Nomad Willy

Guru

I suspect that CapBill is right and it probably is just fly shxit. With certain types of hoses it may be applicable though. But if you want to keep a hose connection from leaking you wouldn't use a clamp like a "U" bolt and most clamps on cars and boats aren't entirely unlike a "U" bolt.

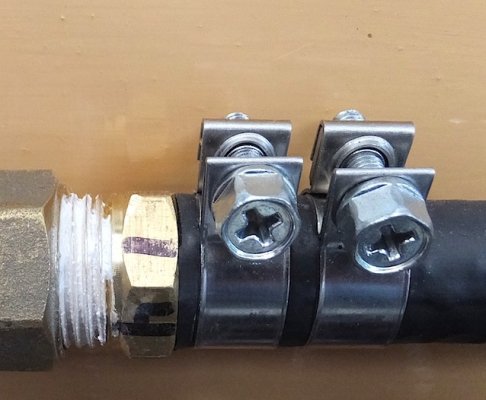

Re the super duper high grade "the best that money can buy" is usually silly, a waste of money, not cost effective and perhaps even pretentious. The slotted band clamps are indeed questionable in strength and could sink one's boat. But if not overtightened and replaced often enough so rust is not an issue they are probably fully serviceable within those stated limits. Mine must be SS (except the little guys in my pic) as I don't see any of them rusting, or rusting enough to be an issue. Good enough is .... good enough.

Re the super duper high grade "the best that money can buy" is usually silly, a waste of money, not cost effective and perhaps even pretentious. The slotted band clamps are indeed questionable in strength and could sink one's boat. But if not overtightened and replaced often enough so rust is not an issue they are probably fully serviceable within those stated limits. Mine must be SS (except the little guys in my pic) as I don't see any of them rusting, or rusting enough to be an issue. Good enough is .... good enough.

Scary actually.

Scary actually.