BaltimoreLurker

Curmudgeon

- Joined

- Oct 8, 2007

- Messages

- 2,775

- Location

- USA

- Vessel Name

- Moon Dance

- Vessel Make

- 1974 34' Marine Trader Sedan

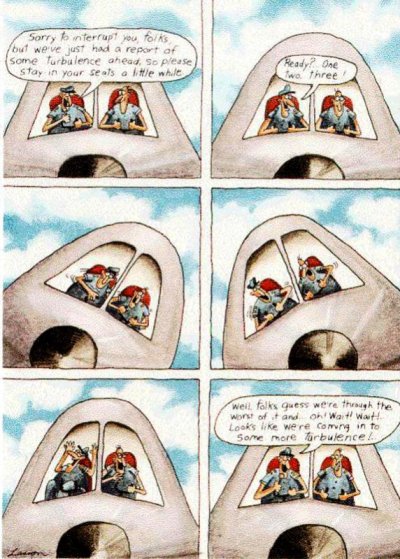

Something from a friend of a friend. Damn! And I though my old P3 A/B was a complex beast.

787 Features & Differences

I just completed the first pilot training class on the 787 at United Airlines, an airplane which is destined to replace the 767 and live for many years after I retire. Here's what I've learned in 787 training so far. By the way, last night we passed our MV (maneuvers validation) check ride, with emergency after emergency, and the FAA observing. Tonight was our LOE (line-oriented evaluation), again with FAA - this time 2 FAA observers. It's 0200 and I just got back to the hotel and poured a well-earned glass of wine to celebrate. I now have a type rating in the 787. Phew. I'm pretty confident this will be the last one for me.

I've summarized some of the major differences and unique features of the 787 versus more traditional "old school" airplanes like the 777 (not kidding) - from the pilot's viewpoint. Our "Differences" course takes 11 days to gain an FAA type rating, which is a "common" type rating with the 777. The course has been like drinking from a fire hose, but has finally come together. Some of our pilots attended Boeing's 5-day differences course, and deemed it unacceptable. The FAA approved the Boeing 5-day course, but our guys decided it lacked too much information. FAA is observing our checkrides now, and taking our course as well, to certify the training. We're just the guinea pigs.

A computer nerd would describe the 787 as 17 computer servers packaged in a kevlar frame. The central brains is the Common Core System (CCS). Two Common Computing Resources (CCRs) coordinate the communications of all the computer systems, isolating faults and covering failed systems with working systems. When battery power is first applied to the airplane in the morning, it takes about 50 seconds for the L CCR to boot up. After this, a few displays light up and you can start the APU. If there is a major loss of cockpit displays, this may require a CCR reboot, which would take about a minute. Here are a few of the major features and differences from the 777.

Electrics - Though a smaller plane, the 787 has 4 times the electric generating power of the 777 - 1.4 gigawatts. Generators produce 235 VAC for the big power users. Other systems use the traditional 115 VAC and 28 VDC. There are 17 scattered Remote Power Distribution Units which power about 900 loads throughout the plane. The big power distribution system is in the aft belly, along with a Power Electronics Cooling System (PECS). This is a liquid cooling system for the large motor power distribution system. There's also an Integrated Cooling System (ICS), which provides refrigerated air for the galley carts and cabin air, and a Miscellaneous Equipment Cooling System for Inflight Entertainment Equipment.

If 3 of the 4 engine generators fail, the APU starts itself. The APU drives two generators, and can be operated up to the airplane's max altitude of 43,000 feet. If you lose all 4 engine generators, the RAT (ram air turbine) drops out (like a windmill), powering essential buses. (It also provides hydraulic power to flight controls if needed).

If you lose all 4 engine generators and the two APU generators (a really bad day), you are down to Standby Power. The RAT will drop out and provide power, but even if it fails, you still have the autopilot and captain's flight director and instruments, FMC, 2 IRSs, VHF radios, etc. If you're down to batteries only, with no RAT, you'd better get it on the ground, as battery time is limited. Brakes and antiskid are electric - 28V - so you don't lose brakes or antiskid even when you're down to just standby power.

Normal flight controls are hydraulic with a couple exceptions. Engine driven and electric hydraulic pumps operate at 5000 psi (versus normal 3000 psi) to allow for smaller tubing sizes and actuators, thus saving weight. If you lose all 3 hydraulic systems (another bad day), you still have two spoiler panels on each wing which are electrically powered all the time, as is the stabilizer trim. You can still fly the airplane (no flaps, though). If you're having an even worse day and you lose all hydraulics and all generators, flight control power is still coming from separate Permanent Magnet Generators (PMGs) which produce power even if both engines quit and are windmilling. If the PMGs fail, too, your flight controls will be powered by the 28 V standby bus.

If you lose all 3 pitot/static systems or air data computers, the airplane reverts to angle of attack speed (converts AOA to IAS), and this is displayed on the normal PFDs (primary flight displays) airspeed indicator tapes. GPS altitude is substituted for air data altitude and displayed on the PFD altimeter tapes. Very convenient.

If you lose both Attitude and Heading Reference Units (AHRUs), it reverts to the standby instrument built-in attitude & heading gyro, but displays this on both pilot's PFDs for convenience.

If you lose both Inertial Reference Units, it will substitute GPS position, and nothing is lost.

If someone turns one or both IRSs off in flight (I hate it when they do that), you can realign them - as long as one of the GPSs is working!

There is no pneumatic system. The only engine bleed is used for that engine's anti-ice. Wing anti-ice is electric. Each of two air conditioning packs control two CACs, which are electric cabin air compressors. The four CACs share two air inlets on the belly. Each pack controller controls two CACs, but if a pack controller fails, the remaining pack controller takes over control of all 4 CACs.

There are no circuit breakers in the cockpit. To check on them, or if you get a message that one has opened (more likely), you select the CBIC (circuit breaker indication and control) display on one of the MFDs (multi function displays). There you can reset the virtual C/B if it is an "electronic" circuit breaker. You can't reset a popped "thermal" circuit breaker.

If you have an APU fire on the ground or inflight, the fire extinguishing bottle is automatically discharged. If there is a cargo fire, the first two of seven bottles will automatically discharge also.

There's a Nitrogen Generation System which provides automatic full-time flammability protection by displacing fuel vapors in the fuel tanks with nitrogen (Remember TWA 800?).

Like the 767 and 777, the 787 also has full CPDLC capability (controller-to-pilot datalink communications). In addition, its full FANS capability includes ADS-B in & out. The controller can uplink speed, heading, and altitude changes to the airplane. These show up on a second line right under the speed, heading and altitude displays on the mode control panel. If you pilot wants to use them, he can press a XFR button next to each window. The controller can even uplink a conditional clearance, like - After passing point XYZ, climb to FL390. If you accept this, it will do it automatically.

Fuel system - like the 777, the 787 has a fuel dump system which automatically dumps down to your maximum landing weight, if that is what you want. In addition, it has a Fuel Balance switch which automatically balances your L & R main tanks for you. No more opening crossfeed valves and turning off fuel pumps in flight. No more forgetting to turn them back on, either.

Flight Controls - An "Autodrag" function operates when the airplane is high on approach and landing flaps have been selected. It extends the ailerons and two most outboard spoilers, while maintaining airspeed, to assist in glidepath capture from above, if you are high on the glideslope. The feature removes itself below 500 feet.

Cruise flaps is an automated function when level at cruise. It symmetrically moves the flaps, ailerons, flaperons, and spoilers based on weight, airspeed and altitude to optimize cruise performance by varying the wing camber, thus reducing drag.

Gust suppression - Vertical gust suppression enhances ride quality when in vertical gusts and turbulence. It uses symmetric deflection of flaperons and elevators to smooth the bumps. This should result in fewer whitecaps in passengers' coffee and cocktails. Lateral gust suppression improves the ride when on approach by making yaw commands in response to lateral gusts and turbulence.

Instrument Approaches - The airplane is actually approved for autoland based not only on ILS but on GLS approaches - GPS with Ground based augmentation system, which corrects the GPS signals. GLS minimums are the same as CAT I ILSs - 200' and 1/2 mile visibility. Our airline is not yet approved for GLS autolandings yet, though we will be doing GLS approaches.

Special Cat I & II HUD approaches - These allow lower than normal minimums when the Heads Up Devices are used at certain approved airports (HUDs). The HUDs include runway centerline guidance which helps you stay on the centerline on takeoff when visibility is greatly reduced. It uses either ILS or GLS for this.

Cabin - Pressurization differential pressure maximum is 9.4 psid, so the cabin altitude is only 6000 feet when at the max cruising altitude of 43,000 feet. There is a cockpit humidifier switch, and cabin air humidification is fully automatic. Cabin windows are larger than other airplanes, and window shading is electronic. The passenger can select 5 levels of shading, from clear to black. The flight attendants can control the cabin lighting temperature - mood lighting - to aid in dealing with changing time zones (evening light after dinner, morning light to wake up, etc.).

Much of the cockpit seems like it was designed by Apple. The Control Display Units (CDUs) are virtual, so you can move them from one MFD to another. In fact, you can configure the displays in 48 different ways, I think, though we have found a few favorites we will use to keep it simple. To move the cursor from one MFD to another, you can either use a button, or you can "flick" your finger across the trackpad (Cursor Control Device) to fling the cursor from one screen to the next - much like an iPad.

I'm going home this morning, and will return for a 777 simulator ride before I go back to work. They want to make sure we've still got the old-fashioned legacy airplane in our brain before we fly the 777 again, even though it shares a "common type rating". We won't get the first 787 until October, and begin operations in November or December. At that time I'll return for at least 4 days refresher training before beginning IOE - initial operating experience in the airplane - with passengers.

What a ride. It may be "fuel efficient", but I'm glad someone else is paying for the gas.

787 Features & Differences

I just completed the first pilot training class on the 787 at United Airlines, an airplane which is destined to replace the 767 and live for many years after I retire. Here's what I've learned in 787 training so far. By the way, last night we passed our MV (maneuvers validation) check ride, with emergency after emergency, and the FAA observing. Tonight was our LOE (line-oriented evaluation), again with FAA - this time 2 FAA observers. It's 0200 and I just got back to the hotel and poured a well-earned glass of wine to celebrate. I now have a type rating in the 787. Phew. I'm pretty confident this will be the last one for me.

I've summarized some of the major differences and unique features of the 787 versus more traditional "old school" airplanes like the 777 (not kidding) - from the pilot's viewpoint. Our "Differences" course takes 11 days to gain an FAA type rating, which is a "common" type rating with the 777. The course has been like drinking from a fire hose, but has finally come together. Some of our pilots attended Boeing's 5-day differences course, and deemed it unacceptable. The FAA approved the Boeing 5-day course, but our guys decided it lacked too much information. FAA is observing our checkrides now, and taking our course as well, to certify the training. We're just the guinea pigs.

A computer nerd would describe the 787 as 17 computer servers packaged in a kevlar frame. The central brains is the Common Core System (CCS). Two Common Computing Resources (CCRs) coordinate the communications of all the computer systems, isolating faults and covering failed systems with working systems. When battery power is first applied to the airplane in the morning, it takes about 50 seconds for the L CCR to boot up. After this, a few displays light up and you can start the APU. If there is a major loss of cockpit displays, this may require a CCR reboot, which would take about a minute. Here are a few of the major features and differences from the 777.

Electrics - Though a smaller plane, the 787 has 4 times the electric generating power of the 777 - 1.4 gigawatts. Generators produce 235 VAC for the big power users. Other systems use the traditional 115 VAC and 28 VDC. There are 17 scattered Remote Power Distribution Units which power about 900 loads throughout the plane. The big power distribution system is in the aft belly, along with a Power Electronics Cooling System (PECS). This is a liquid cooling system for the large motor power distribution system. There's also an Integrated Cooling System (ICS), which provides refrigerated air for the galley carts and cabin air, and a Miscellaneous Equipment Cooling System for Inflight Entertainment Equipment.

If 3 of the 4 engine generators fail, the APU starts itself. The APU drives two generators, and can be operated up to the airplane's max altitude of 43,000 feet. If you lose all 4 engine generators, the RAT (ram air turbine) drops out (like a windmill), powering essential buses. (It also provides hydraulic power to flight controls if needed).

If you lose all 4 engine generators and the two APU generators (a really bad day), you are down to Standby Power. The RAT will drop out and provide power, but even if it fails, you still have the autopilot and captain's flight director and instruments, FMC, 2 IRSs, VHF radios, etc. If you're down to batteries only, with no RAT, you'd better get it on the ground, as battery time is limited. Brakes and antiskid are electric - 28V - so you don't lose brakes or antiskid even when you're down to just standby power.

Normal flight controls are hydraulic with a couple exceptions. Engine driven and electric hydraulic pumps operate at 5000 psi (versus normal 3000 psi) to allow for smaller tubing sizes and actuators, thus saving weight. If you lose all 3 hydraulic systems (another bad day), you still have two spoiler panels on each wing which are electrically powered all the time, as is the stabilizer trim. You can still fly the airplane (no flaps, though). If you're having an even worse day and you lose all hydraulics and all generators, flight control power is still coming from separate Permanent Magnet Generators (PMGs) which produce power even if both engines quit and are windmilling. If the PMGs fail, too, your flight controls will be powered by the 28 V standby bus.

If you lose all 3 pitot/static systems or air data computers, the airplane reverts to angle of attack speed (converts AOA to IAS), and this is displayed on the normal PFDs (primary flight displays) airspeed indicator tapes. GPS altitude is substituted for air data altitude and displayed on the PFD altimeter tapes. Very convenient.

If you lose both Attitude and Heading Reference Units (AHRUs), it reverts to the standby instrument built-in attitude & heading gyro, but displays this on both pilot's PFDs for convenience.

If you lose both Inertial Reference Units, it will substitute GPS position, and nothing is lost.

If someone turns one or both IRSs off in flight (I hate it when they do that), you can realign them - as long as one of the GPSs is working!

There is no pneumatic system. The only engine bleed is used for that engine's anti-ice. Wing anti-ice is electric. Each of two air conditioning packs control two CACs, which are electric cabin air compressors. The four CACs share two air inlets on the belly. Each pack controller controls two CACs, but if a pack controller fails, the remaining pack controller takes over control of all 4 CACs.

There are no circuit breakers in the cockpit. To check on them, or if you get a message that one has opened (more likely), you select the CBIC (circuit breaker indication and control) display on one of the MFDs (multi function displays). There you can reset the virtual C/B if it is an "electronic" circuit breaker. You can't reset a popped "thermal" circuit breaker.

If you have an APU fire on the ground or inflight, the fire extinguishing bottle is automatically discharged. If there is a cargo fire, the first two of seven bottles will automatically discharge also.

There's a Nitrogen Generation System which provides automatic full-time flammability protection by displacing fuel vapors in the fuel tanks with nitrogen (Remember TWA 800?).

Like the 767 and 777, the 787 also has full CPDLC capability (controller-to-pilot datalink communications). In addition, its full FANS capability includes ADS-B in & out. The controller can uplink speed, heading, and altitude changes to the airplane. These show up on a second line right under the speed, heading and altitude displays on the mode control panel. If you pilot wants to use them, he can press a XFR button next to each window. The controller can even uplink a conditional clearance, like - After passing point XYZ, climb to FL390. If you accept this, it will do it automatically.

Fuel system - like the 777, the 787 has a fuel dump system which automatically dumps down to your maximum landing weight, if that is what you want. In addition, it has a Fuel Balance switch which automatically balances your L & R main tanks for you. No more opening crossfeed valves and turning off fuel pumps in flight. No more forgetting to turn them back on, either.

Flight Controls - An "Autodrag" function operates when the airplane is high on approach and landing flaps have been selected. It extends the ailerons and two most outboard spoilers, while maintaining airspeed, to assist in glidepath capture from above, if you are high on the glideslope. The feature removes itself below 500 feet.

Cruise flaps is an automated function when level at cruise. It symmetrically moves the flaps, ailerons, flaperons, and spoilers based on weight, airspeed and altitude to optimize cruise performance by varying the wing camber, thus reducing drag.

Gust suppression - Vertical gust suppression enhances ride quality when in vertical gusts and turbulence. It uses symmetric deflection of flaperons and elevators to smooth the bumps. This should result in fewer whitecaps in passengers' coffee and cocktails. Lateral gust suppression improves the ride when on approach by making yaw commands in response to lateral gusts and turbulence.

Instrument Approaches - The airplane is actually approved for autoland based not only on ILS but on GLS approaches - GPS with Ground based augmentation system, which corrects the GPS signals. GLS minimums are the same as CAT I ILSs - 200' and 1/2 mile visibility. Our airline is not yet approved for GLS autolandings yet, though we will be doing GLS approaches.

Special Cat I & II HUD approaches - These allow lower than normal minimums when the Heads Up Devices are used at certain approved airports (HUDs). The HUDs include runway centerline guidance which helps you stay on the centerline on takeoff when visibility is greatly reduced. It uses either ILS or GLS for this.

Cabin - Pressurization differential pressure maximum is 9.4 psid, so the cabin altitude is only 6000 feet when at the max cruising altitude of 43,000 feet. There is a cockpit humidifier switch, and cabin air humidification is fully automatic. Cabin windows are larger than other airplanes, and window shading is electronic. The passenger can select 5 levels of shading, from clear to black. The flight attendants can control the cabin lighting temperature - mood lighting - to aid in dealing with changing time zones (evening light after dinner, morning light to wake up, etc.).

Much of the cockpit seems like it was designed by Apple. The Control Display Units (CDUs) are virtual, so you can move them from one MFD to another. In fact, you can configure the displays in 48 different ways, I think, though we have found a few favorites we will use to keep it simple. To move the cursor from one MFD to another, you can either use a button, or you can "flick" your finger across the trackpad (Cursor Control Device) to fling the cursor from one screen to the next - much like an iPad.

I'm going home this morning, and will return for a 777 simulator ride before I go back to work. They want to make sure we've still got the old-fashioned legacy airplane in our brain before we fly the 777 again, even though it shares a "common type rating". We won't get the first 787 until October, and begin operations in November or December. At that time I'll return for at least 4 days refresher training before beginning IOE - initial operating experience in the airplane - with passengers.

What a ride. It may be "fuel efficient", but I'm glad someone else is paying for the gas.