hmason

Guru

- Joined

- Aug 9, 2013

- Messages

- 2,764

- Location

- USA

- Vessel Name

- Lucky Lucky

- Vessel Make

- Pacific Mariner 65

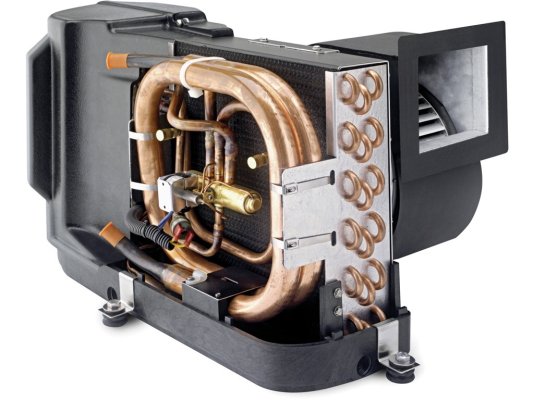

Had the reverse cycle heat on last night. 3 units running. This morning one unit had tripped its breaker and shutdown. Turned it back on and it tripped the breaker again. I let it sit for an hour and tried again. This time it displayed an error code that is defined as "high current." It attempted to restart and then ran just fine.

Does anyone know the meaning of "high current?" Should I be concerned or keep running it?

Thanks all.

Does anyone know the meaning of "high current?" Should I be concerned or keep running it?

Thanks all.