If you consult Peggie's book the preferred arrangement for vent(s) is to have 2 - one either side as large and as straight as possible w straight bore thru hull no screens, baffles, etc.

You need to read it again, Don...'cuz I do NOT say that two vents are the preferred arrangement....see page 47:

"So the tank vent line should be as short, as straight, and as horizontal as possible, with no sags, no arches, and no bends. The minimum I.D of the hose (which is the “standard” size in use today, but for no reason other than being “standard” in fresh water and fuel tanks) is 5/8”. However, I recommend that it be at least 1” or even larger if the boat is large enough to let a larger vent thru-hull be cosmetically acceptable. Ideally, it should be no more than 3’ long, but no longer than 5’.

"If it has to be much longer, or

if running the vent line uphill at angle sharper than 45 degrees can’t be avoided,

or if it’s impossible to run a vent line that does not go around a corner,

it may be necessary to install a second vent line in order to create cross ventilation, or install some mechanical means of forcing air through the tank."

I dunno how you manage to translate that into "Peggie's preferred arrangement is two vents."

You didn't get this quite right either:

I see two reasons for a vent. The first is to provide a way to equalize the pressure inside and outside of the tank. This is both for when contents are added and when the tank is being pumped out.

Tank vents don't "equalize" pressure, they simply provide an escape for air displaced by incoming contents and a source of air to replace contents as they're drawn out. This applies to all tanks--fuel, water and waste. Aerobic/anaerobic matters only in waste tanks, both sewage and gray water.

Replies to several other comments:

A loop or U in the vent line will keep water out of the tank if the vent opening gets sprayed or rained on. Boats moving around plus wind can cause water to be pushed into the vent.

Only if the vent thru-hull is at the boat's waterline, which is a very bad location for it Spray, splashing or rain couldn't put enough water to notice into any vent. If you think it can, lay a 2 liter soda bottle on its side and aim a garden hose with the nozzle set to spray at it from just a foot away and see how much water you can put the bottle.

But even if splashing, rain and spray could put water into the tank, so what? It's obviously necessary to keep sea and rain water out of f.uel and water tanks, but we're talking about

sewage holding tanks here! A whole bucket full of water down the vent would only dilute it a little.

I'm not sure the location is critical as long as it is above the waterline

Location DOES matter a LOT! Your forward tank is vented correctly..in fact, ideally except for replacing the "vent" thru-hull with an open one! But as for your aft tank...an aerator is the only way to prevent odor out a vent through the transom. Boat builders vent out the transom in a misguided attempt to send odor away from the boat. It doesn't do the people downwind of your boat any favors though!

And finally...

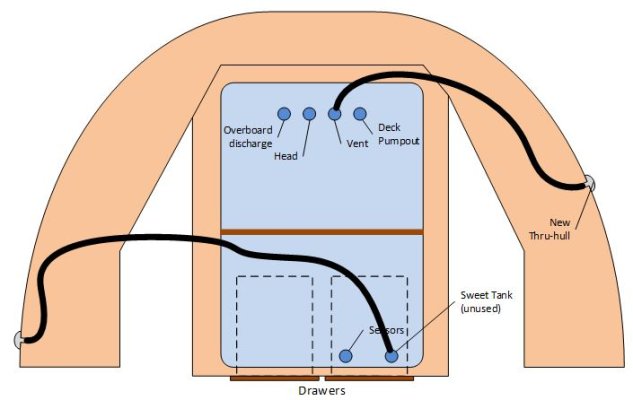

Lou...looking at the photo of your boat and going by your description of the tank location, I'd run a new 1"--or even 1.5"--vent line off the top of the tank at the forward end of it (installing a new vent fitting in a plastic tank is actually pretty easy, thanks to a little gadget called the Uniseal

UNISEAL ) running the line forward to ONE new open bulkhead or "mushroom" thru-hull. Your photo makes it appear that you can bring it out only about 3' aft of the bow, which would be ideal because air would be forced in--and thererfore also out again--to the tank when the boat is underway, on an anchor or even at the dock as long as there's even the lightest breeze. Using No-Flex Digestor

Noflex Digestor in the tank will ensure you'll never have odor out the vent.

--Peggie

You're forgiven. It was late...I'd had a long frustrating day and I was tired. So I over-reacted just a bit.

You're forgiven. It was late...I'd had a long frustrating day and I was tired. So I over-reacted just a bit.