You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Short inside inverter

- Thread starter Pack Mule

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

Lou_tribal

Guru

Well here it is .

These are terminal widely used in France, we call these Sugar (sucre in french) as they look like a piece of sugar. They are good when used correctly as they provide a solid connection.

However, like mentioned before in this thread, never put bare stranded wires in these without a ferrule or a crimped flat blade. If you do so, when you tighten the screw it will cut the strands. The result will be that the current will goes in some strands instead of all strands so the remaining uncut strands will get hot and melt the connector.

Martin J

Guru

Electric connections come loose in time and the connection may not have been as sound as one would like. I'd use the same and check all the connections. The fire may just have been a tad to much for the poor connections.

Again, the screw does not touch the wire itself. It pushes on a piece of metal that compresses the strands in place.These are terminal widely used in France, we call these Sugar (sucre in french) as they look like a piece of sugar. They are good when used correctly as they provide a solid connection.

However, like mentioned before in this thread, never put bare stranded wires in these without a ferrule or a crimped flat blade. If you do so, when you tighten the screw it will cut the strands. The result will be that the current will goes in some strands instead of all strands so the remaining uncut strands will get hot and melt the connector.

I worked in the electronics/electric field for over 30 years. Never needed a "ferrule" to terminate a wire. Never even heard of such a thing.

Lou_tribal

Guru

Again, the screw does not touch the wire itself. It pushes on a piece of metal that compresses the strands in place.

I worked in the electronics/electric field for over 30 years. Never needed a "ferrule" to terminate a wire. Never even heard of such a thing.

Wesk I think we are talking about two different things.

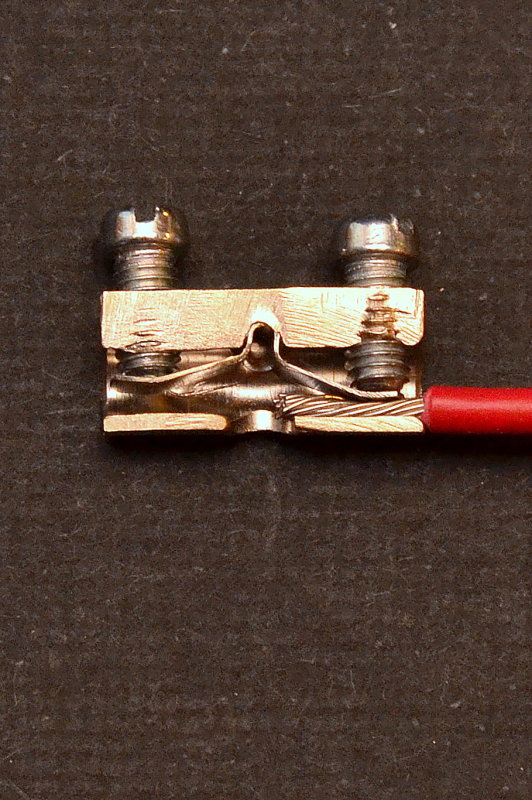

Some terminal block are indeed like you describe with a plate, pushed by a screw that tight the wire between two plate when you tighten the screw, a bit like this:

or this:

I am talking about this kind of thing:

And it is the screw that directly tighten the wire. I have a bunch of them at home, I can take a picture of one and the interior of the terminal.

The last one are widely use in Europe and requires ferrule to avoid the wire to be damaged. The ferrule is crimped over the stranded wire which give a solid base for the screw.

L.

Again, the screw does not touch the wire itself. It pushes on a piece of metal that compresses the strands in place.

In cheap Eurostrips/Euroblocks the screw very often impinges directly on the wire. In the last 15 or so years the onslaught of cheap junk has increased dramatically to the point that finding Eurostrips that do have a "pressure plate", as recommended by the ABYC safety standards, is getting tougher and tougher.

Any Eurostrip used on finely stranded wire should really have a pressure plate. The internal construction looks like this:

That said for an inverter like the Freedom, that uses Eurostrips, I generally prefer to upgrade to water-tight heat sealed butt splices crimped using the proper tooling.

It's not just Eurostrips/Euroblocks that don't use pressure plates, far too many so called "marine" items, including nav lights required by COLREGS / Federal Law lack the proper pressure plates they should have. One of the biggest offenders would be the AquaSignal Series 25 & 40 navigation lights where the screw directly impinges on the bare wire..

This was on a brand new vessel that proudly wore an ABYC and NMMA sticker.. It lacked any corrosion protection on the bare brass and also was not technically an ABYC compliant installation because the AquaSignal Series 25 lacks screw pressure plates:

I worked in the electronics/electric field for over 30 years. Never needed a "ferrule" to terminate a wire. Never even heard of such a thing.

Seems strange? I use them all the time & not just ferrules but tongue terminals too.

Items such as solar controllers often lack proper pressure plates for protecting the finely stranded wire..

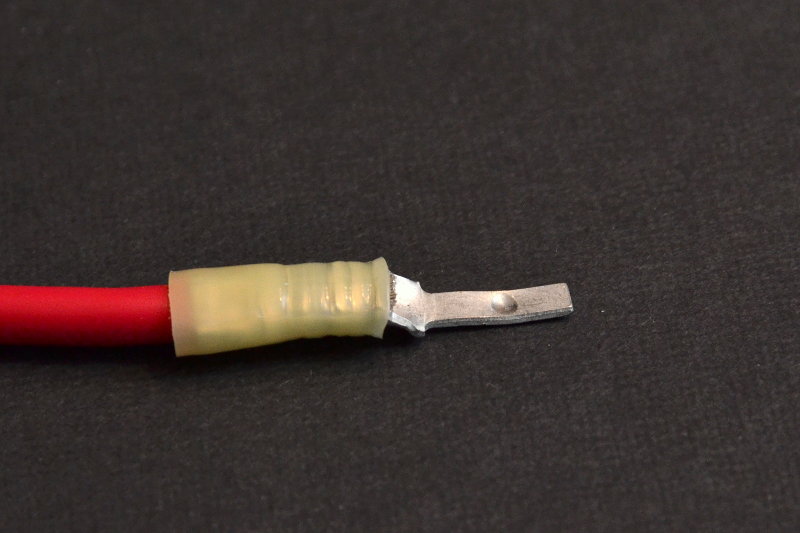

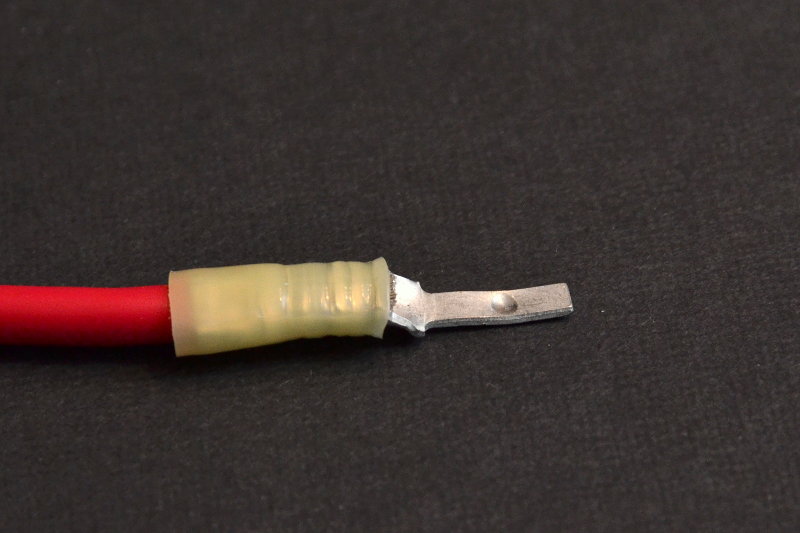

These are AMP PIDG blade/tongue terminals that I use to avoid the screws directly impinging on the finely stranded wire:

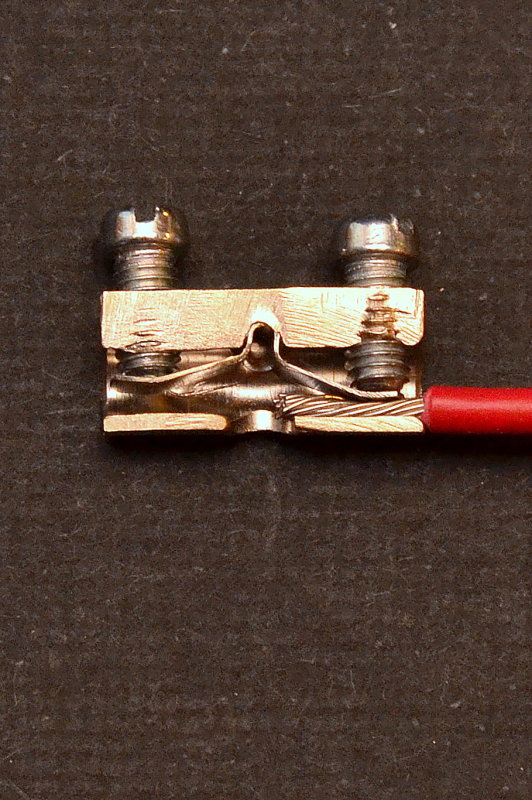

Here's the indent on the blade/tongue created by the screw:

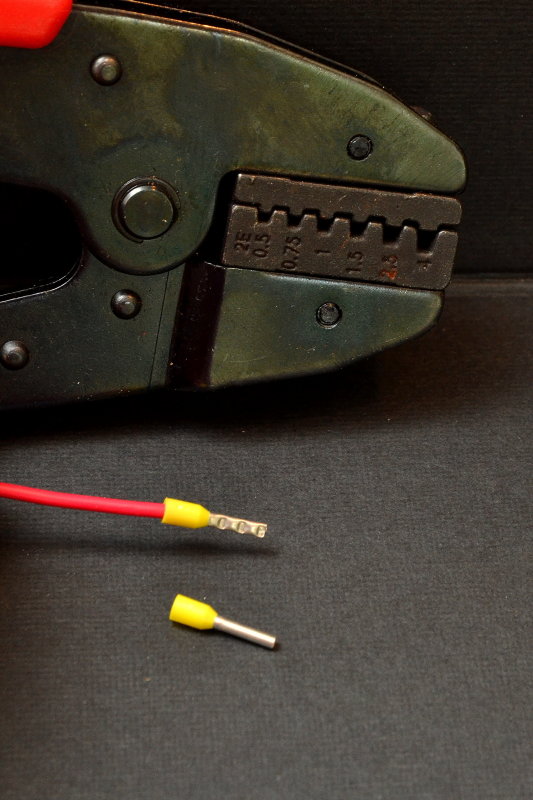

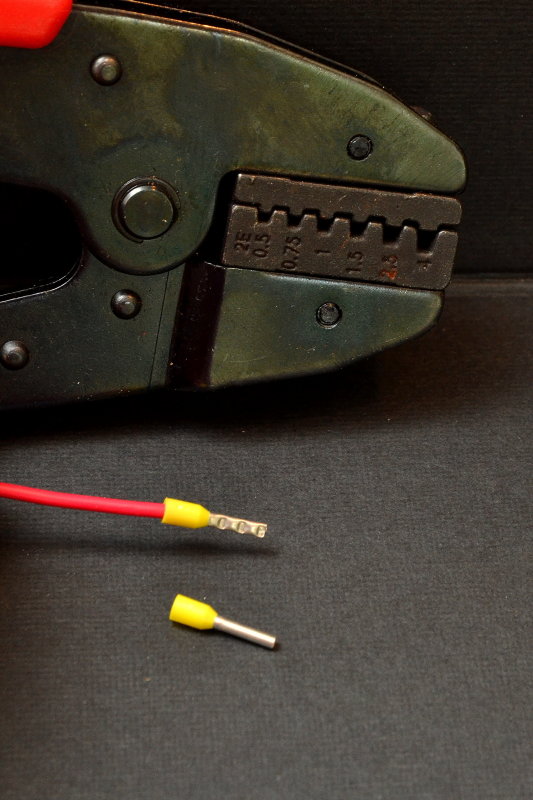

One can also use ferrules and a ferrule crimping tool.

Last edited:

Ferrule crimpers are on sale right now

At Amazon.com.

I own two of the PS charge controllers you displayed.

At Amazon.com.

I own two of the PS charge controllers you displayed.

In cheap Eurostrips/Euroblocks the screw very often impinges directly on the wire. In the last 15 or so years the onslaught of cheap junk has increased dramatically to the point that finding Eurostrips that do have a "pressure plate", as recommended by the ABYC safety standards, is getting tougher and tougher.

Any Eurostrip used on finely stranded wire should really have a pressure plate. The internal construction looks like this:

That said for an inverter like the Freedom, that uses Eurostrips, I generally prefer to upgrade to water-tight heat sealed butt splices crimped using the proper tooling.

It's not just Eurostrips/Euroblocks that don't use pressure plates, far too many so called "marine" items, including nav lights required by COLREGS / Federal Law lack the proper pressure plates they should have. One of the biggest offenders would be the AquaSignal Series 25 & 40 navigation lights where the screw directly impinges on the bare wire..

This was on a brand new vessel that proudly wore an ABYC and NMMA sticker.. It lacked any corrosion protection on the bare brass and also was not technically an ABYC compliant installation because the AquaSignal Series 25 lacks screw pressure plates:

Seems strange? I use them all the time & not just ferrules but tongue terminals too.

Items such as solar controllers often lack proper pressure plates for protecting the finely stranded wire..

These are AMP PIDG blade/tongue terminals that I use to avoid the screws directly impinging on the finely stranded wire:

Here's the indent on the blade/tongue created by the screw:

One can also use ferrules and a ferrule crimping tool.

Please be careful picking out crimp tools from Amazon, terminals too. Be sure what you are buying is from a reputable US company and let them do the sourcing ensuring QC. There are piles and piles of horrendous crimp tools on Amazon that make horrible crimps. There's also the aluminum crimp terminals (not tin plated copper) one of my customers got such a "killer deal" on..Ferrule crimpers are on sale At Amazon.com.

Last edited:

Similar threads

- Replies

- 18

- Views

- 724

- Replies

- 73

- Views

- 4K

- Replies

- 19

- Views

- 1K

- Replies

- 6

- Views

- 924

- Replies

- 16

- Views

- 2K

Latest posts

-

-

-

-

-

-

-

-

-

Fixing boats in Exotic Places - are new boats really that bad?

- Latest: HeadMistress