You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

New hard top

- Thread starter lipets

- Start date

The friendliest place on the web for anyone who enjoys boating.

If you have answers, please help by responding to the unanswered posts.

If you have answers, please help by responding to the unanswered posts.

Aft Deck Capt

Senior Member

- Joined

- May 18, 2014

- Messages

- 191

- Location

- US

- Vessel Name

- Long Shot

- Vessel Make

- 1978 Californian 42' LRC

Agreed, looks like a graceful arc.

My FG experience is limited to glassing over a shaped foam build assembly, similar to surfboard construction. Do you anticipate any spring back or does the underside glass hold the core pretty true to the form when it's flipped for glassing the topside in this type of construction? All new to me.

BTW, nice shop floor!

My FG experience is limited to glassing over a shaped foam build assembly, similar to surfboard construction. Do you anticipate any spring back or does the underside glass hold the core pretty true to the form when it's flipped for glassing the topside in this type of construction? All new to me.

BTW, nice shop floor!

lipets

Senior Member

Haven't glassed yet but my understanding is the layer of 17oz on one side should make it pretty solid.

Also the foam on the edge made it stiffer on that side of the panel.

Due to the overall size I'm building it two sections 4x10 & 6x10, no way to transport or for that matter handle it in one piece.

Trying to come up with a way to splice the two halves together on the boat, some of that planning goes to how stiff it is with 17oz on both sides.

Also the foam on the edge made it stiffer on that side of the panel.

Due to the overall size I'm building it two sections 4x10 & 6x10, no way to transport or for that matter handle it in one piece.

Trying to come up with a way to splice the two halves together on the boat, some of that planning goes to how stiff it is with 17oz on both sides.

lipets

Senior Member

lipets

Senior Member

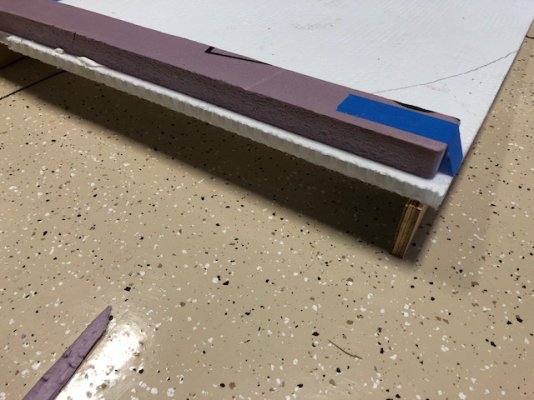

the under side is glassed just place temp forms in to flip and glass side two

the pink foam is a 1x2.5" glassed to edge as a reveal to make it look like thicker edge (it's only 1/2" otherwise)

THe glass cloth came out very nice and even

the top is split into two halves 4x10 and 6x10

three sides glassed now used 1.5 G MAS epoxy, no smell.

the pink foam is a 1x2.5" glassed to edge as a reveal to make it look like thicker edge (it's only 1/2" otherwise)

THe glass cloth came out very nice and even

the top is split into two halves 4x10 and 6x10

three sides glassed now used 1.5 G MAS epoxy, no smell.

Attachments

Last edited:

lipets

Senior Member

I was planning on bolting on the two arch sides place and two SS supports up front then man handling them up and attaching two halves on board.

Not happening this is to big, now going to bring it to local yard join two halves on some stands, mount the three solar panels.

Have fork lift or small crane hoist it up, not heavy, the top is about 50-60 lbs glassed, the panels are 38lbs each

it just to bulky to handle and don't want anyone hurt.

Not happening this is to big, now going to bring it to local yard join two halves on some stands, mount the three solar panels.

Have fork lift or small crane hoist it up, not heavy, the top is about 50-60 lbs glassed, the panels are 38lbs each

it just to bulky to handle and don't want anyone hurt.

db2

Veteran Member

Interesting write up, thanks for your effort. I wish the prior owner of my boat had better integrated the shape of the hard top to the boat. BTW if you would like to save a lot of money on epoxy try Aeromarine on line. They mail order and I find the quality to be as good as the expensive name brands. It is a 2 to 1 mix which keeps things simple.

RT Firefly

Enigma

Greetings,

Mr. l. Very nice! One added advantage of MAS epoxy is there is no ketone blush like with West System. Good move to have the yard hoist it into place. One gust of wind at the wrong time and.....

Mr. l. Very nice! One added advantage of MAS epoxy is there is no ketone blush like with West System. Good move to have the yard hoist it into place. One gust of wind at the wrong time and.....

lipets

Senior Member

The core is not intended to used on edge, very little strength I was told.

So his side frames are only the structural fiberglass not getting benefit from the core, plywood is the preferred materiel.

Bondo's usually have talc in them and absorb moisture

So his side frames are only the structural fiberglass not getting benefit from the core, plywood is the preferred materiel.

Bondo's usually have talc in them and absorb moisture

lipets

Senior Member

here's the 3/4 ply support often seen as radar arch sides.

pre-wet the plywood with resin before glassing with 10oz

here's dry fit onboard, can't believe it fit first try

I matched the slope of the front of the bridge.

The front will have two 1-1/4" SS vertical supports

Back to my shop to prime & paint now.

Attachments

Sailor of Fortune

Guru

going to look good,nice work!

Dougcole

Guru

Similar project on youtube

Project Atticus is an awesome channel. Y'all should check it out.

Similar threads

- Replies

- 15

- Views

- 3K