janice142

Guru

- Joined

- Oct 12, 2011

- Messages

- 1,239

- Location

- USofA

- Vessel Name

- Seaweed

- Vessel Make

- Schucker mini-trawler

I'm in a dispute and need some back-up, or to eat crow.

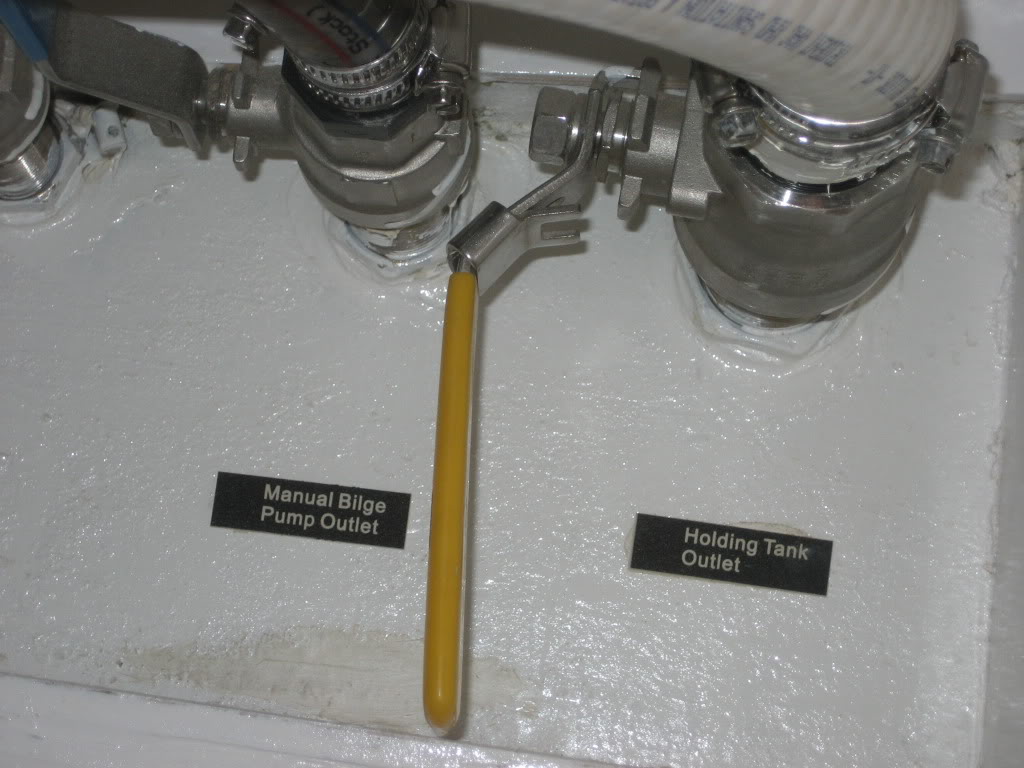

Under the waterline all hoses have two hose clamps. I was taught and always put one on in one direction, and the other, the opposite way around. I don't know why except Daddy did it that way on our boat.

Yesterday afternoon I was told that as long as two where there, they didn't have to be on in opposite directions. "It's the same" and I'm being too particular. Well, that's not the exact word used, but you get my drift.

On your boat, below the waterline or where ever you have two hose clamps side by side, are they run in the same direction or not?

[And should I eat crow, or can you provide me with a why you do it my way -- which I happen to think is correct!]

Thanks.

Under the waterline all hoses have two hose clamps. I was taught and always put one on in one direction, and the other, the opposite way around. I don't know why except Daddy did it that way on our boat.

Yesterday afternoon I was told that as long as two where there, they didn't have to be on in opposite directions. "It's the same" and I'm being too particular. Well, that's not the exact word used, but you get my drift.

On your boat, below the waterline or where ever you have two hose clamps side by side, are they run in the same direction or not?

[And should I eat crow, or can you provide me with a why you do it my way -- which I happen to think is correct!]

Thanks.