You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New hard top

- Thread starter lipets

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

Comodave

Moderator Emeritus

- Joined

- Jul 2, 2015

- Messages

- 21,273

- Location

- Au Gres, MI

- Vessel Name

- Black Dog

- Vessel Make

- Formula 41PC

Looks nice, but looks like a lot of work. Keep us updated.

Sailor of Fortune

Guru

Looks nice, but looks like a lot of work. Keep us updated.

says the guy who is going to pull both engines for tank replacement,lol?

Comodave

Moderator Emeritus

- Joined

- Jul 2, 2015

- Messages

- 21,273

- Location

- Au Gres, MI

- Vessel Name

- Black Dog

- Vessel Make

- Formula 41PC

Only one engine and tank this winter, don’t want to overdo it.

FF

Guru

- Joined

- Oct 12, 2007

- Messages

- 22,552

IF built to walk on or use as a fly bridge , the 10x10 will be about 250-300 lbs depending on layup.

IF just a sun shade and solar carrier ,, it will still need help to getup in place.

An easy fun job , till the lifting starts.

IF just a sun shade and solar carrier ,, it will still need help to getup in place.

An easy fun job , till the lifting starts.

Sailor of Fortune

Guru

Made all the templates,

overall is 10x10

3 sheets 1/2" Nida core 4x8

Step one, cutout the contour of bridge deck to match the top with templates.

Next build a jig with the curve of top, then glass

How flexible is Nidacore? Do you have to make relief cuts to get it to bend to jig?

lipets

Senior Member

IF built to walk on or use as a fly bridge , the 10x10 will be about 250-300 lbs depending on layup.

IF just a sun shade and solar carrier ,, it will still need help to getup in place.

An easy fun job , till the lifting starts.

With the core the weight will be about 55 lbs.

to make it ez to handle & transport to boat it will be two sections

4x10 and 6x10

lipets

Senior Member

How flexible is Nidacore? Do you have to make relief cuts to get it to bend to jig?

It bends reasonably ok if you need to make a tight bend you can score it.

Incidentally the 4x8 sheets were $57 at boat builders supply

Sailor of Fortune

Guru

It bends reasonably ok if you need to make a tight bend you can score it.

Incidentally the 4x8 sheets were $57 at boat builders supply

Thats sounds really cheap, good for you! Are you going to use 1708 Mat once on the jig?

healhustler

Guru

- Joined

- Oct 2, 2009

- Messages

- 5,198

- Location

- USA

- Vessel Name

- Bucky

- Vessel Make

- Krogen Manatee 36 North Sea

Dang. At $57 per sheet, I might start thinking about extending my pilothouse again. I did my roof about 7 years ago, no issues since. It’s a worthwhile project, for sure.

Sailor of Fortune

Guru

Dang. At $57 per sheet, I might start thinking about extending my pilothouse again. I did my roof about 7 years ago, no issues since. It’s a worthwhile project, for sure.

prices have come down on composite sheets.I paid $51/sheet yesterday for 1/4" Marine plywood. I thought that was a good price. Keep in mind, composite still needs FG over it to be complete.

Of course, marine ply needs Fg over it too.

Last edited:

fractalphreak

Senior Member

- Joined

- Jun 23, 2018

- Messages

- 318

- Location

- United States

- Vessel Name

- Northwest Dream

- Vessel Make

- Davis Vashon 42 Trawler (Defever design)

Lipets,

Greetings! I am just about to embark on the very same project, almost the exact size. My tentative first glance is 10x14, looking to stay on the lighter side as our main purpose is a permanent weather cover and solar mount. Take and post lots of pics, and what materials quantities/cost you see. Would love to see how your methods work!

Greetings! I am just about to embark on the very same project, almost the exact size. My tentative first glance is 10x14, looking to stay on the lighter side as our main purpose is a permanent weather cover and solar mount. Take and post lots of pics, and what materials quantities/cost you see. Would love to see how your methods work!

Comodave

Moderator Emeritus

- Joined

- Jul 2, 2015

- Messages

- 21,273

- Location

- Au Gres, MI

- Vessel Name

- Black Dog

- Vessel Make

- Formula 41PC

We put a hardtotop hardtop on our present boat and a previous boat. I installed it in a day with a helper. We love it. It comes in panels about 2’ wide and you install it piece by piece on the bimini frame. On this boat the hardtop is pretty big so I had to have 1 1/4” s/s bows made to support the top. It came in a box about 14’ long and I could pick it up.

Attachments

Comodave

Moderator Emeritus

- Joined

- Jul 2, 2015

- Messages

- 21,273

- Location

- Au Gres, MI

- Vessel Name

- Black Dog

- Vessel Make

- Formula 41PC

The cost of the hardtop was about $2000.

lipets

Senior Member

Thats sounds really cheap, good for you! Are you going to use 1708 Mat once on the jig?

Don't need mat with Nida, it already has mat type finish.

lipets

Senior Member

Lipets,

Greetings! I am just about to embark on the very same project, almost the exact size. My tentative first glance is 10x14, looking to stay on the lighter side as our main purpose is a permanent weather cover and solar mount. Take and post lots of pics, and what materials quantities/cost you see. Would love to see how your methods work!

4 gal resin about $80 ea

16 yards 17oz biax cloth, brushes, rollers, squeegees etc $200

from US Composites

1/2 sheet 1/2" ply for jig, cut on band saw this morning

1 sheet xps foam insulation used to build up edges $20

So about $620 so far.

this will be offset if I sell the current frame & bimini

Now anything yuo build related to solar is tax exempt plus a tax rebate

lipets

Senior Member

We put a hardtotop hardtop on our present boat and a previous boat.... . It comes in panels about 2’ wide and you install it piece by piece on the bimini frame. .

I looked at that system, didn't appeal to me

There's one boat in my marina missing one which went flying in a storm

Comodave

Moderator Emeritus

- Joined

- Jul 2, 2015

- Messages

- 21,273

- Location

- Au Gres, MI

- Vessel Name

- Black Dog

- Vessel Make

- Formula 41PC

Ours has been through 60+ mph winds.

IF built to walk on or use as a fly bridge , the 10x10 will be about 250-300 lbs depending on layup.

IF just a sun shade and solar carrier ,, it will still need help to getup in place.

An easy fun job , till the lifting starts.

11' wide X13' long , 5/8" corecell. 3 layers of 6oz. mat on top. one layer on bottom 60lbs.

Attachments

Aft Deck Capt

Senior Member

- Joined

- May 18, 2014

- Messages

- 191

- Location

- US

- Vessel Name

- Long Shot

- Vessel Make

- 1978 Californian 42' LRC

A timely thread that I'll be watching closely!

I really like the translucent 8mm material that "Hard to Top" utilizes but desire to build a FG & foam frame that is anchored to the FB floor vs the FB teak rails like the existing bimini frame.

Up till now it's been difficult to find the 8mm material in lengths over 8'. A construction contact is going to let me piggy back an order of the same material form their supplier up to 16'.

Lipets looking forward to your pics.

I really like the translucent 8mm material that "Hard to Top" utilizes but desire to build a FG & foam frame that is anchored to the FB floor vs the FB teak rails like the existing bimini frame.

Up till now it's been difficult to find the 8mm material in lengths over 8'. A construction contact is going to let me piggy back an order of the same material form their supplier up to 16'.

Lipets looking forward to your pics.

BruceK

Moderator Emeritus

- Joined

- Oct 31, 2011

- Messages

- 13,347

- Vessel Name

- Sojourn

- Vessel Make

- Integrity 386

What are they made of? Something translucent by the look of it. Been there long? All panels still present and correct?We put a hardtotop hardtop on our present boat and a previous boat. I installed it in a day with a helper. We love it. It comes in panels about 2’ wide and you install it piece by piece on the bimini frame. On this boat the hardtop is pretty big so I had to have 1 1/4” s/s bows made to support the top. It came in a box about 14’ long and I could pick it up.

Comodave

Moderator Emeritus

- Joined

- Jul 2, 2015

- Messages

- 21,273

- Location

- Au Gres, MI

- Vessel Name

- Black Dog

- Vessel Make

- Formula 41PC

They are some type of polycarbonate panel. They are white but light comes through pretty well. They have an aluminum extrusion on the sides. You take your bimini frame and get the tops in a line horizontally so the panels will lay on the frame fore and aft. Then you take stainless steel clamps and screw the clamps around the bimini frame and through the aluminum extrusions. My first one was on a Trojan F32 and wasn’t as large as the current one. I went with the cheaper version that had a vinyl edging around it. Since the one for my President is so much larger I had to go with the upgraded version that has an aluminum extrusion around the edges. I had 1” bimini bows on both boats, they worked fine with the smaller top on the Trojan. On the President with the way larger top the 1” bows were not strong enough, in my opinion, so I had 4 bows made out of 1.25” stainless. The top is rock solid now. The boat has been tied up to my dock here at the house in over 60 mph winds and I have had no problems at all except me worrying about it during the winds. Now I just check the dock lines and really don’t give the top a thought. The company is a rather small business and don’t reply as quickly as I would like but it is what it is. Both times I bought the tops I drove to their shop and picked them up since they are located here in Michigan. I may mount some solar panels on the top and the hardtop over my sundeck but don’t really need them at this time since we are only doing local cruising at this time. Overall I like the tops or I would not have bought the sexond one. They are easy to install and are warranted for 10 years. No affiliation just a happy customer.

Aft Deck Capt

Senior Member

- Joined

- May 18, 2014

- Messages

- 191

- Location

- US

- Vessel Name

- Long Shot

- Vessel Make

- 1978 Californian 42' LRC

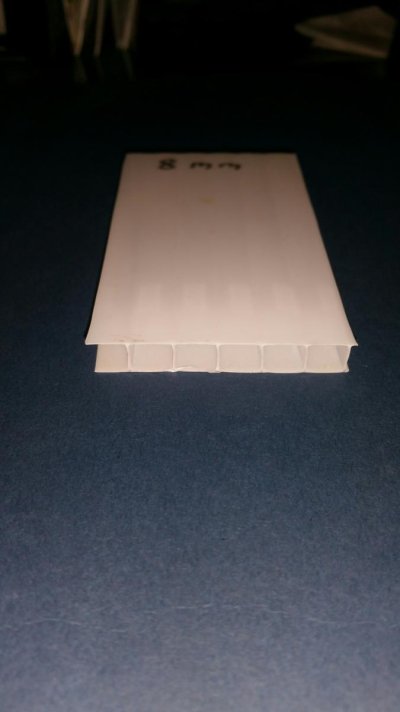

This is a cross section of some 8mm translucent polycarbonate. It's very stiff longitudinally but can be pulled into a soft arc side to side.

Basically the same material that is utilized in the construction of greenhouse wall and roof panels.

Basically the same material that is utilized in the construction of greenhouse wall and roof panels.

Attachments

Last edited:

Comodave

Moderator Emeritus

- Joined

- Jul 2, 2015

- Messages

- 21,273

- Location

- Au Gres, MI

- Vessel Name

- Black Dog

- Vessel Make

- Formula 41PC

Yes, that is similar to the tops. You measure the arc of the bimini and they bend the aluminum edge trim to match the curve. They also bend keder strips to match the curve. The keder strips make it easy to fabricate side curtains.

They are some type of polycarbonate panel. They are white but light comes through pretty well. They have an aluminum extrusion on the sides. You take your bimini frame and get the tops in a line horizontally so the panels will lay on the frame fore and aft. Then you take stainless steel clamps and screw the clamps around the bimini frame and through the aluminum extrusions. My first one was on a Trojan F32 and wasn’t as large as the current one. I went with the cheaper version that had a vinyl edging around it. Since the one for my President is so much larger I had to go with the upgraded version that has an aluminum extrusion around the edges. I had 1” bimini bows on both boats, they worked fine with the smaller top on the Trojan. On the President with the way larger top the 1” bows were not strong enough, in my opinion, so I had 4 bows made out of 1.25” stainless. The top is rock solid now. The boat has been tied up to my dock here at the house in over 60 mph winds and I have had no problems at all except me worrying about it during the winds. Now I just check the dock lines and really don’t give the top a thought. The company is a rather small business and don’t reply as quickly as I would like but it is what it is. Both times I bought the tops I drove to their shop and picked them up since they are located here in Michigan. I may mount some solar panels on the top and the hardtop over my sundeck but don’t really need them at this time since we are only doing local cruising at this time. Overall I like the tops or I would not have bought the sexond one. They are easy to install and are warranted for 10 years. No affiliation just a happy customer.

Comodave,

Thx for the write up. I've been looking at them but the translucent material bothers me. Seems like it would be hot in the summer sun and don't understand why a opaque material wouldn't be available. Suppose I could paint it with a opaque white on the top. I don't want ANY light coming thru if possilbe. Comments?

Also, is there a way to put a door in the top to access the upper side for installing solar panels? Seems like it would be pretty hard without some sort of access.

However, love the simplicity and light weight.

11' wide X13' long , 5/8" corecell. 3 layers of 6oz. mat on top. one layer on bottom 60lbs.

Boatpoker,

Tell us more, sounds good. 60lbs for the whole thing?

What is the corecell? Is that like nidacore? Supplier?

Thanks much!

lipets

Senior Member

next step went to HD bought XPS insulation, used skill saw to cut a 45, I think a table saw would have been better.

I made 3" wide strips to build up the edges, didn't want to look a thin wafer and after glassing will add strength.

the hard edges will be shaved with razor after the caulking drys and tape removed.

also the edges will be cleaned up to uniform before glassing

since the front and back will have a curve I'll do those after glassing

I made 3" wide strips to build up the edges, didn't want to look a thin wafer and after glassing will add strength.

the hard edges will be shaved with razor after the caulking drys and tape removed.

also the edges will be cleaned up to uniform before glassing

since the front and back will have a curve I'll do those after glassing

Attachments

Similar threads

- Replies

- 15

- Views

- 3K