AKDoug

Guru

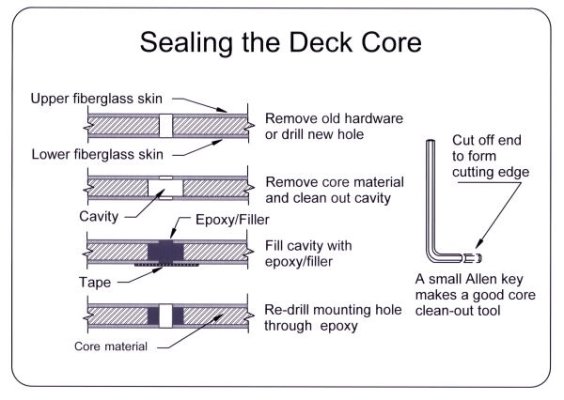

I am in process of tearing off the old teak boxes and replacing them with fiberglass ones, finding a half dozen small screw holes into the cored deck under each box. I am seeking the best way to fill them and seal the core, being inclined to simply drill the holes out oversized and then fill with epoxy.

I believe the holes will all be under the new boxes (different shape and different size) so color doesn't matter. I am also inclined to drill the new mounting holes oversized and fill them with epoxy before mounting the new boxes (3 screws) so the screws go into epoxy. Will the epoxy tolerate that or will the screws going in crack it?

I believe the holes will all be under the new boxes (different shape and different size) so color doesn't matter. I am also inclined to drill the new mounting holes oversized and fill them with epoxy before mounting the new boxes (3 screws) so the screws go into epoxy. Will the epoxy tolerate that or will the screws going in crack it?