside to inside hull or vs versa- Not easily done without drilling holes!! Came up with a trick: Got a big strong magnet and positioned on hull skin. Got some little needle bearings and sprinkled them on other side of skin. They stuck at the magnet location. Now you know where you are both in and out.

Mount thruster as low and as far fwd as you can. Mine is a planing hull, so I had a additional complication as I wanted thruster above running WL. Not really necessary in hindsight, as if faired well the hole does not present much drag. Anyway, tube ended up right on top of keel so I could go no lower.

Put battery right next to unit. 24v much better for larger units. I use 12v, and have a charge link via 10ga wire back to house batt. I installed a relay in the charge link so it goes open circuit when thruster motor runs. That keeps from overloading charge link and allows a light cable run. 20a breaker does not trip. There is no other charge source for the batt, super simple and it works.

If you use a series/parallel solenoid, you can run your 24v thruster and charge from a 12v source.

I would not go hydraulic on a smaller recreational boat. Too much complication and mess. If you find yourself over running your batts, you can always upsize batts.

I run a basic grp 24 starting batt. It's cheap, light, but only lasts about 3yrs before it starts losing grunt. May try a deep cycle next.

Last edited:

Ben

Guru

- Joined

- Dec 10, 2007

- Messages

- 758

- Location

- US

- Vessel Name

- Silver Lining

- Vessel Make

- Heritage East 44 / Twin Perkins T6.3544

No .... I'm a Scot. I just could'nt bring myself to fork over 15K. I thoroughly planned my approach, assembled everything I needed and ran through the job in my mind a hundred times. When I was ready to start .... well to be honest and sat and looked at it for a couple of weeks before I could drum up the courage to drill the first hole. I was scared shi..less. Once I got started it was much easier than I thought. I am totally convinced the average handyman could do this job with a little forethought.

This is my logic as well. I get a quote. Then I get thoroughly disgusted. Then I plan the job myself. Then I execute. I'm not up to bow thruster skill just yet - maybe a long ways away, but I have done this way because contractors have pissed me off with high quotes and jackass attitudes. I'm at the early point in the learning curve on many projects, but building skills and knowledge gradually.

My hat's off to you boat poker, well done.

mbevins

Guru

This is my logic as well. I get a quote. Then I get thoroughly disgusted. Then I plan the job myself. Then I execute. I'm not up to bow thruster skill just yet - maybe a long ways away, but I have done this way because contractors have pissed me off with high quotes and jackass attitudes. I'm at the early point in the learning curve on many projects, but building skills and knowledge gradually.

My hat's off to you boat poker, well done.

It never ceases to amaze me how naive and stupid most of these installers think we are. On certain things I will consider hiring it out mainly because of my time cost vs the $ cost of the contractor. But some of these guys think they're worth hundreds per hour and we should pay it because it starts with BOAT. In actuality there is very little most of us can't do on our boats. It might take us a little bit longer but so be it.

Sent from my Nexus 7 using Trawler

psneeld

Guru

It never ceases to amaze me how naive and stupid most of these installers think we are. On certain things I will consider hiring it out mainly because of my time cost vs the $ cost of the contractor. But some of these guys think they're worth hundreds per hour and we should pay it because it starts with BOAT. In actuality there is very little most of us can't do on our boats. It might take us a little bit longer but so be it.

Sent from my Nexus 7 using Trawler

Funny, I feel the exact same way about ANYONE who charges hundreds per hour....boy that's starting to sound like a lot of different businesses and professions.....

Ben

Guru

- Joined

- Dec 10, 2007

- Messages

- 758

- Location

- US

- Vessel Name

- Silver Lining

- Vessel Make

- Heritage East 44 / Twin Perkins T6.3544

Funny, I feel the exact same way about ANYONE who charges hundreds per hour....boy that's starting to sound like a lot of different businesses and professions.....

My last was $80 per hour but estimated "30-40 hours" to swap the water hoses and pump on my Lehman.. My slow ass with bad tools could learn it and do it 4 times in that amount of time.

Similar threads

- Replies

- 27

- Views

- 2K

- Replies

- 7

- Views

- 976