Hmmm, open either? Weather strip for temperature? Air intrusion? Or just water?

As a well-known old fart (architecturally, anyway), I prefer old, proven solutions. My go-to weatherstrip is the folded spring bronze, as pictured. I use it for door jambs, sill and head, and for double-hung windows. You'd have to go to extra trouble to get bronze nails; the usual nails sold are copper-plated steel.

For the meeting rail in a Dutch door, I've successfully used the shiplap and the folded spring bronze.

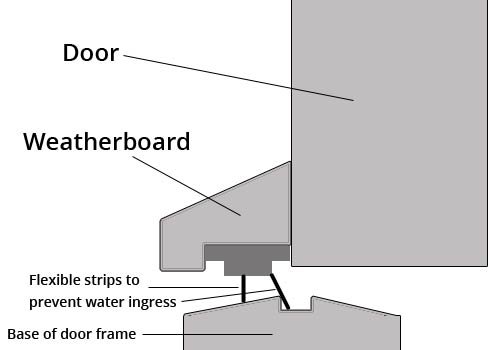

For your requirement of 'either open', your idea of a vinyl brush, as you show, will work. These things are sold in many variations; they don't have to show. I've used the one pictured and I recessed the aluminum extrusion into the bottom of the door. Important negatives of this sort of weatherstrip is that they have to have the right clearance; too large and they don't seal; too small and they don't close, and they wear rather quickly.

A good, easy way to keep water off the joint is to use a rain deflector. They can be bought, made of plastic or aluminum. I make my own; sawn to a trapezoidal cross section. Pictured is my kitchen door bottom with a painted Teak deflector, the bronze weatherstrip at the jamb, White Oak threshold that I made to accommodate the original marble sill and the shrinkage-lowered interior floor. The smears on the threshold are from the spring bronze sliding on the varnish.