Shoalwaters

Guru

- Joined

- Feb 24, 2008

- Messages

- 681

- Location

- St. Lucia, West Indies

- Vessel Name

- "Dragon Lady"

- Vessel Make

- DeFever 41

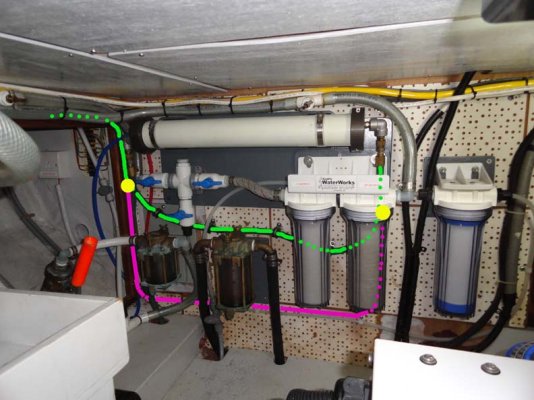

Yesterday, while changing the sediment filters on my watermaker, I noticed that the green high-pressure hose (arrows) had been chafing against the back (in other words the part you can't see!) of filter housing "B" and had nearly worn all the way through the housing. I have added an extra cushion-clamp to prevent the hose from touching the filter housing. However, the root of the problem is still there: the green hose vibrates significantly when the hi-pressure pump is running despite the 4 cushion clamps holding it to the bulkhead. It is only be a matter of time before the the hose starts to wear where it passes through the clamps. Any ideas?

BTW: The hose in question is the hi-pressure supply to the membrane. The vibration is very fast and seems to be side-to-side, not axial. The hi-pressure return hose to the control valve does not vibrate.

BTW: The hose in question is the hi-pressure supply to the membrane. The vibration is very fast and seems to be side-to-side, not axial. The hi-pressure return hose to the control valve does not vibrate.

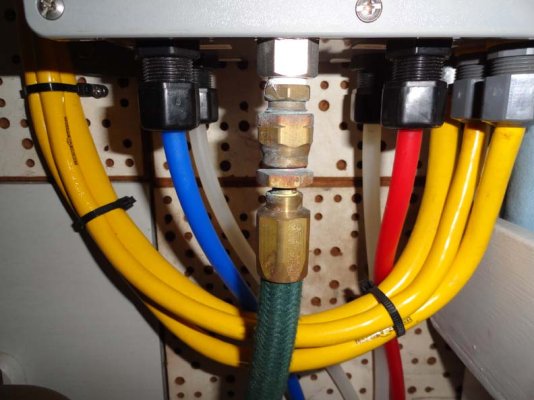

when I planned the installation, so I put the end of the membrane with the most connections (3) nearest to where they had to go.

when I planned the installation, so I put the end of the membrane with the most connections (3) nearest to where they had to go.

Very professional job and well done.

Very professional job and well done.