- Joined

- Apr 15, 2008

- Messages

- 13,731

- Location

- California Delta

- Vessel Name

- FlyWright

- Vessel Make

- 1977 Marshall Californian 34 LRC

Four years ago, I had fuel contamination due to a failed fuel cap that resulted in a stbd engine shutdown on a cruise. The diagnosis and repair were documented on this thread. These aluminum tanks are 12 years old and were installed by the PO.

A couple months ago, I detected some fuel seeping through the bottom of the stbd tank. I was surprised since it had only been 4 years since the tanks were scrubbed and the fuel polished professionally. Here's what I saw on the external bottom of the tank.

At the time of the polishing, I had an inspection plate installed in the center section of the fuel tank with one tank baffle fwd and one baffle aft. This leak was located aft of the aft baffle so a new inspection plate was needed to access the area for repair. I transferred the stbd fuel into the port tank in preparation for the repair using a small transfer pump plumbed to a fuel hose which I temporarily installed between the tank outlets.

I called Duke of Cruising Seas for the job since he had done the prior work. He installed a 2nd inspection plate in the stbd fuel tank. This gave me complete access to the aft 2/3 of the stbd tank. The aft section had a fair amount of bacterial growth which had caused crevice corrosion in several small spots on the bottom in an area roughly 10 inches diameter. This area was near the center of the section and not along the edges or corners. The middle and fwd sections were relatively clean with no apparent crevices.

With my cellphone camera, I was able to photograph the as-found condition of the tank after cleaning the bottom growth. This cleaning was done with an aluminum straight edge scraper, lots of fuel absorbent pads, sandpaper, Scotchbrite pads, acetone and a shop vac. By the time I was done, I could have eaten off the fuel tank bottom.

Here's a closeup of the largest pits

The mid section of the tank:

I knew that my tanks were not threatened with a structural failure as one might have with 30 year old rusty tanks and just needed to have the bottom sealed to prevent further leakage. I was familiar with a product called ProSeal that has been used in the aviation industry for Avgas and Jet Fuel tank sealing and thought it might be a good candidate for this repair.

I should add that I would not recommend this method of repair for any tanks that are at risk of structural failure.

I consulted with my favorite aviation mechanics and an amateur airplane builder who have years of experience using ProSeal. I found that Van's Aircraft had switched over from using ProSeal to a product called Flamemaster but it's the same spec and for all practical purposes, an identical product. I purchased a quart can of Flamemaster from Van's Aircraft for about $50. I used the B2 version which allows 2 hrs of working time and requires 72 hrs of cure time.

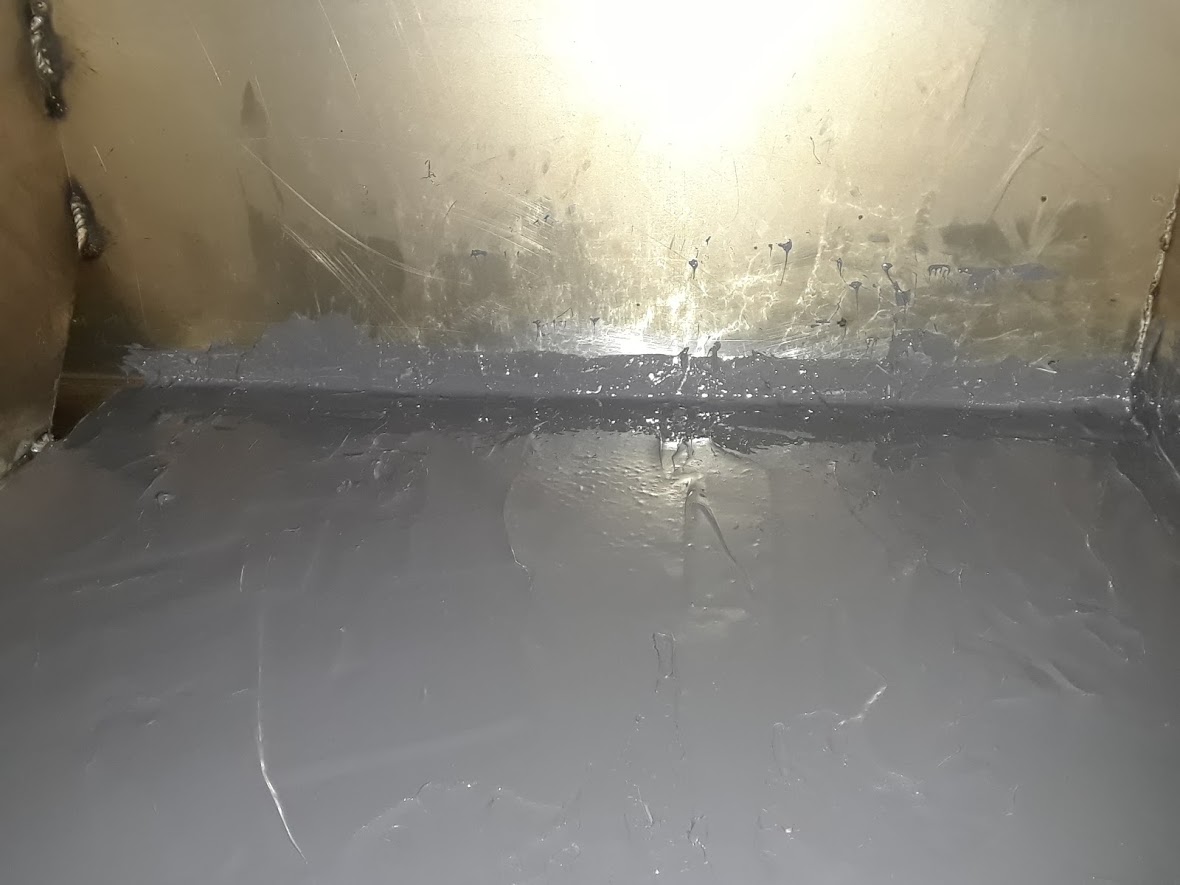

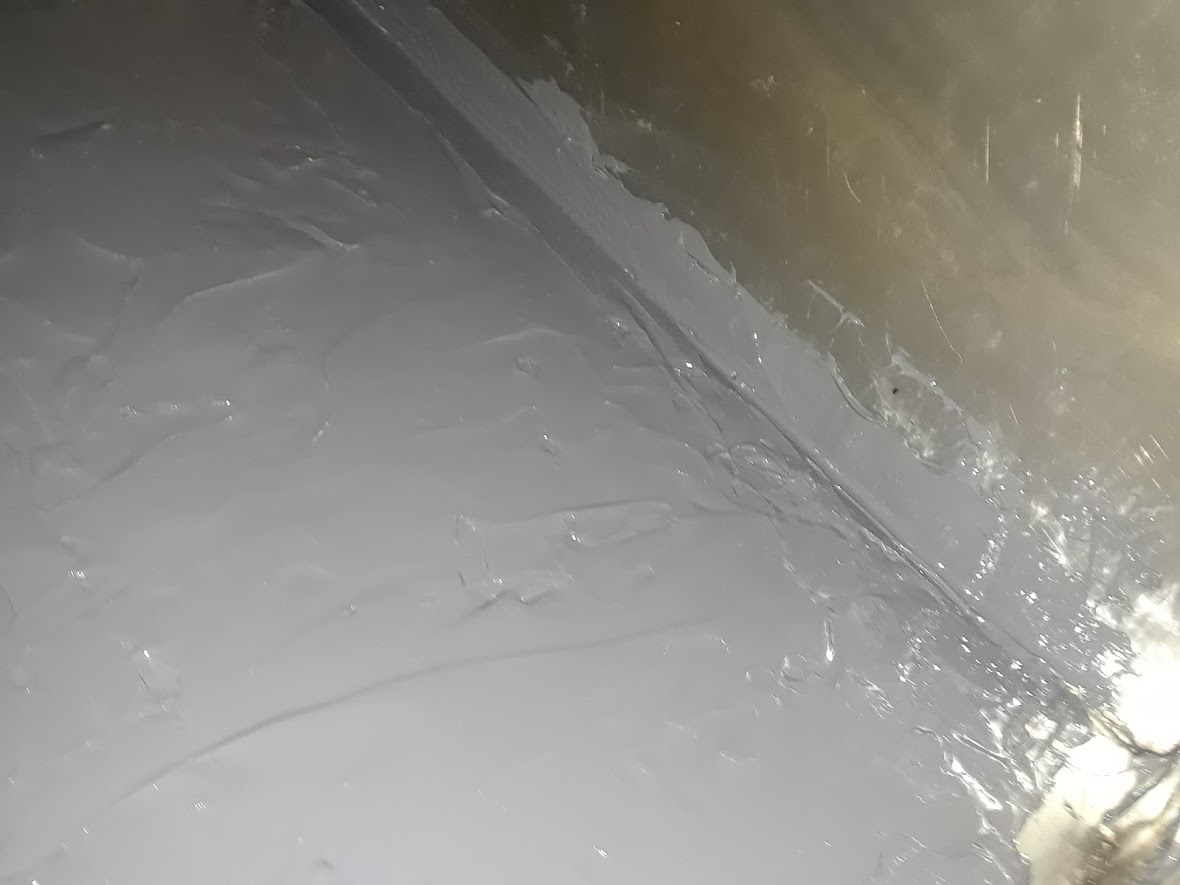

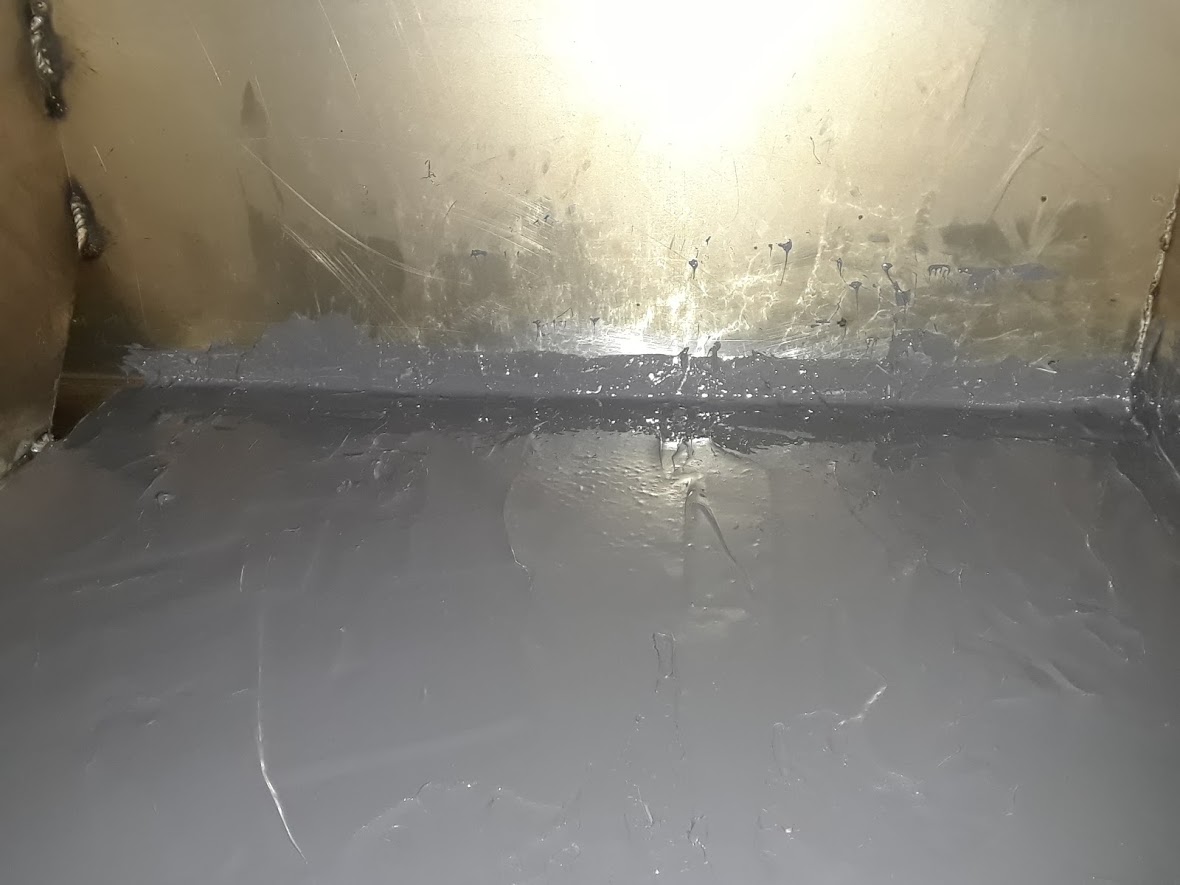

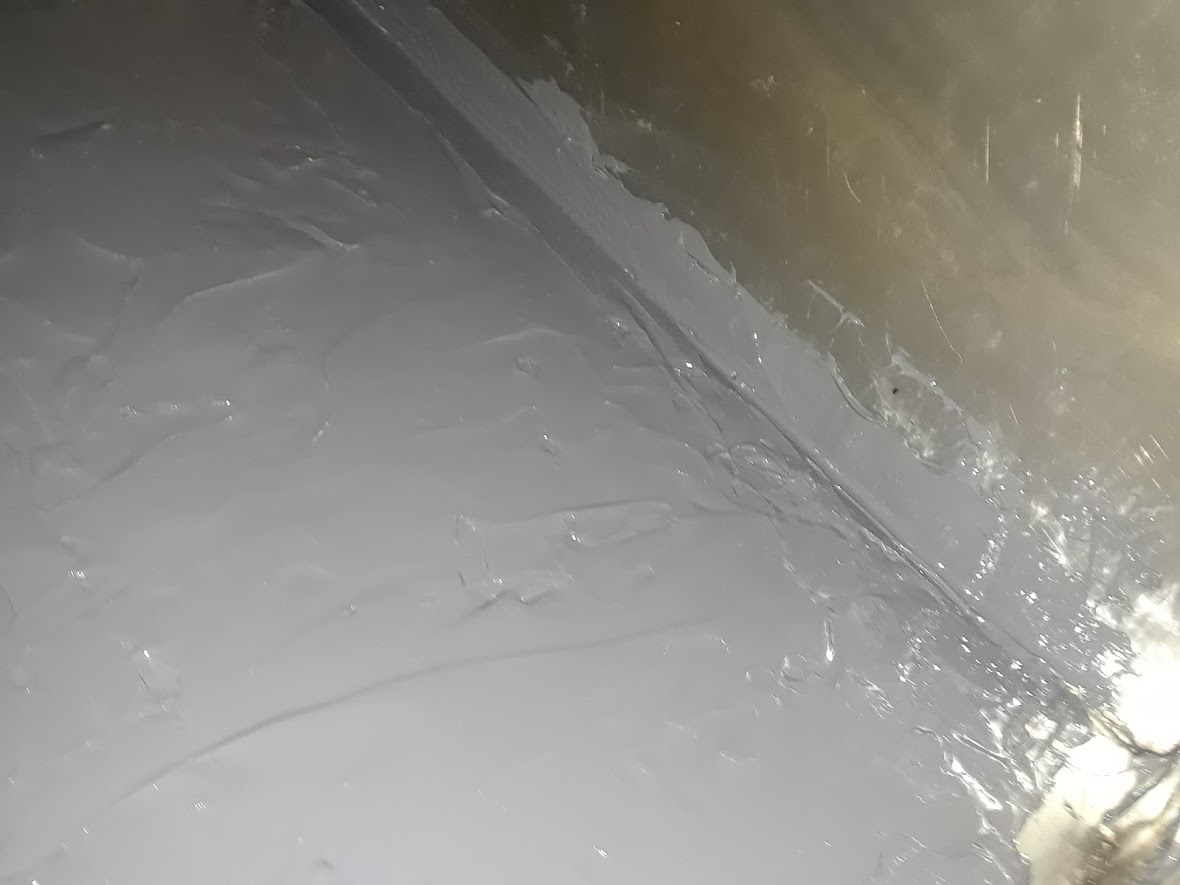

After thoroughly mixing the 2-part sealant, I buttered the sealant onto the tank floor and continued 1.5-2 inches up the tank sides. The following pics show the work in progress as I was applying the sealant. I'd work an area, sometimes in the blind, then take cell photos to confirm proper coverage. Then I'd go back and fill in areas until the coverage was complete. The ripples shown in these photos smoothed out through the application and curing processes.

One thing I was warned about with this sealant is that it sticks to ANYTHING it touches. I started out with plenty of rubber gloves at my disposal which got discarded regularly. I was careful about the tools I'd use since they were probably going to get tossed after the job.

I rigged a plastic applicator to the end of a short broomstick handle that worked perfectly to reach the deepest corners and edges. Other disposable applicators were also used to butter the corners and tank sides.

I let the tank sit empty to cure for over a week. When I returned to the boat, the sealant was smooth and hard. I installed a sight tube onto the stbd tank and transferred the fuel back from port to stbd. I also installed new primer pumps and wired them to SPST switches at the Racor panel to aid in priming the system.

I'm still sitting with 1/4 tanks and there is no signs of leakage. My stbd-only sight tube is a big plus since both tanks have always remained within 2 gallons on refill of 100 gals each side. Someday I might add one to the port side, but it's somewhat redundant in my vessel without a genset feeding from one tank and no permanent crossfeed/transfer capability.

I hope this helps some others who are dealing with non-structural leaks from their fuel tanks. I think this product is a huge step forward in repairing tanks rather than replacing them at huge expense.

Incidentally, my total cost was around $500 with the new inspection plate, sealant and supplies.

A couple months ago, I detected some fuel seeping through the bottom of the stbd tank. I was surprised since it had only been 4 years since the tanks were scrubbed and the fuel polished professionally. Here's what I saw on the external bottom of the tank.

At the time of the polishing, I had an inspection plate installed in the center section of the fuel tank with one tank baffle fwd and one baffle aft. This leak was located aft of the aft baffle so a new inspection plate was needed to access the area for repair. I transferred the stbd fuel into the port tank in preparation for the repair using a small transfer pump plumbed to a fuel hose which I temporarily installed between the tank outlets.

I called Duke of Cruising Seas for the job since he had done the prior work. He installed a 2nd inspection plate in the stbd fuel tank. This gave me complete access to the aft 2/3 of the stbd tank. The aft section had a fair amount of bacterial growth which had caused crevice corrosion in several small spots on the bottom in an area roughly 10 inches diameter. This area was near the center of the section and not along the edges or corners. The middle and fwd sections were relatively clean with no apparent crevices.

With my cellphone camera, I was able to photograph the as-found condition of the tank after cleaning the bottom growth. This cleaning was done with an aluminum straight edge scraper, lots of fuel absorbent pads, sandpaper, Scotchbrite pads, acetone and a shop vac. By the time I was done, I could have eaten off the fuel tank bottom.

Here's a closeup of the largest pits

The mid section of the tank:

I knew that my tanks were not threatened with a structural failure as one might have with 30 year old rusty tanks and just needed to have the bottom sealed to prevent further leakage. I was familiar with a product called ProSeal that has been used in the aviation industry for Avgas and Jet Fuel tank sealing and thought it might be a good candidate for this repair.

I should add that I would not recommend this method of repair for any tanks that are at risk of structural failure.

I consulted with my favorite aviation mechanics and an amateur airplane builder who have years of experience using ProSeal. I found that Van's Aircraft had switched over from using ProSeal to a product called Flamemaster but it's the same spec and for all practical purposes, an identical product. I purchased a quart can of Flamemaster from Van's Aircraft for about $50. I used the B2 version which allows 2 hrs of working time and requires 72 hrs of cure time.

After thoroughly mixing the 2-part sealant, I buttered the sealant onto the tank floor and continued 1.5-2 inches up the tank sides. The following pics show the work in progress as I was applying the sealant. I'd work an area, sometimes in the blind, then take cell photos to confirm proper coverage. Then I'd go back and fill in areas until the coverage was complete. The ripples shown in these photos smoothed out through the application and curing processes.

One thing I was warned about with this sealant is that it sticks to ANYTHING it touches. I started out with plenty of rubber gloves at my disposal which got discarded regularly. I was careful about the tools I'd use since they were probably going to get tossed after the job.

I rigged a plastic applicator to the end of a short broomstick handle that worked perfectly to reach the deepest corners and edges. Other disposable applicators were also used to butter the corners and tank sides.

I let the tank sit empty to cure for over a week. When I returned to the boat, the sealant was smooth and hard. I installed a sight tube onto the stbd tank and transferred the fuel back from port to stbd. I also installed new primer pumps and wired them to SPST switches at the Racor panel to aid in priming the system.

I'm still sitting with 1/4 tanks and there is no signs of leakage. My stbd-only sight tube is a big plus since both tanks have always remained within 2 gallons on refill of 100 gals each side. Someday I might add one to the port side, but it's somewhat redundant in my vessel without a genset feeding from one tank and no permanent crossfeed/transfer capability.

I hope this helps some others who are dealing with non-structural leaks from their fuel tanks. I think this product is a huge step forward in repairing tanks rather than replacing them at huge expense.

Incidentally, my total cost was around $500 with the new inspection plate, sealant and supplies.

Last edited: