tiku

Veteran Member

Hi!

I decided to tackle some drive train maintenance this haul-out season. On the to do list are:

-changing stuffing box hoses

-dealing with bent strut

-replace strut bearings

-etc...

I ran into a problem with my port engine and more specifically with the strut. As you can see the axle is not really in the center and the bearing has worn quite heavily.

Another clue as to something is wrong is where the axle enters the hull. There is an area, roughly 10 cm long where I have nice shiny metal. In other words the axle is touching the hull. Lightly but still, it's not right.

The props are off (it was another battle, read more from the blog) and the starboard strut is fine and the bearing shows no uneven wear but I'll change it anyway.

Tonight I disconnected the coupling from the transmission and I was wondering if the axle is going to shoot to some direction due to the bent strut but no, it seems to be dead on.

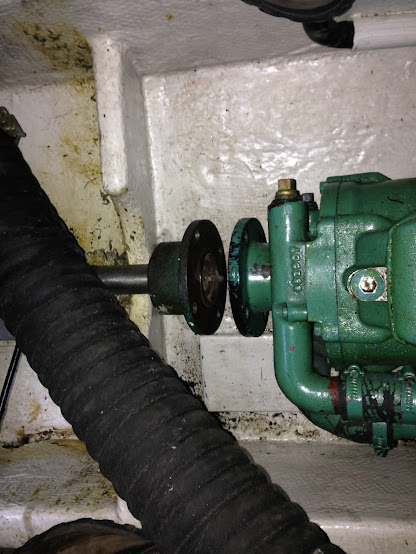

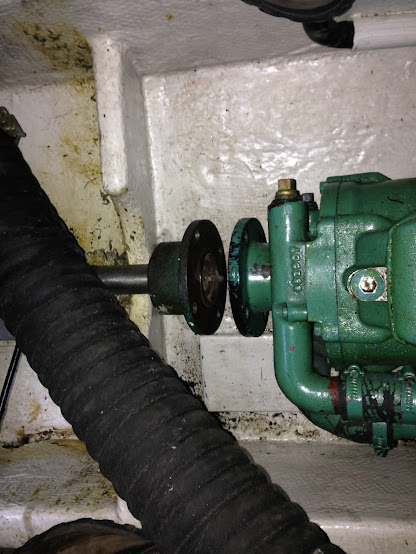

As you can see, we are talking about picture perfect alignment here.

So this leads me to wonder how is it possible? The strut is bent, I can see it with my eyes and the axle is eating into the strut bearing but still the coupling end shows no misalignment and during the season there were no vibrations.

Should I proceed with the strut? Drop it off and have it straightened or buy a new one? Or am I killing the drive train softly if I just reassemble it "as is" after doing the maintenance.

Logic says to go the long way, but I'm wondering why the axle is not showing any misalignment in the coupling end?

To my knowledge there is no bearing in the "axle tube" and my stuffing boxes are of the hose type so they don't really offer support...

I decided to tackle some drive train maintenance this haul-out season. On the to do list are:

-changing stuffing box hoses

-dealing with bent strut

-replace strut bearings

-etc...

I ran into a problem with my port engine and more specifically with the strut. As you can see the axle is not really in the center and the bearing has worn quite heavily.

Another clue as to something is wrong is where the axle enters the hull. There is an area, roughly 10 cm long where I have nice shiny metal. In other words the axle is touching the hull. Lightly but still, it's not right.

The props are off (it was another battle, read more from the blog) and the starboard strut is fine and the bearing shows no uneven wear but I'll change it anyway.

Tonight I disconnected the coupling from the transmission and I was wondering if the axle is going to shoot to some direction due to the bent strut but no, it seems to be dead on.

As you can see, we are talking about picture perfect alignment here.

So this leads me to wonder how is it possible? The strut is bent, I can see it with my eyes and the axle is eating into the strut bearing but still the coupling end shows no misalignment and during the season there were no vibrations.

Should I proceed with the strut? Drop it off and have it straightened or buy a new one? Or am I killing the drive train softly if I just reassemble it "as is" after doing the maintenance.

Logic says to go the long way, but I'm wondering why the axle is not showing any misalignment in the coupling end?

To my knowledge there is no bearing in the "axle tube" and my stuffing boxes are of the hose type so they don't really offer support...