waterfront

Veteran Member

- Joined

- Apr 18, 2012

- Messages

- 54

- Location

- USA

- Vessel Name

- Waterfront

- Vessel Make

- Chein Hwa Present Sundeck 35

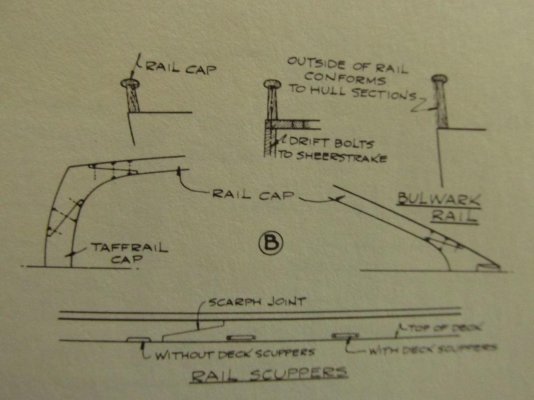

I have a scarf joint that has separated on my caprail. My thoughts are to clean out the material in the joint, refasten , and then fill with epoxy. After it sets up, sand and fair the area and then refinish. Are my thoughts correct or is there another method to make this repair?