Westiculo

Senior Member

- Joined

- Feb 27, 2017

- Messages

- 271

- Location

- US

- Vessel Name

- Rose Mary

- Vessel Make

- 42 Grand Banks Motoryacht - 1985

I'm trying a different method for mounting my rails.

My varnish had gone to **** and water had rotted the wood at most screws holding the rails on and the stanchions to the cap rail.

I want to avoid all rot and I never want to do this again. See what you think of my approach.

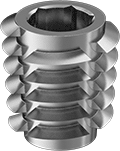

I over-drilled the screw holes with a large size bit and filled the hole with thickened epoxy. Drilled again and threaded in a stainless helicoil with a bit of epoxy. I ordered some sealing washers from mcmaster that have a bit of neoprene rubber on the back side (see photos). I am mounting these washers between the stanchion and the wood with no other sealant/caulk/butyl.

I feel like a genius! No caulk or butyl mess, the stanchions no longer ding up the teak which lets moisture in to ruin the varnish job, and even if a tiny bit of water gets in the screw holes, they are impervious due to the epoxy. Most importantly - my rails are rock solid. The only downfall is it took 2 full days to make it happen.

What did I overlook?? Will it work?

My varnish had gone to **** and water had rotted the wood at most screws holding the rails on and the stanchions to the cap rail.

I want to avoid all rot and I never want to do this again. See what you think of my approach.

I over-drilled the screw holes with a large size bit and filled the hole with thickened epoxy. Drilled again and threaded in a stainless helicoil with a bit of epoxy. I ordered some sealing washers from mcmaster that have a bit of neoprene rubber on the back side (see photos). I am mounting these washers between the stanchion and the wood with no other sealant/caulk/butyl.

I feel like a genius! No caulk or butyl mess, the stanchions no longer ding up the teak which lets moisture in to ruin the varnish job, and even if a tiny bit of water gets in the screw holes, they are impervious due to the epoxy. Most importantly - my rails are rock solid. The only downfall is it took 2 full days to make it happen.

What did I overlook?? Will it work?