DHeckrotte

Guru

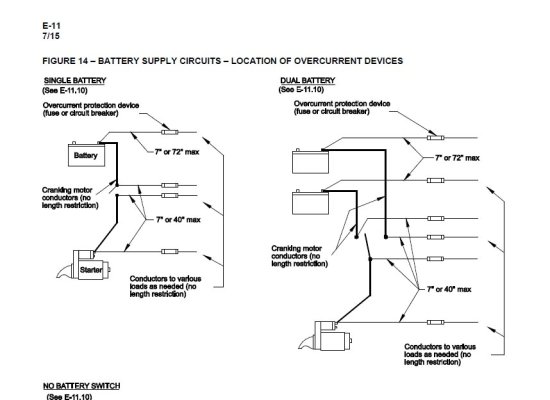

I've read all sorts of opinions about fusing batteries. ABYC requires fusing batteries for non-starting loads, but not on starting circuits (unless there's more lead on the boat than any of us have). Some folks recommend fusing all battery + wire at the battery. Some folks recommend fusing all battery + and - wire at the battery. Seems to me that I understand that fusing is sized to protect the wire. Even on house wiring, the fuses/breakers are sized to the circuit wire and not to the smaller stuff in devices and appliances. Battery wire is usually, it seems, way oversized for the loads despite the cost involved; presumably oversized for current losses in the cable.

Resultant questions: Fuse in accordance with ABYC? Fuse all battery + wire at the battery? Fuse all battery wire, + & -? Size fuses for the expected loads rather than oversized for the wire?

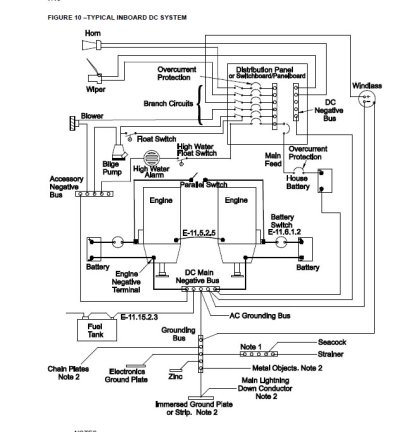

An inquiring mind wants to know: How come the seriously sized grounds (batt negatives) in the boat are not bonded to each other? Each engine is grounded by virtue of its own battery negative. The house side is similar in that the ground buss is connected to the house battery. The old/existing 110v battery charger connects all the battery negatives with a relatively small conductor. Blue Sea diagrams show an undefined 'ground' at each battery with the assumption that they are all 'ground'. Am I showing everybody why I failed 'Electricity and Magnetism' in first year Engineering?

I will be replacing all the 1/0 / 38 mm wire on the boat since I've found failed insulation on some of the 35 year old stuff. I'm adding ACRs and wiring battery switches correctly so that the engines will charge the house bank, will combine batts for low batt conditions, and isolate low batts. I will be adding at least the ABYC fusing.

And I ought to replace the wire to the anchor winch and add a breaker at a convenient place (rather than a switch at the head of the forward berth).

Resultant questions: Fuse in accordance with ABYC? Fuse all battery + wire at the battery? Fuse all battery wire, + & -? Size fuses for the expected loads rather than oversized for the wire?

An inquiring mind wants to know: How come the seriously sized grounds (batt negatives) in the boat are not bonded to each other? Each engine is grounded by virtue of its own battery negative. The house side is similar in that the ground buss is connected to the house battery. The old/existing 110v battery charger connects all the battery negatives with a relatively small conductor. Blue Sea diagrams show an undefined 'ground' at each battery with the assumption that they are all 'ground'. Am I showing everybody why I failed 'Electricity and Magnetism' in first year Engineering?

I will be replacing all the 1/0 / 38 mm wire on the boat since I've found failed insulation on some of the 35 year old stuff. I'm adding ACRs and wiring battery switches correctly so that the engines will charge the house bank, will combine batts for low batt conditions, and isolate low batts. I will be adding at least the ABYC fusing.

And I ought to replace the wire to the anchor winch and add a breaker at a convenient place (rather than a switch at the head of the forward berth).