We have ACCO 3/8" G4 (G43). It's marked every link. We're getting ready to replace it. A local shop had some that was stamped G4, marked 1 link per foot and made in China. We passed.

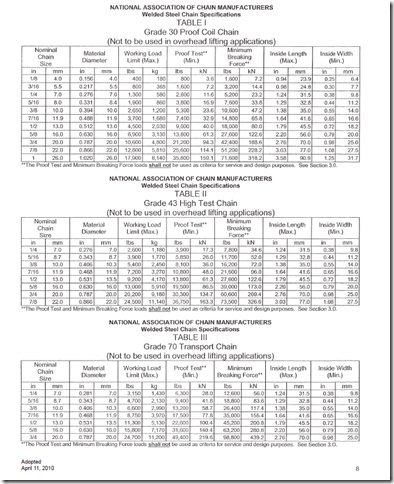

The published SWL for G30 is 2650lb and for G4 is 5400lb. I know for us to change to G30, the gypsy would have to changed out at ~$350.

Retriever: What did practical Sailor article say?

I might not totally knock Chinese chain. Peerless etc have an imported line of chain, I can only guess where they import from, but I am sure that they are very careful of the quality and I assume they import because it offers a cheaper option.

Most Chinese chain in chandlers outside America is unmarked. I wonder if the chain that you have declined has a manufacturer somewhere on the drums? I am under the impression, maybe erroneously, that chain sold in America for anchoring and I'm guessing lifting must be marked. I think it might also need to be marked with country of origin, though that might be by a code as embossing some countries on 5/16th inch might be difficult.

It is interesting you quote SWL, or WLL - this data for G30 and G43 bares comparison with the break strength, also quoted on the thread, if you look carefully you will note that G43 is sold to a 3:1 safety factor and G30 a 4;1 safety factor and the SWL data is 'misleading' if not put into context.

Gypsies, or replacement gypsies, are extorionate, but some 'upgrade' from G30 to G43 - and I wondered why. If you already have a G43 gypsy you are very unlikely to change unless you move to G70 and downsize (that's downsize the chain).

Does anyone know anyone who uses G70?

The imperial chain mark G4, means G43. Campbell mark their chain C4 (or C43) etc. ACCO usually mark with ACCO somewhere (and USA)

No-one has mentioned, yet, galvanising as an issue. Do some seabeds abrade more than others. So do people in Florida get a longer life, or less, than those in Seattle? etc.

Lots of questions

When you buy - how many ask for (and get) a test certificate for the batch they buy. Are you charged for the certificate?