skipperdude

Guru

Marin, Am I to understand you own a DeHavaland Beaver?

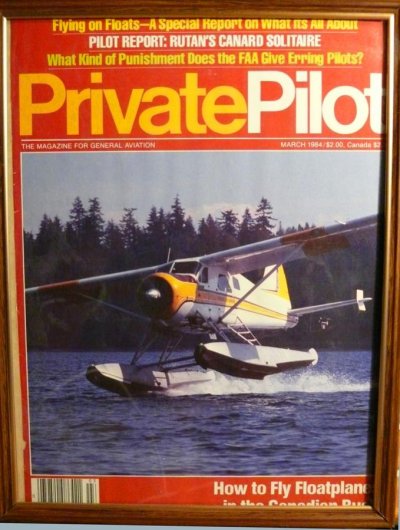

I have a short tale to relate on my experience with a 1947 vintage Beaver.

I was on a moose hunt up in the Brooks range. We flew out of Bettles Alaska to the south fork of the Malmute river to a small lake. Landed with no problems. after a 4 day unsucessful hunt the Beaver came back to pick us up. The lake was quite small and sort of kidney shaped. in order to have enough room to take off the pilot backed all the way into the back corner of the lake and as we were gaining speed to lift off he had to sort of roll the Beaver up on one pontoon as we rounded the corner of the lake.

She popped right off the water and we were on our way. Man was I impressed.

As a side note I did find a winter drop of antlers on the side of the lake.

While driving back from Fairbanks I found a place on the side of the road where a hunter had left a moose hide. I tossed it into my truck. I wound up having it tanned into garment leather. I cut it up and my wife sewed it together to make a moose hide coat . We entered it into the Alaska State fare and won a blue ribbon Best of show for the coat.

So my beaver tale wound up with a hollow moose. I got everything but the meat.

One impressive piece of equipment That Beaver, It being older than me.

SD

I have a short tale to relate on my experience with a 1947 vintage Beaver.

I was on a moose hunt up in the Brooks range. We flew out of Bettles Alaska to the south fork of the Malmute river to a small lake. Landed with no problems. after a 4 day unsucessful hunt the Beaver came back to pick us up. The lake was quite small and sort of kidney shaped. in order to have enough room to take off the pilot backed all the way into the back corner of the lake and as we were gaining speed to lift off he had to sort of roll the Beaver up on one pontoon as we rounded the corner of the lake.

She popped right off the water and we were on our way. Man was I impressed.

As a side note I did find a winter drop of antlers on the side of the lake.

While driving back from Fairbanks I found a place on the side of the road where a hunter had left a moose hide. I tossed it into my truck. I wound up having it tanned into garment leather. I cut it up and my wife sewed it together to make a moose hide coat . We entered it into the Alaska State fare and won a blue ribbon Best of show for the coat.

So my beaver tale wound up with a hollow moose. I got everything but the meat.

One impressive piece of equipment That Beaver, It being older than me.

SD