angus99

Guru

I’ve started the dreaded job of removing decades of varnish from the rails of our boat.

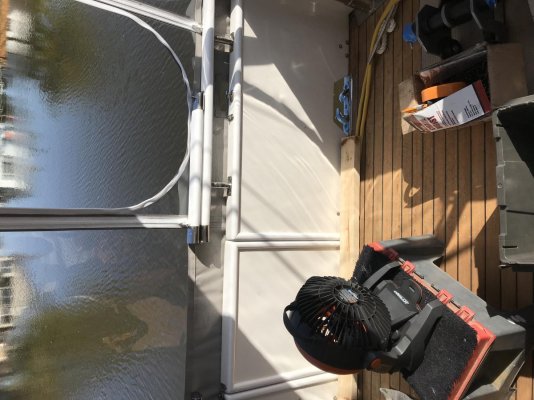

First issue: I’m using a heat gun, which is getting most of the old fnish off. However, on the aft rail—which I assume was most-often in the sun—I’m only able to get the upper layers off with the heat gun. There’s a base layer that heat and paint strippers, by themselves, won’t touch. The only thing that’s had any effect is copious amounts of stripper, followed by wiping it down to remove flammability, followed by a heat gun. Even then, I still don’t get down to bare wood, but am left with a gummy layer (first photo). So, I’m guessing my only option is sanding it off. (80-grit, followed by 150 and 220)

Second issue: Even where the heat gun is working well, there are still other places where some of the original finish is visible after sanding with 80 grit. (Second photo).

I’m going to go back with Cetol Natural Teak followed by Cetol Gloss—I do not want to use varnish. Cetol tech support says their finish will only stick to bare wood. They recommend against penetrating epoxy or any other barrier coat.

For those using Cetol, is it really necessary to strip down to perfectly bare wood? If so, it looks like I’ll need to use 60-grit to get all the finish off and remove a fair amount of wood in the process.

If any of you faced similar issues, I’d appreciate knowing how you handled them.

First issue: I’m using a heat gun, which is getting most of the old fnish off. However, on the aft rail—which I assume was most-often in the sun—I’m only able to get the upper layers off with the heat gun. There’s a base layer that heat and paint strippers, by themselves, won’t touch. The only thing that’s had any effect is copious amounts of stripper, followed by wiping it down to remove flammability, followed by a heat gun. Even then, I still don’t get down to bare wood, but am left with a gummy layer (first photo). So, I’m guessing my only option is sanding it off. (80-grit, followed by 150 and 220)

Second issue: Even where the heat gun is working well, there are still other places where some of the original finish is visible after sanding with 80 grit. (Second photo).

I’m going to go back with Cetol Natural Teak followed by Cetol Gloss—I do not want to use varnish. Cetol tech support says their finish will only stick to bare wood. They recommend against penetrating epoxy or any other barrier coat.

For those using Cetol, is it really necessary to strip down to perfectly bare wood? If so, it looks like I’ll need to use 60-grit to get all the finish off and remove a fair amount of wood in the process.

If any of you faced similar issues, I’d appreciate knowing how you handled them.

![220px-Sharpening_of_card_scraper[1].jpg](/data/attachments/86/86223-8f7853d460800a3901dbb78c8bc44309.jpg)